Sound-insulation wooden door and manufacturing method thereof

A wooden door and core board technology, applied in soundproof doors/windows, manufacturing tools, door leaves, etc., can solve the problems of high production and transportation costs, inability to guarantee the strength of the core layer, rough edges around the door board, etc., and achieve flexible layout and beautiful appearance Good performance and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

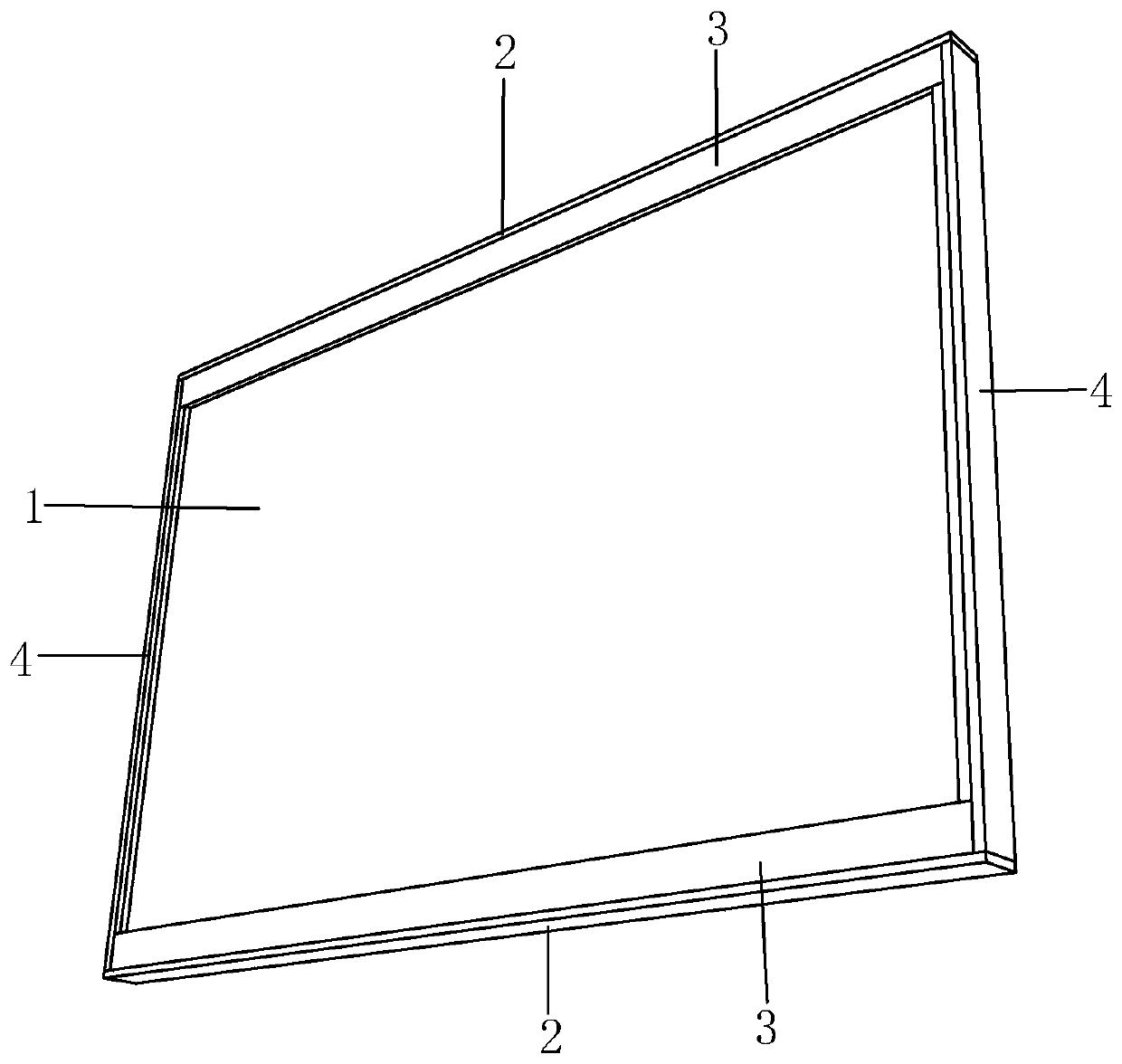

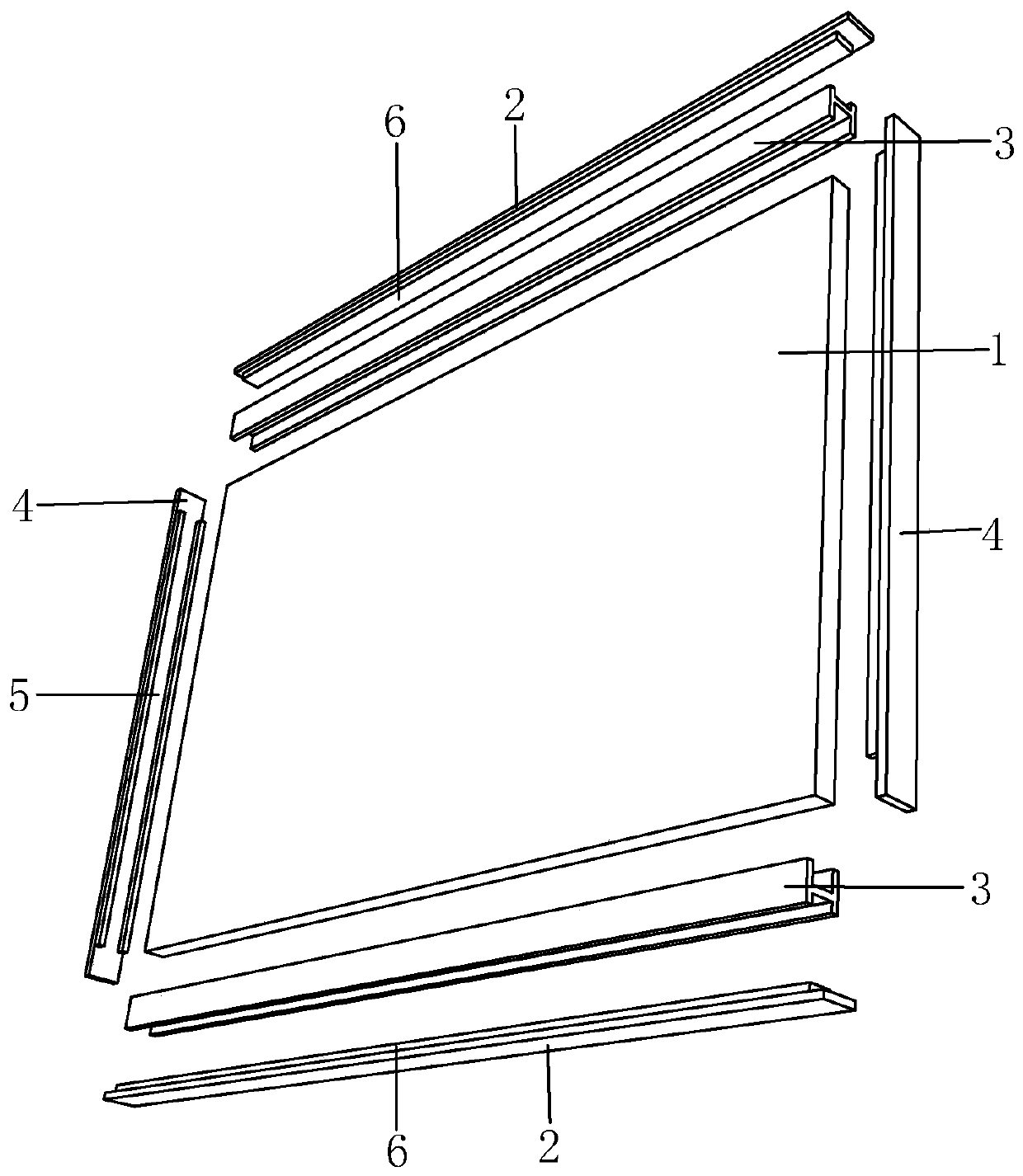

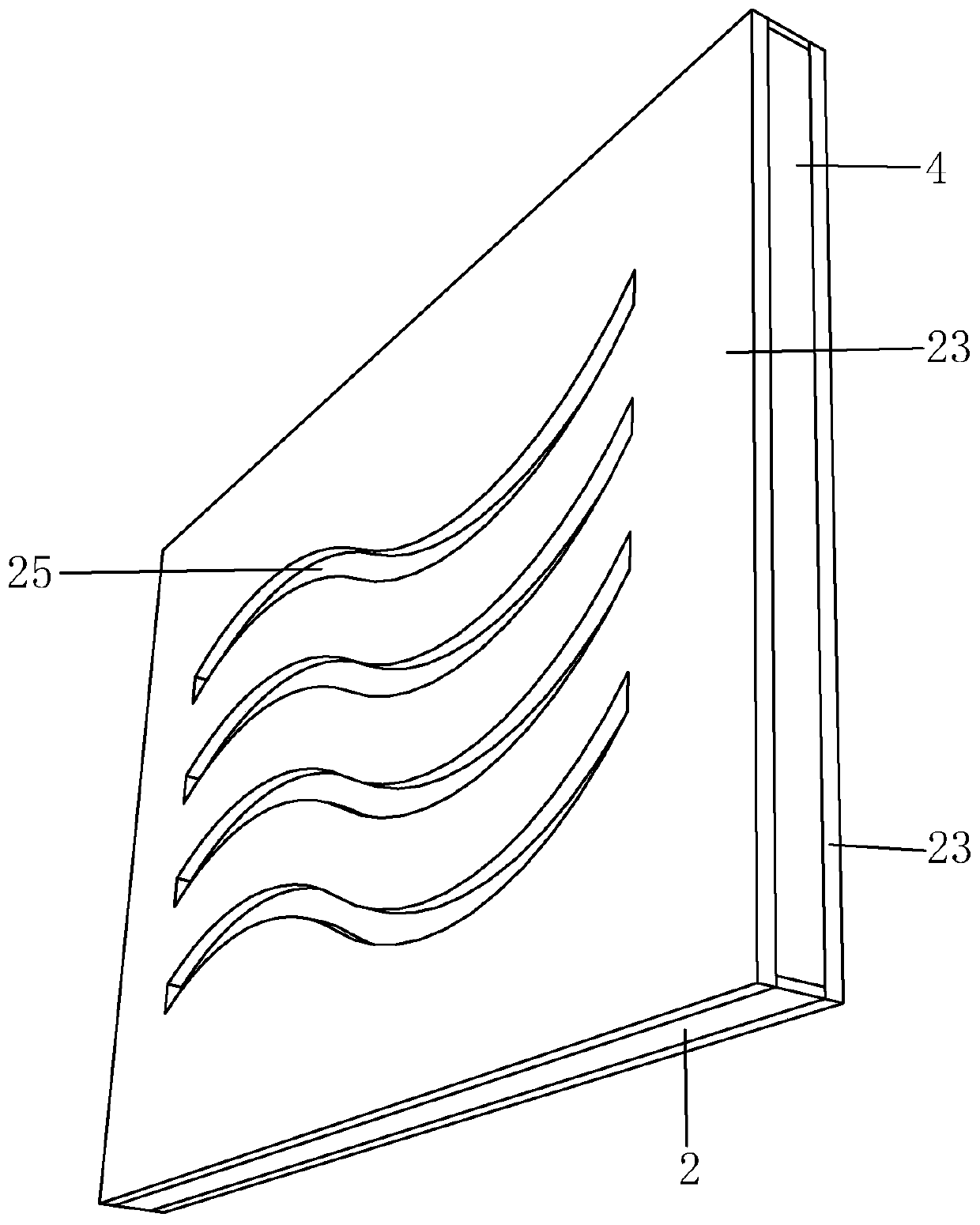

[0045] The sound-insulating wooden door includes a core board 1, and the periphery of the core board 1 is provided with a wrapping structure, and the joint between the wrapping structure and the core board 1 is coated with adhesive, which improves the connection between the wrapping structure and the core board 1 Strength, high reliability, not easy to disengage. The four edges of the core board 1 are protected by wrapping through the wrapping structure, which not only improves the overall aesthetics, but also avoids accidental scratches caused by the exposure of the raw edges of the core board 1, thereby improving safety. The wrapping structure includes side strips 2, H-shaped positioning strips 3 and wrapping strips 4. The wrapping strips 4 are arranged on the upper and lower sides of the core board 1. The board 1 is matched, and the edge strip 4 covers the side of the core board 1 through the slot 5, and the positioning and installation are fast and convenient, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com