Steel belt wheel type continuous casting machine with casting blank conveying mechanism for continuous casting lead belt

A technology of conveying mechanism and continuous casting machine, which is applied in the field of steel belt wheel continuous casting machine for continuous casting of lead strips, which can solve the problems of unguaranteed production, easy deformation, and great influence of self-weight, etc., so as to avoid casting billet hanging in the air and deformation Even fracture, enhance the effect of supporting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

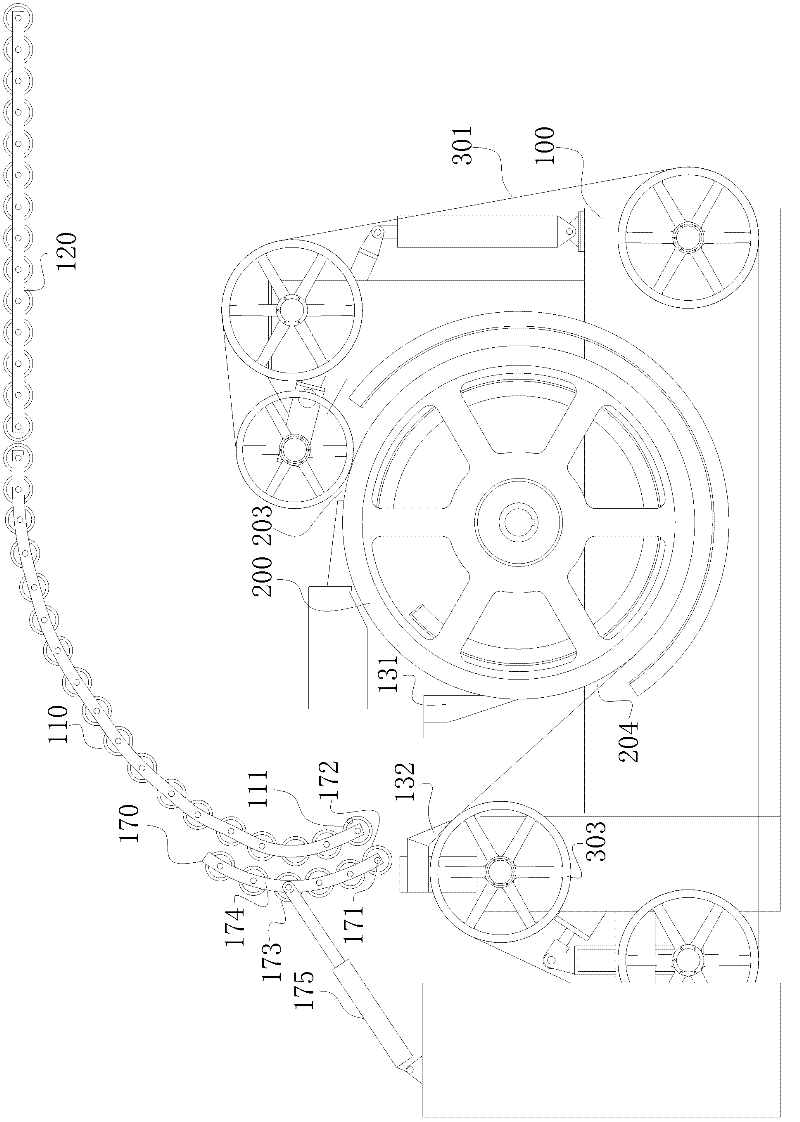

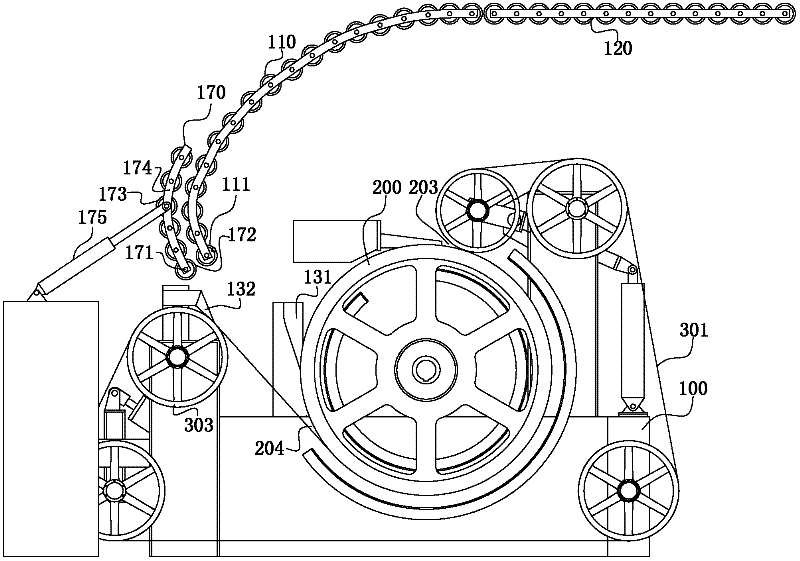

[0019] The steel-belt wheel-type continuous casting machine for continuous casting lead belt provided with a slab conveying mechanism of the present invention comprises a frame 100, a crystallization wheel 200, a steel belt wheel system, a headless steel belt 301, and a slab conveying mechanism; The outer cylindrical surface of the crystallization wheel 200 is provided with a concave crystallization cavity; the steel belt 301 is tightened by the steel belt wheel system and bypasses the crystallization wheel 200, and the part of the crystallization cavity of the crystallization wheel 200 is closed by the steel belt 301 to form a mold cavity One end of the cavity is the casting port 203, and the other end is the casting port 204; the billet conveying mechanism includes an approach bridge 110 and a conveying roller table 120, and one end of the approach bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com