Medium concentration hydraulic double disc stuff grinder

A double-disc grinding, hydraulic technology, applied in pulp beating/refining method, textile and papermaking, fiber raw material processing, etc., can solve problems such as low efficiency, and achieve the effect of simple adjustment structure, balanced beating specific pressure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

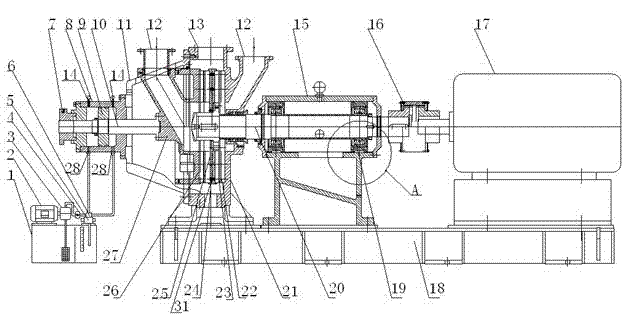

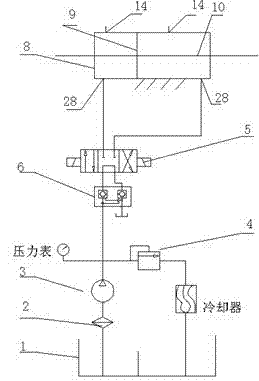

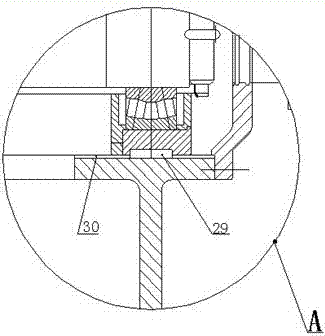

[0031] The structure of the medium-consistency hydraulic double-disc refiner of this embodiment is as follows: figure 1 As shown, it includes two parts: the hydraulic adjustment unit and the body of the medium-consistency double-disc refiner. The hydraulic adjustment unit consists of an oil tank 1, a hydraulic pump 3, an oil pump motor 2, an electromagnetic directional valve 5, a pressure regulating valve 4, a pressure maintaining valve 6, The hydraulic cylinder 8 and the piston 9 and the piston rod 10 in the hydraulic cylinder 8 are composed; the medium-consistency double-disc refiner body consists of a double-disc refiner shell 21, a shell cover 11, a left fixed disc seat 27, a left fixed disc 26, a left fixed disc Turntable 25, turntable seat 24, right turntable 23, right fixed disk 22, shaft 20, bearing body 19, shaft coupling 16, motor 17 and movable base 18 form.

[0032] The bottom of the hydraulic cylinder 8 is provided with an oil inlet 28, and the top is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com