Aviation mapping camera object lens center type shutter mechanism

A shutter and objective lens technology, applied in the field of aerial cameras, can solve problems such as high motor speed, large proportional coefficient, and affecting imaging quality, and achieve the effect of reducing the number of blades and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

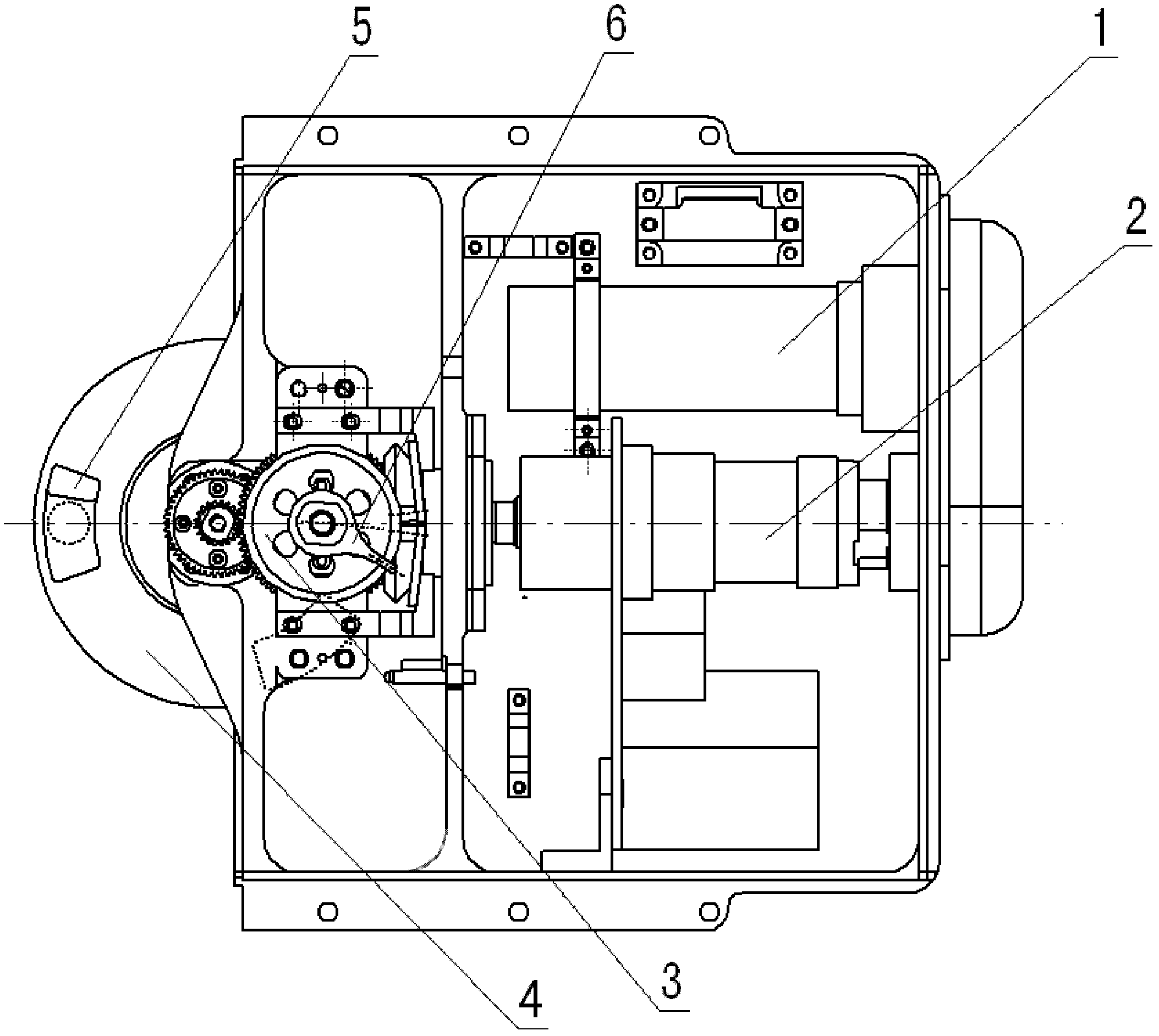

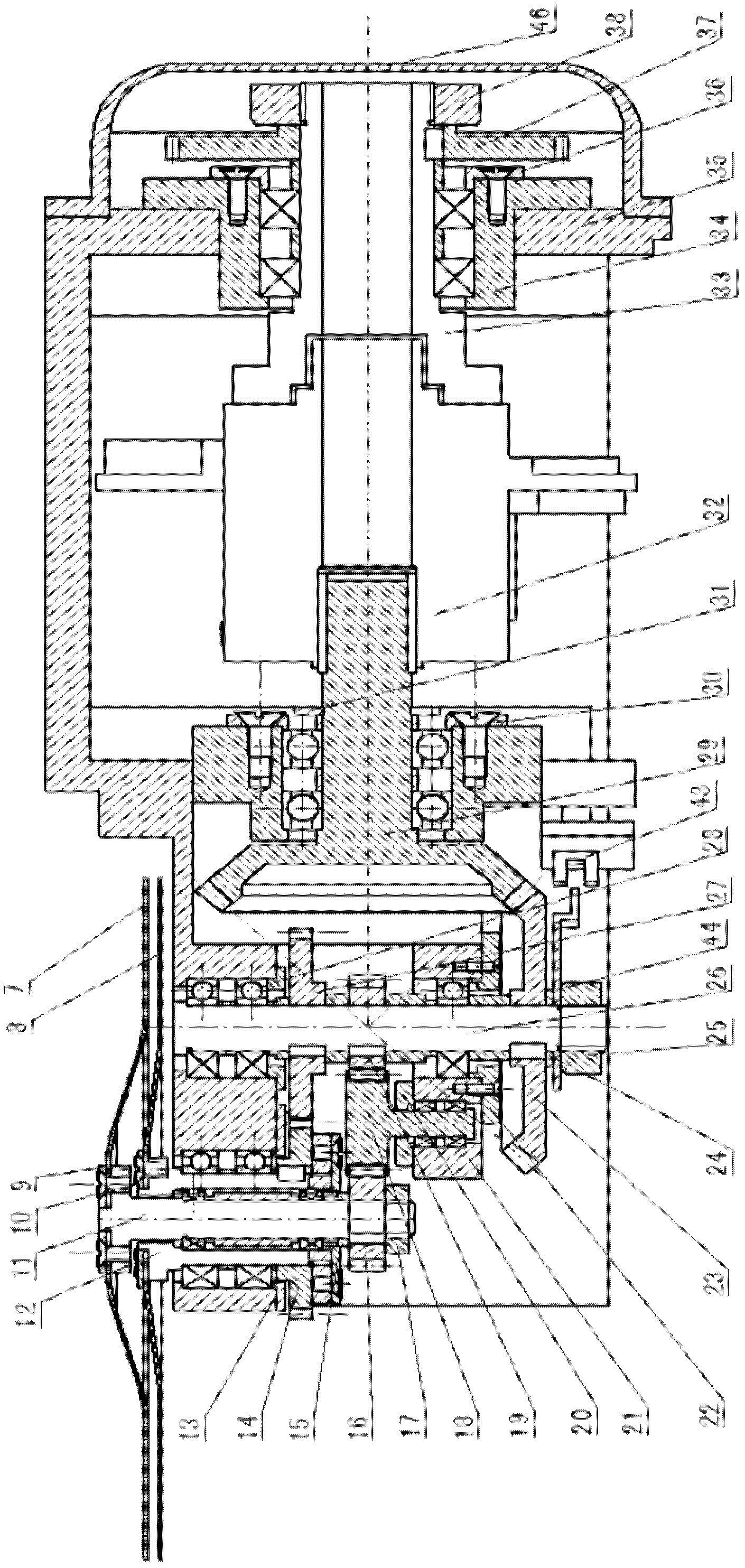

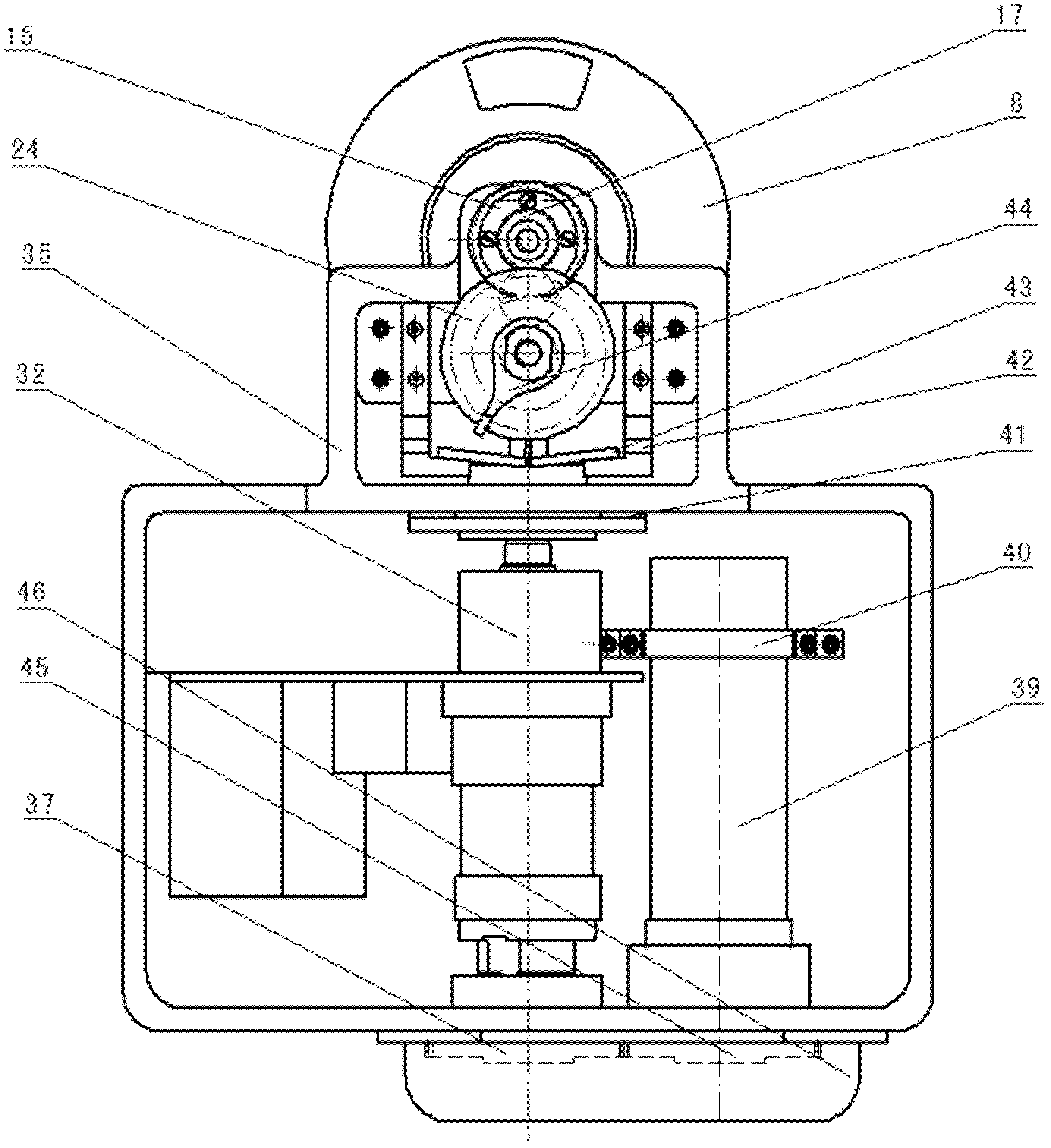

[0015] The invention according to figure 2 and image 3 The structure shown is implemented. Among them, the materials of the forward vane 8 and the reverse vane 7 are all made of high elastic modulus carbon fiber (M40) material impact molding; the clutch 32 of one week is the CB-4 clutch of the model CB4-CW-24DC-10H9 of Shanghai Kabei Company. The starting and stopping time of this clutch is very short, can bear larger torque, and has self-locking performance; The high-speed motor 39 selects the high-speed motor that the model of Maxon Company is RE30-268214 for use; Motor secondary transmission gear 37, motor primary transmission Gear 45, forward secondary gear 14, forward primary gear 27, reverse secondary gear 18, reverse primary gear 19, and reverse tertiary gear 16 are all made of 1Cr17Ni2 and surface quenched, with a hardness of 28-32HRC. The precision grade is 5-6-5gGB2363-90; the material of the second-stage bevel gear 23 and the first-stage bevel gear 29 is 1Cr17Ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com