Electronic device and production method of metal casing of electronic device

A technology for metal casings and electronic devices, which can be applied to metal casings, casings with display/control units, telephone communications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The electronic device provided by the present invention and the manufacturing method of the metal case of the electronic device will be further described in detail below with reference to specific implementation methods and accompanying drawings.

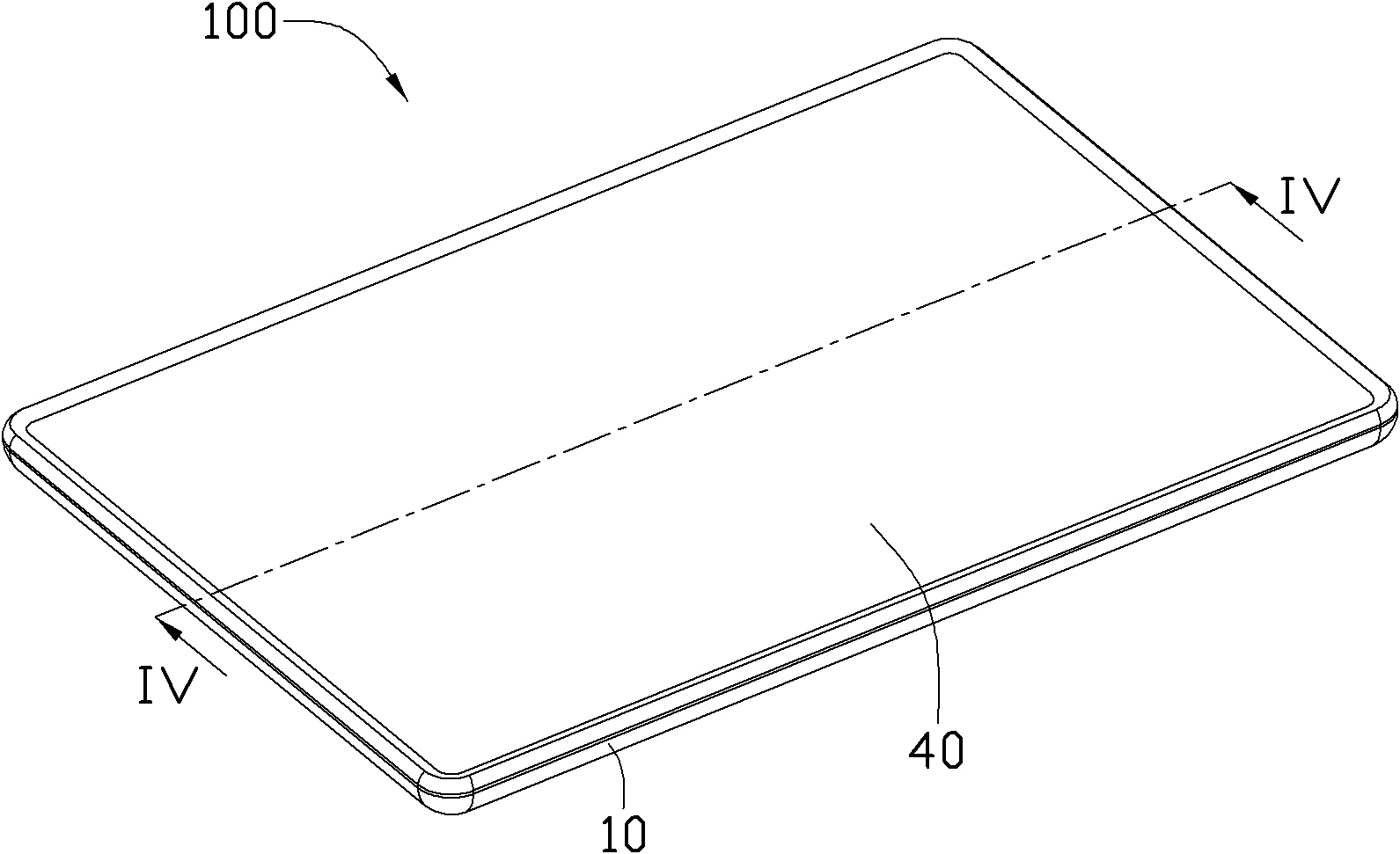

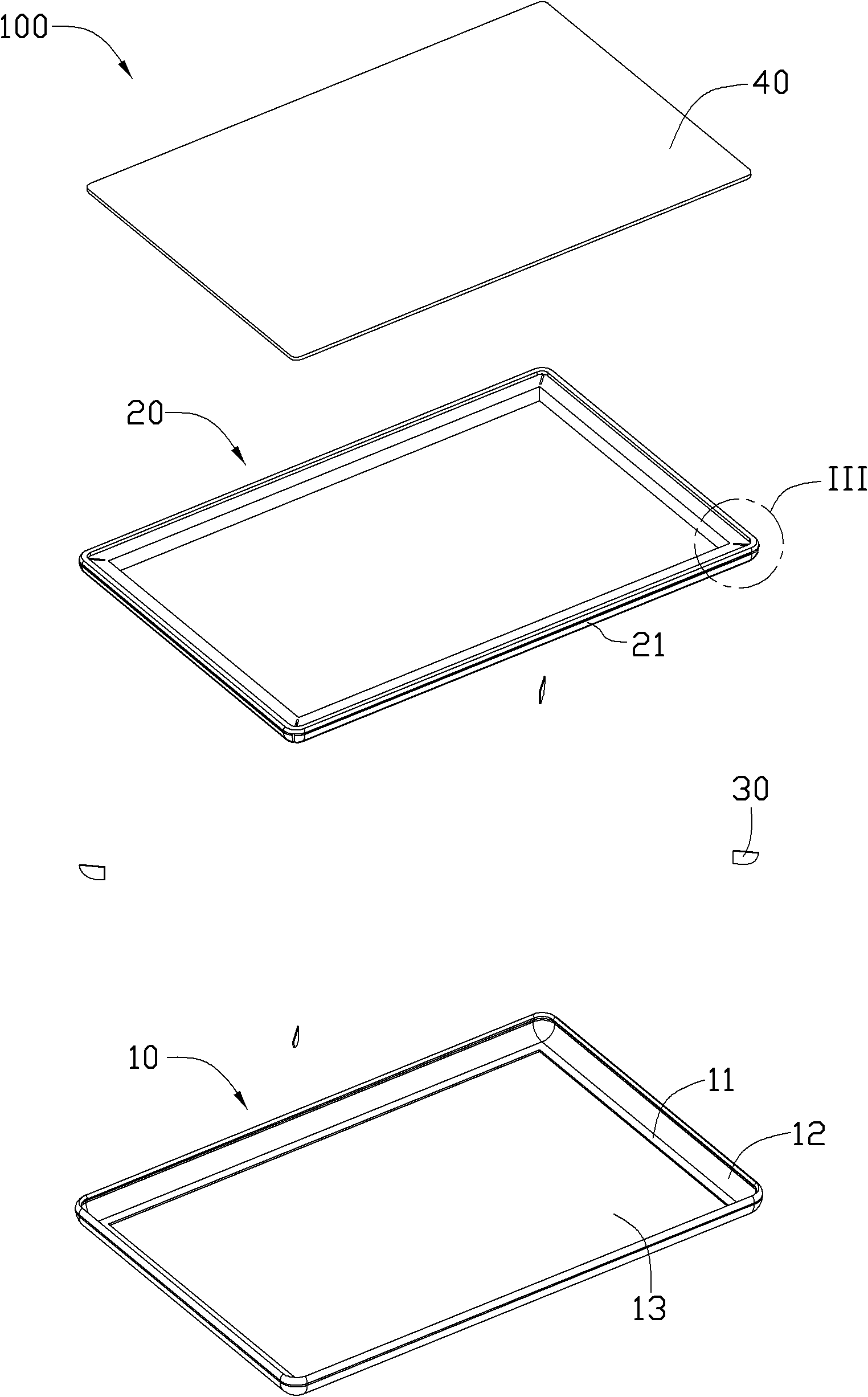

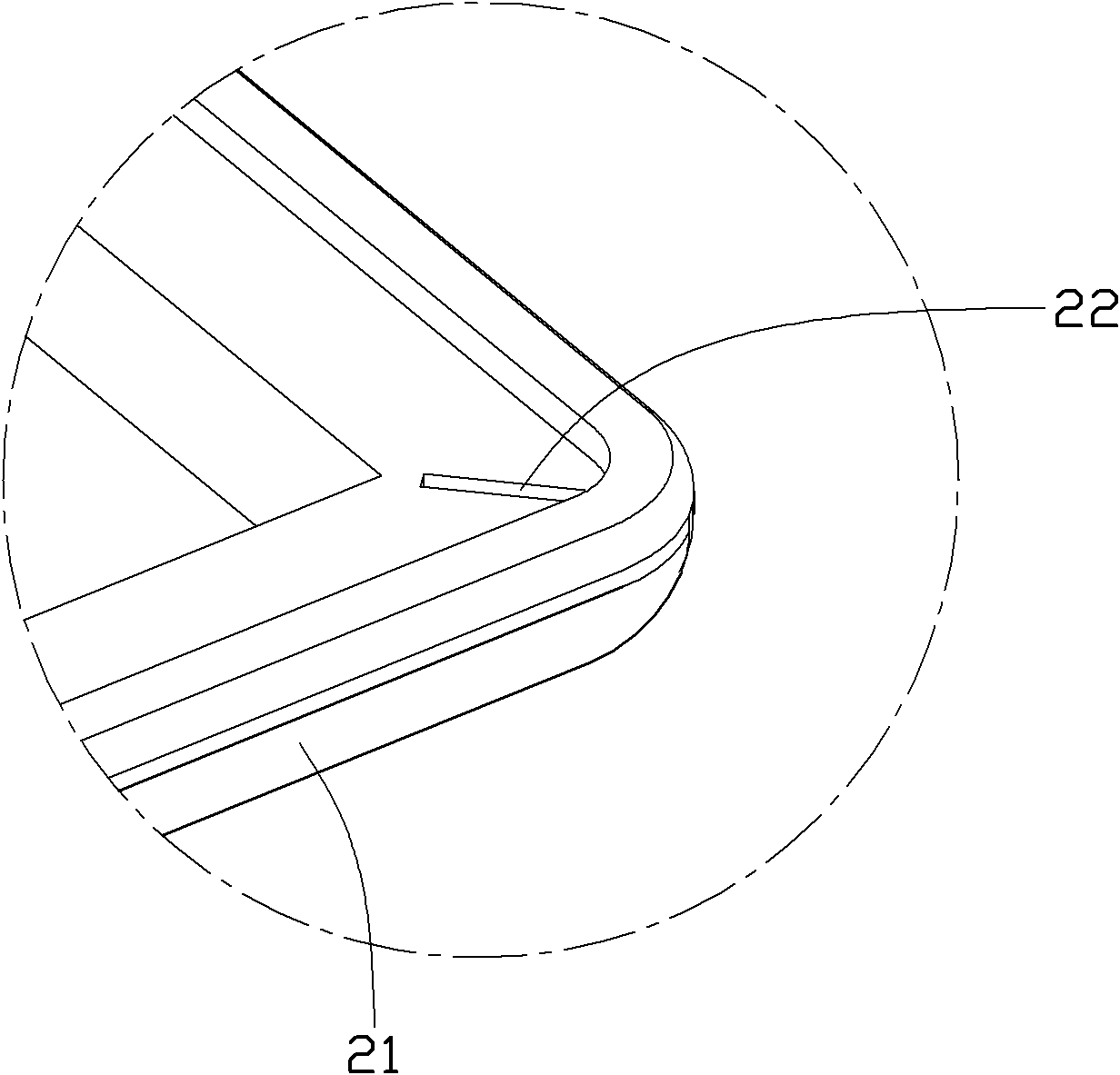

[0024] see figure 1 and figure 2 , the electronic device 100 includes various functional modules for realizing various corresponding functions. However, in order to save space, this embodiment focuses on the structure of the metal casing 10, the support frame 20 and the display screen 40 of the electronic device 100. . The electronic device 100 of this embodiment can be a touch computer, a mobile phone, an MP3 player, a PDA (Personal Digital Assistant), a digital photo frame, a liquid crystal display, and the like. In this embodiment, a touch-type computer is taken as an example for description. The support frame 20 is fixedly connected with the metal shell 10 . The display screen 40 is disposed on the supporting frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com