Polishing machine for copper pipe of crystallizer

A crystallizer copper tube and polishing machine technology, applied in the field of polishing machines, can solve the problems of polishing surface damage, low polishing efficiency, different polishing texture directions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

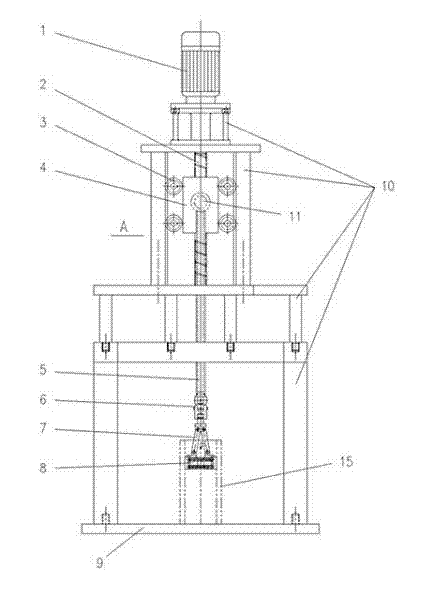

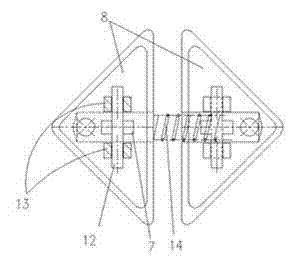

[0009] Such as figure 1 , 2 , Shown in 3: 10 is a frame, which adopts section steel welding to make. A vertical motor 1 is fixedly connected to the top of the frame 10 by bolts. The output shaft of the motor 1 is connected with the ball screw 2.

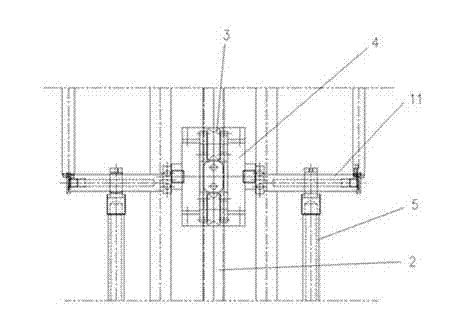

[0010] The screw nut that matches with leading screw 2 is fixed on mobile car 4 inner center position, and the both sides of mobile car 4 are symmetrically equipped with roller 3, and roller 3 is four, and every side up and down direction is provided with two. Roller 3 matches with the track of vertical direction on the frame 10. When the motor 1 drives the leading screw 2 to rotate, the mobile car 4 can be driven to move up and down along the track on the frame 10 by the screw nut.

[0011] The other two sides of mobile vehicle 4 are symmetrically fixedly installed with crossbeam 11, and 5 are connecting rods, and a connecting rod 5 is connected on the crossbeam 11 on each side, and its connection mode can be through the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com