U-shaped electromagnetic band gap circuit board with low-frequency simultaneous switching noise inhibiting function

An electromagnetic bandgap and switching noise technology, applied in printed circuit components and other directions, can solve the problems of inability to effectively suppress low-frequency simultaneous switching noise, reduce equipment reliability, malfunction of electronic devices, etc., to reduce the difficulty of etching, The effect of improving production efficiency and reducing the interference of high-frequency signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings.

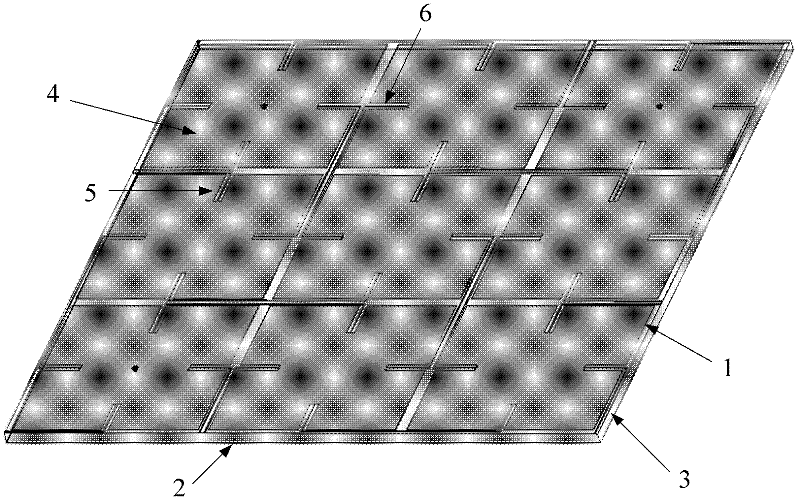

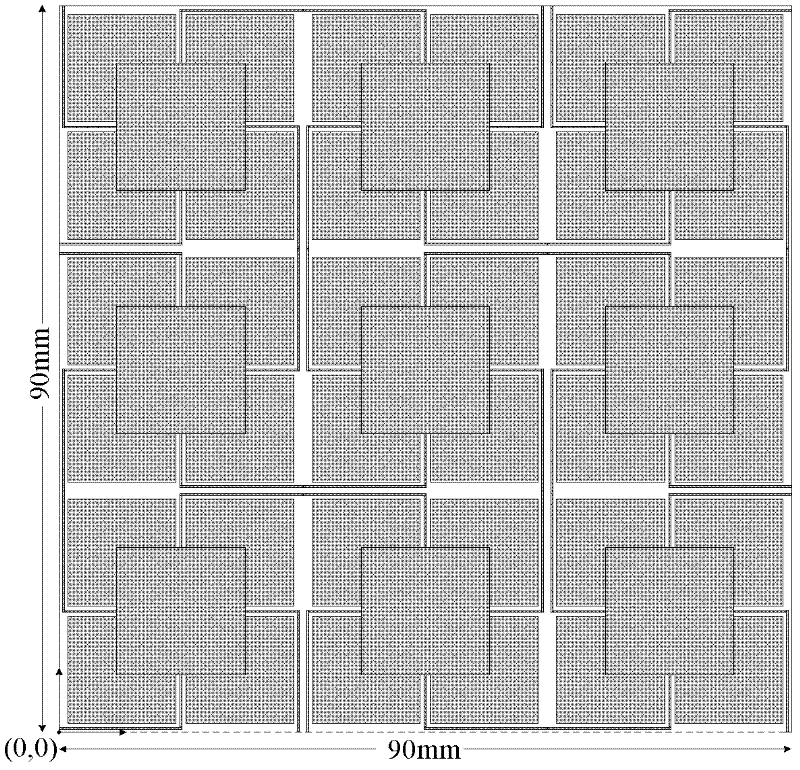

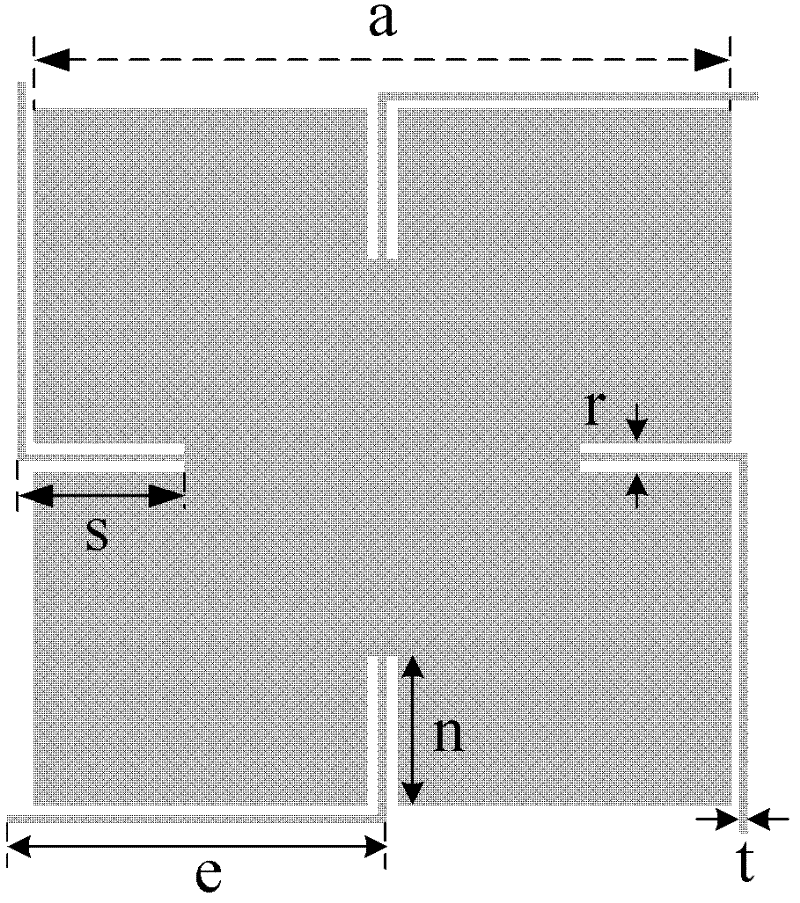

[0019] refer to figure 1 with figure 2 , The 3×3U electromagnetic bandgap circuit board of the present invention includes: an electromagnetic bandgap layer 1 , a ground layer 2 and a dielectric layer 3 . Among them, the electromagnetic bandgap layer 1 and the formation 2 are made of copper, and the relative permittivity is 1; the dielectric layer 3 is made of FR4 material with a thickness of 0.4mm, and the relative permittivity is 4.4; the electromagnetic bandgap layer consists of 9 electromagnetic bandgap Unit 4 is connected to form. in:

[0020] For the electromagnetic bandgap unit located on the left side of the first row, the first segment of the L-shaped connecting line in the left rectangular slot is rotated 90 degrees and folded upwards to the second straight line, and the L-shaped connecting line in the right rectangular slot is first The first sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com