Conductor payoff rack

A pay-off frame and wire technology, which is applied to overhead lines/cable equipment, conveying filamentous materials, thin material handling, etc., can solve problems affecting work progress, construction safety hazards, and wire coil drop, etc., and is easy to promote , Improve work efficiency and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are further described below in conjunction with the drawings:

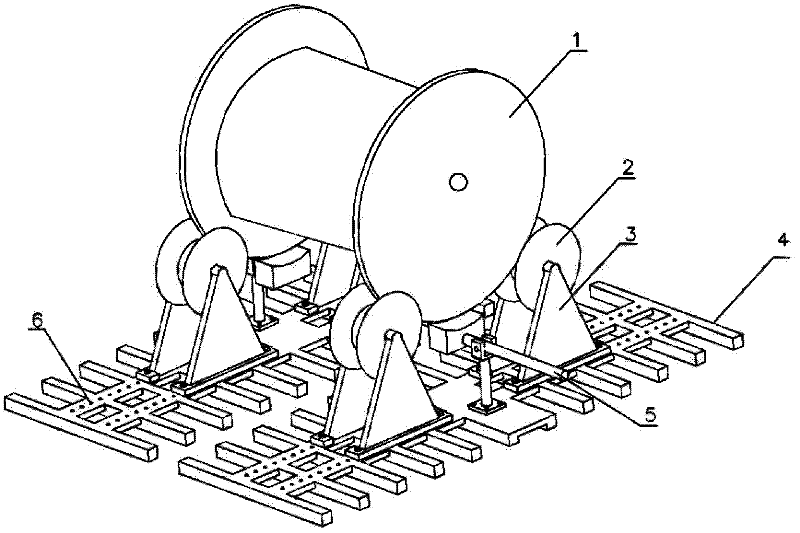

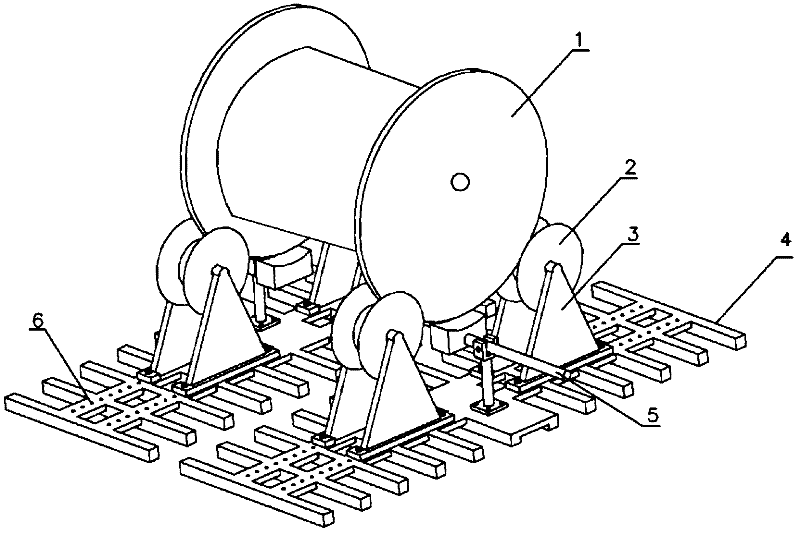

[0014] As shown in the drawings, the present invention is mainly composed of a roller 2, a bracket 3, a base 4, and a brake device 5. The four brackets 3 are respectively provided on the rollers 2 to support the wire reel. The four brackets 3 are divided into two groups, which are respectively placed on the two rows of bases 4, and the two brake devices 5 are placed under the wire reel, respectively installed in two rows On the base 4.

[0015] The bracket 3 is a regular triangle structure. Each pay-off bracket has three internal and external sub-brackets. The upper ends of the two sub-brackets are connected by a central axis. The lower part of the bracket is placed on the two main supports of the base 4 with perforations on both sides. The screw is inserted into the perforation to realize the connection with the base 4.

[0016] The roller 2 is of a concave type, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com