Large-deformation composite material with flexible cellular structure and preparation method of large-deformation composite material

A composite material and cellular structure technology, applied in the field of flexible cellular structure composite materials and their preparation, can solve the problems of high stiffness of the matrix, difficult to obtain large deformation, easy to fracture, etc., to meet application requirements, good large deformation characteristics, combined with high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

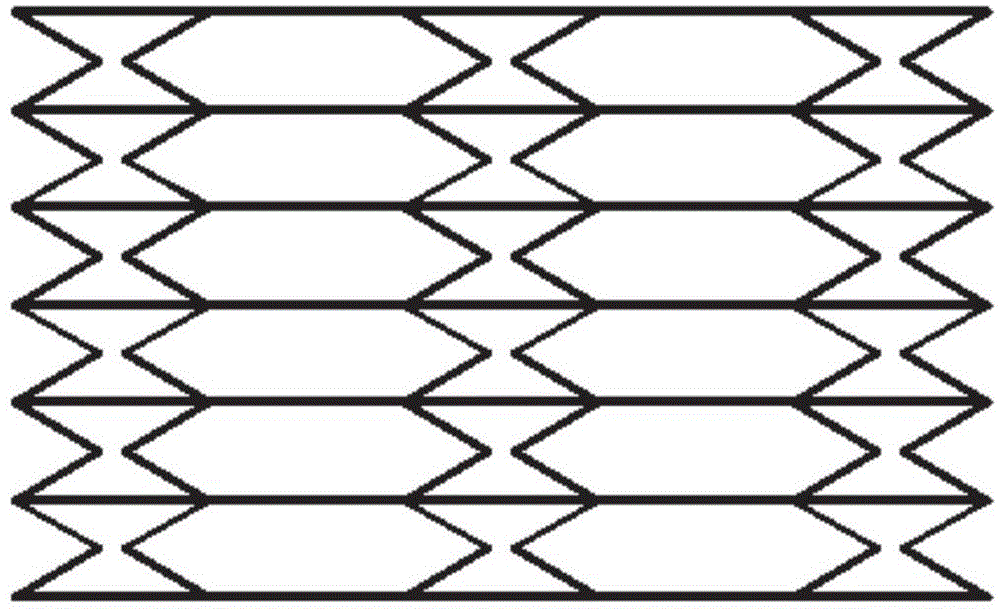

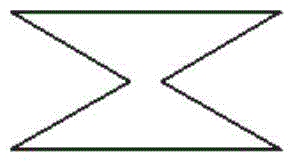

[0038] Embodiment 1: as figure 1 As shown, a large-deformation flexible cellular structure composite material includes several unit cell rows, and the adjacent unit cell rows are connected by a rigid carbon fiber composite material formed by carbon fiber cloth soaked in epoxy resin. The unit cell row includes several hexagonal unit cell structures and corresponding concave hexagonal unit cell transition structures, and the hexagonal unit cell structures and the concave hexagonal unit cell transition structures are sequentially arranged at intervals. Among them, the hexagonal unit cell structure is a two-layer structure, and the six cell walls of the inner layer are glass fibers; as Figure 5 As shown, the four cell walls to be deformed are impregnated with flexible epoxy resin to form the outer layer, and the remaining two cell walls are impregnated with epoxy resin to form the outer layer.

[0039] Wherein, the flexible epoxy resin comprises the following components, in part...

Embodiment 2

[0055] Embodiment 2: A large deformation flexible cellular structure composite material, including several unit cell rows, and the adjacent unit cell rows are connected by a rigid carbon fiber composite material formed by impregnating carbon fiber cloth with epoxy resin. The unit cell row includes several hexagonal unit cell structures and corresponding concave hexagonal unit cell transition structures, and the hexagonal unit cell structures and the concave hexagonal unit cell transition structures are sequentially arranged at intervals. Among them, the hexagonal unit cell structure is a two-layer structure, and the six cell walls of the inner layer are made of glass fiber; the four cell walls that need to be deformed are impregnated with flexible epoxy resin to form the outer layer, and the remaining two cell walls are made of rings. Oxygen resin infiltrates the molding to form the outer layer.

[0056] Wherein, the flexible epoxy resin comprises the following components, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com