Sealing structure of powder box

A technology of sealing structure and powder box, which is applied in electrography, optics, instruments, etc. It can solve problems such as inconvenient operation, powder leakage, and poor adhesion effect, so as to maintain adhesion and scalability, easy operation, and high efficiency. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

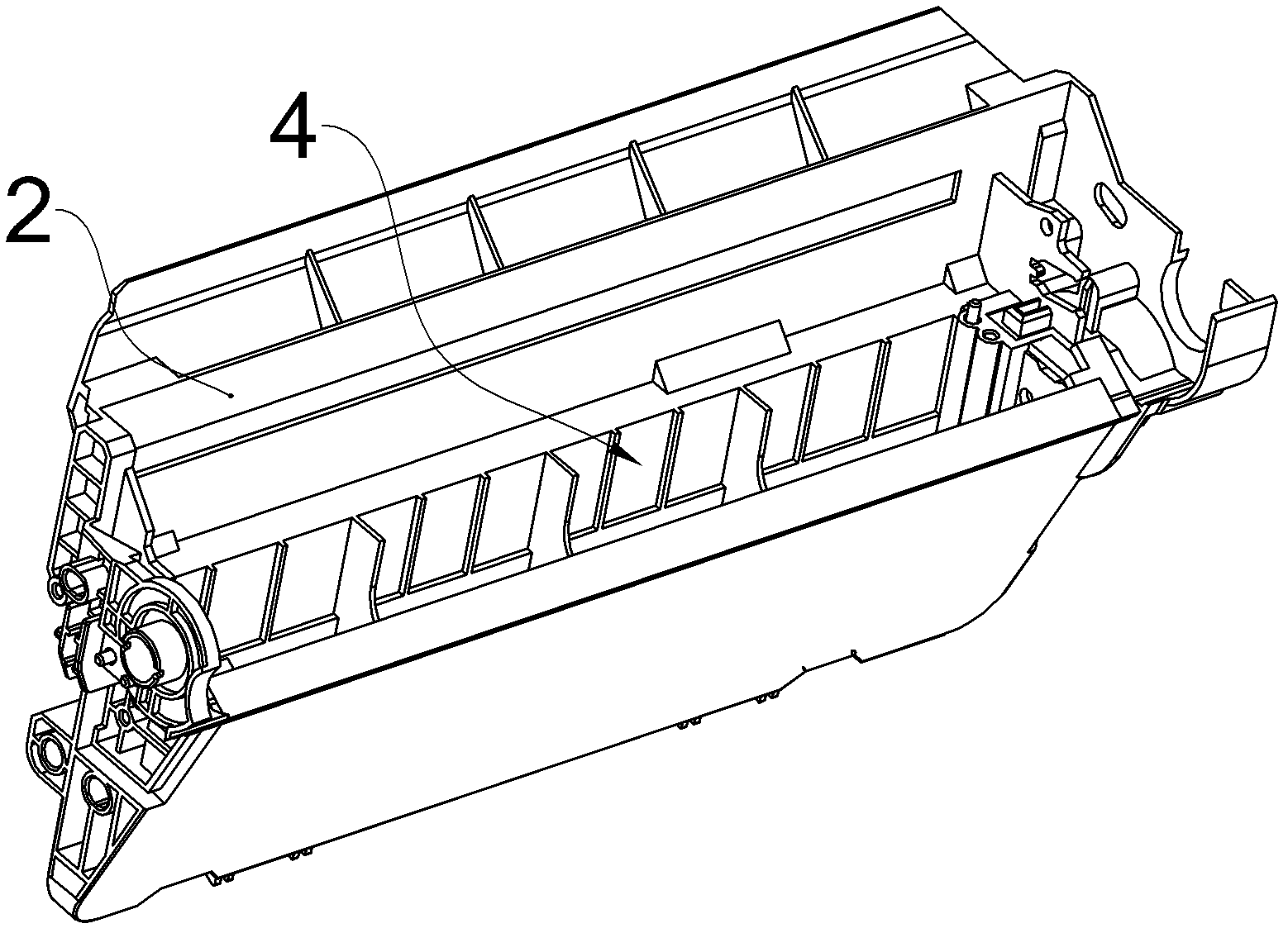

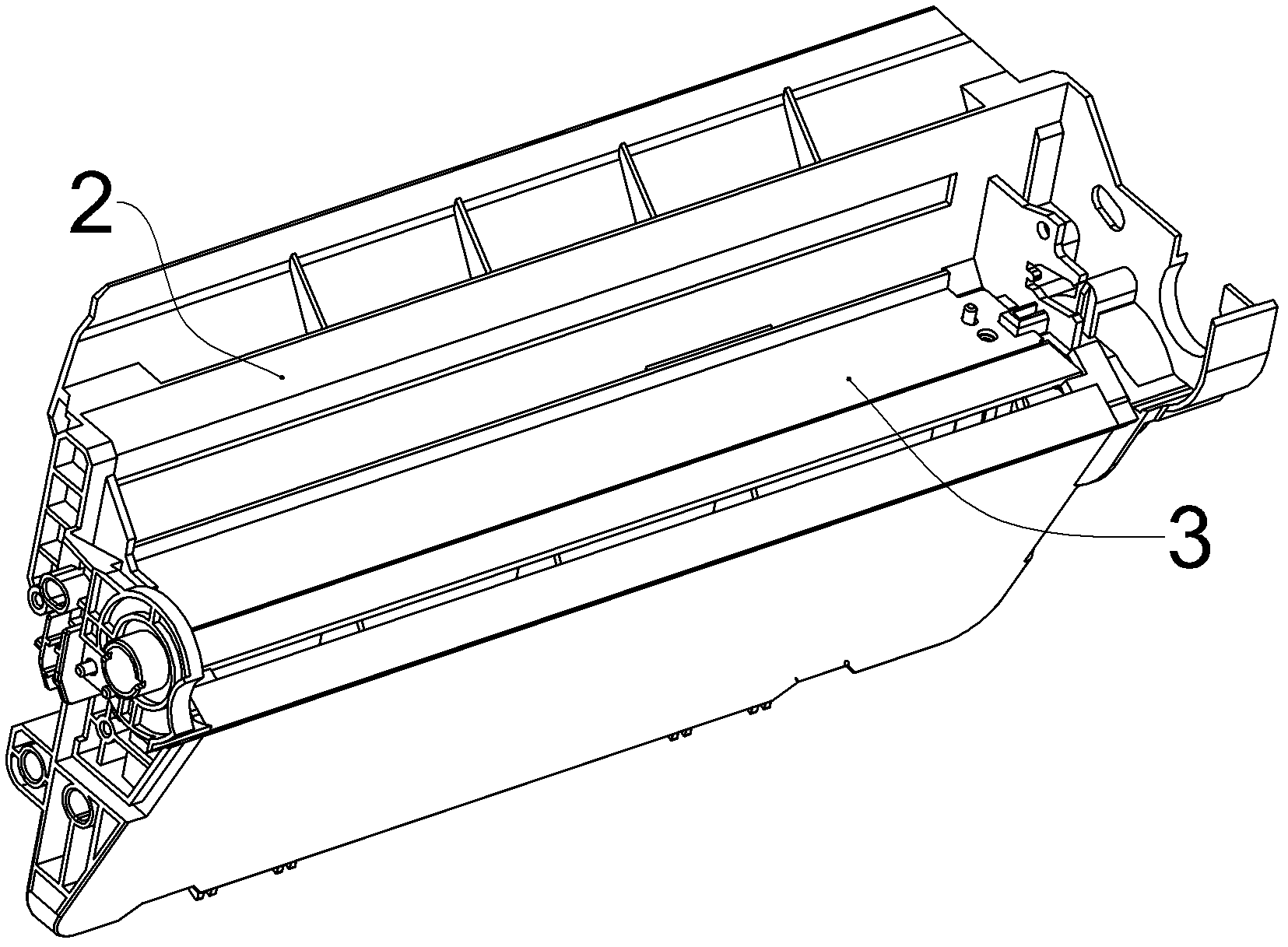

[0022] figure 1 Shown is a waste toner bin assembly 1 that adopts the powder box sealing structure of the present invention, see figure 2 and image 3 The waste toner bin assembly 1 includes a waste toner bin frame 2 and a cleaning scraper 3. The waste toner bin frame 2 has an opening 4 for recycling toner. The cleaning scraper 3 is fixed on the waste toner bin frame 2 by screws or other means. There are 4 openings. The waste toner bin frame 2 is a plastic part, and the cleaning scraper 3 is a metal part. The cleaning blade 3 is placed laterally at the opening 4 , and the lower edge 31 of the cleaning blade 3 is in contact with the unshown photosensitive drum, so as to scrape off the toner on the photosensitive drum and collect it into the waste toner bin frame 2 . In order to prevent the waste toner in the waste toner bin frame 2 from leaking between the waste toner bin frame 2 and the cleaning scraper 3, the junction of the waste toner bin frame 2 and the cleaning scrape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com