Sealed deslagging method of fluidizing chlorination furnace

A technology of fluidized chlorination furnace and slag, which is applied in the direction of fluidized bed furnace, furnace, furnace type, etc., can solve the adverse effects of production equipment staff, environmental pollution, corrosion and other problems, achieve good promotion and application value, and solve environmental problems and the effect of gas corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

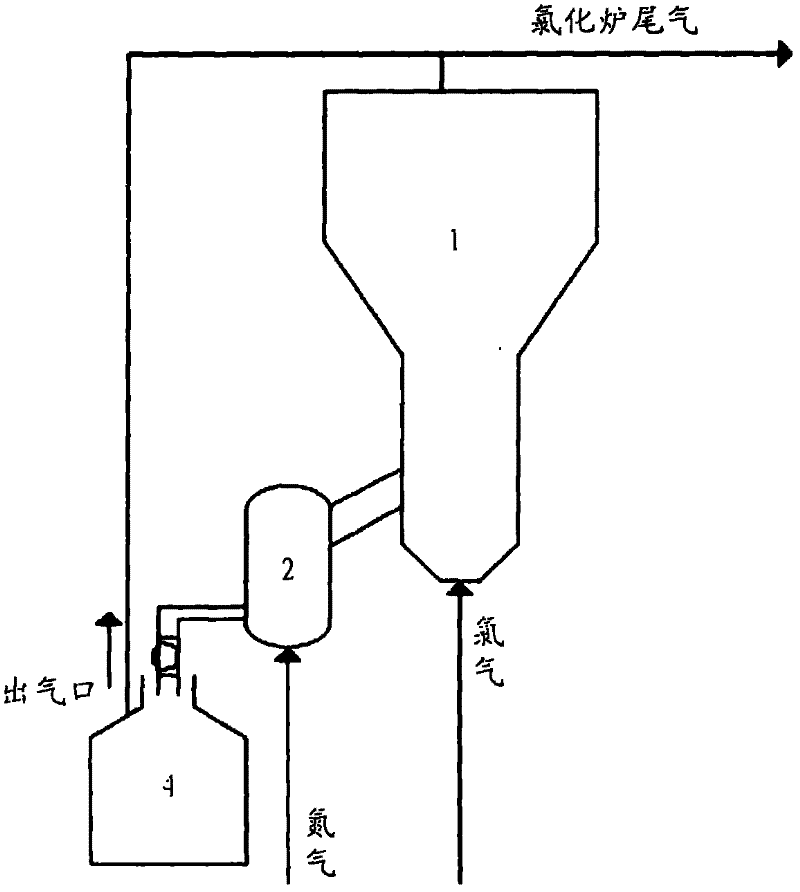

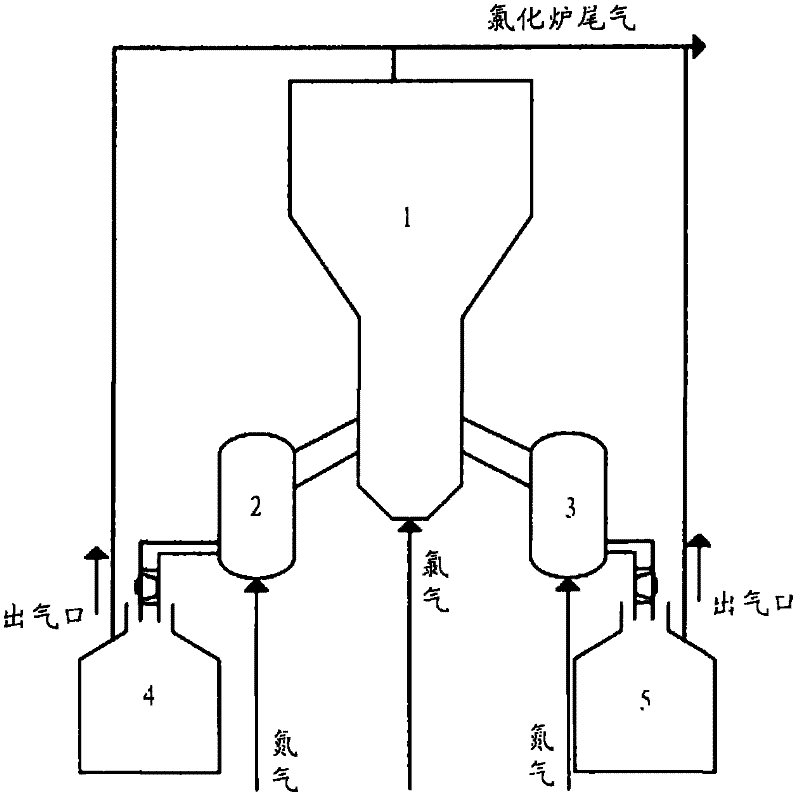

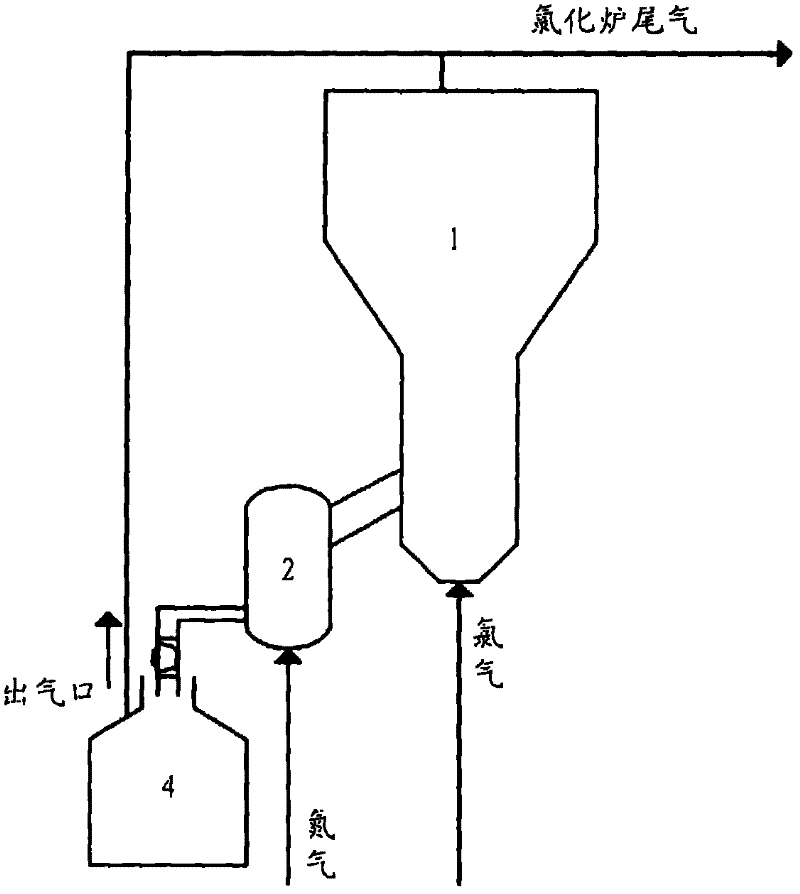

[0013] The closed slagging method of the fluidized chlorination furnace of the present invention will be described below in conjunction with specific examples.

[0014] The closed slagging method of the fluidized chlorination furnace of the present invention specifically comprises the following steps: discharging the slag produced in the fluidized chlorination furnace into a closed slagging tundish; Purify to obtain purified slag and mixed gas; discharge the purified slag and at least a part of the mixed gas into the slag receiving tank; make the at least part of the mixed gas pass through the negative pressure connected to the tail gas system in the slag receiving tank The pipeline is discharged to the tail gas system, and the purified slag is obtained in the slag receiving tank.

[0015] Wherein, the purge gas may be nitrogen or an inert gas. Preferably, the purge gas is nitrogen.

[0016] In addition, a gas distributor for feeding purge gas into the slag discharge tundish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com