Full-automatic door body butt-welding machine

A butt welding machine, fully automatic technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., to achieve the effect of accurate solder joints, labor saving, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

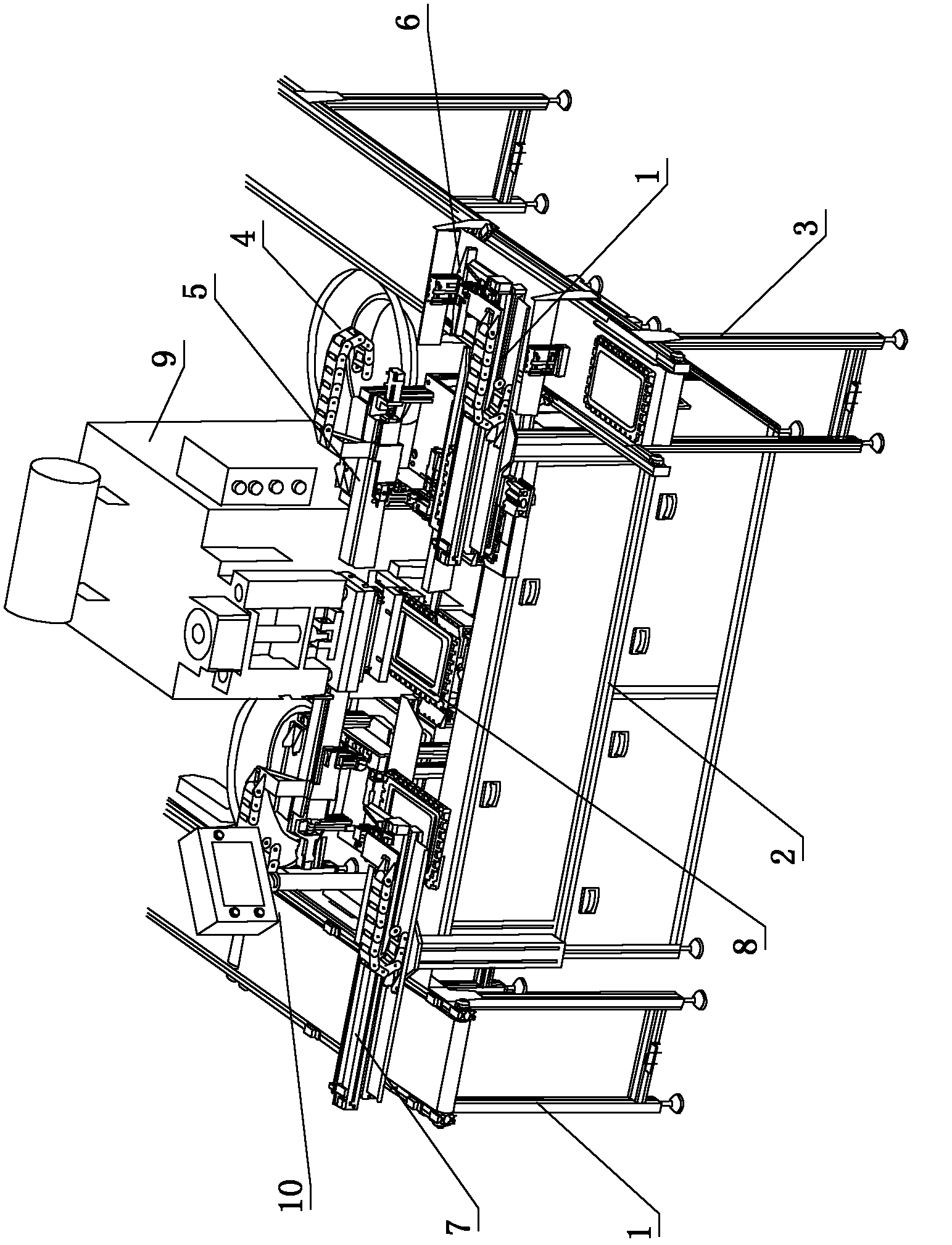

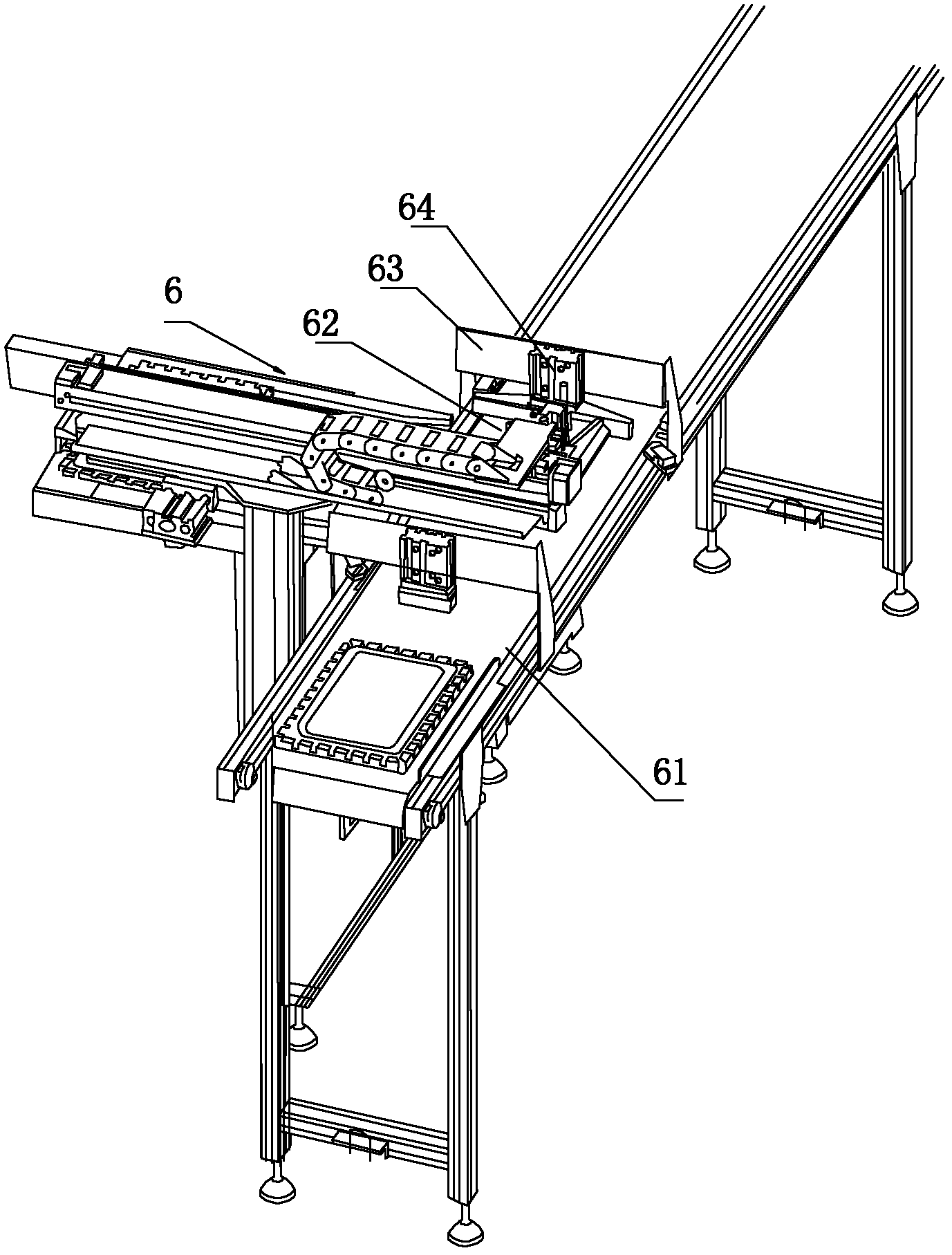

[0028] Attached below Figure 1-5 The present invention is described further:

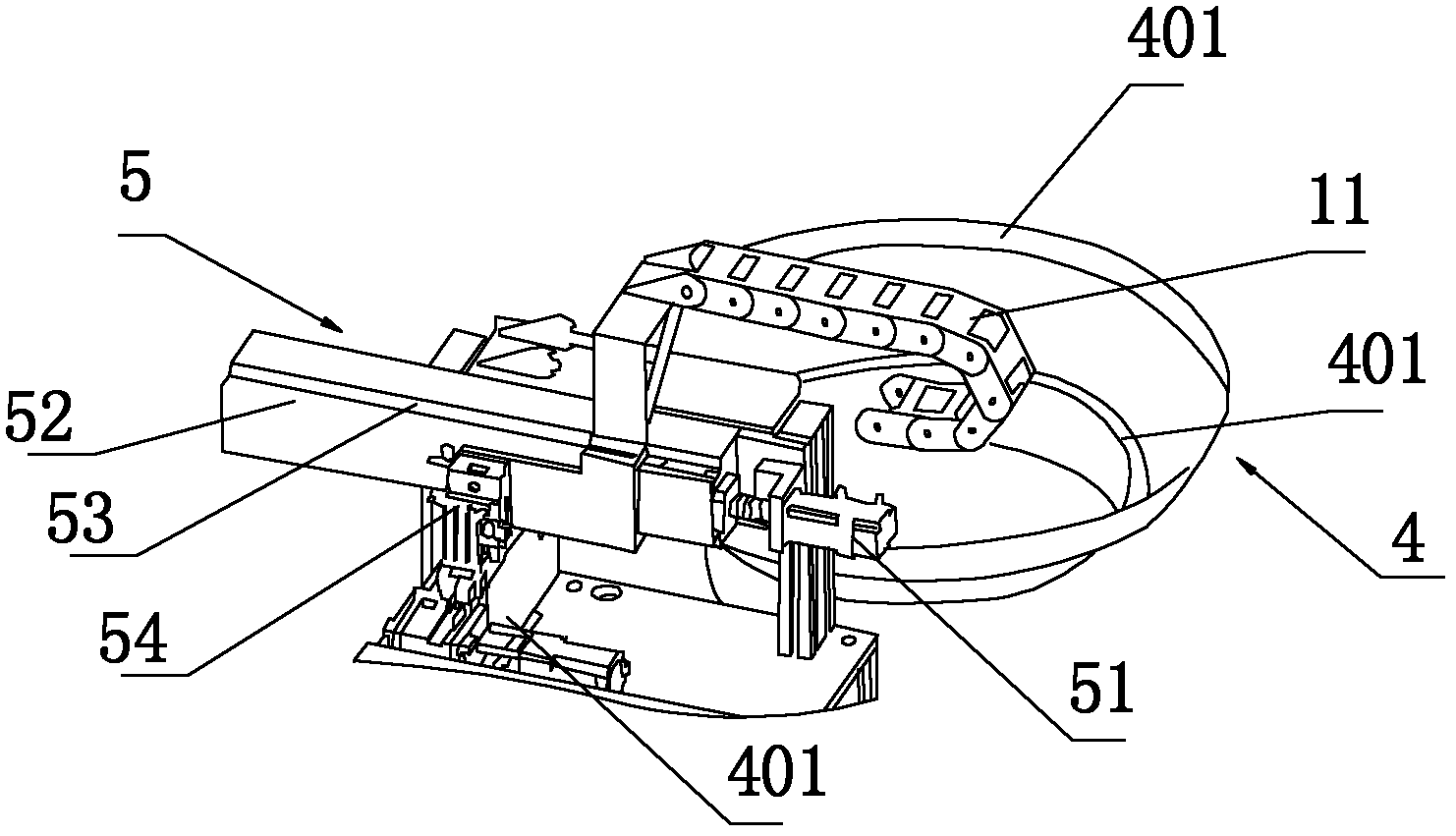

[0029] The full-automatic door butt welding machine of the present invention comprises a left machine base 1, a main machine base 2, and a right machine base 3 for bearing, and the said machine base is provided with a leg 11; A feeding module 4 (such as a door body buckle); and a retrieving module 5 arranged on the main base for transferring solder (such as a door body buckle) from the feeding module to the next operation link; and a An introduction device 6 arranged on the left machine base for importing workpieces; and an export device 7 arranged on the right machine base for exporting the welded workpieces; The module transmits the workpiece to the delivery device's delivery module 8; and a welding module 9 for welding the workpiece; and a control module 10 for the control of the butt welding machine system.

[0030] The feeding module includes left and two feeding devices 40. The feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com