Greenhouse-type double-heat-collecting double-heat-preserving solar-energy heat-pump drying device

A solar heat pump and drying device technology, applied in the field of solar energy utilization, can solve the problems of not conforming to the low-carbon economy, long drying cycle, poor thermal insulation effect, etc., to promote circular economy and protect the ecological environment, the drying and dehydration process is clean, The effect of accelerating the dehydration of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

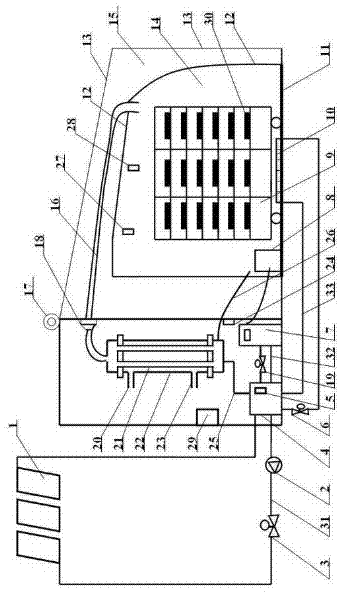

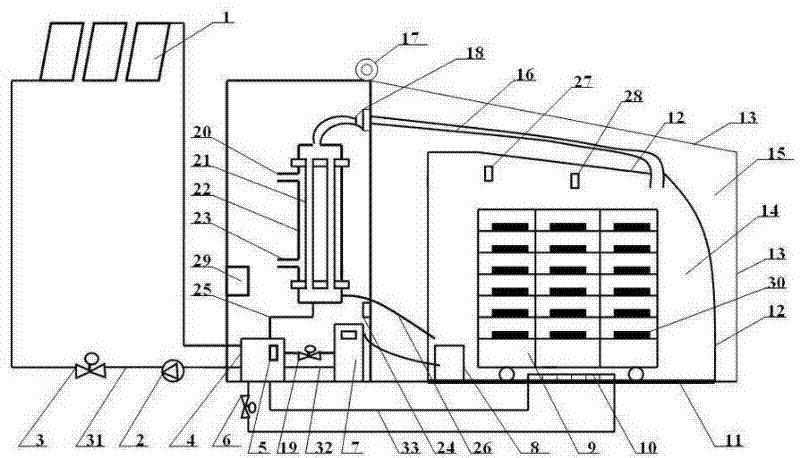

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

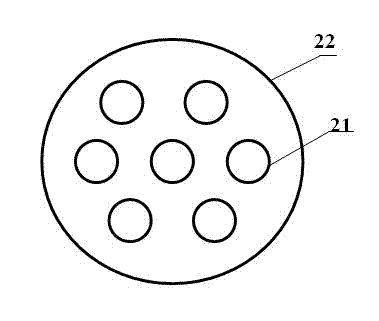

[0024] like figure 1 , figure 2 As shown, a greenhouse-type double-collection double-insulation solar heat pump drying device includes a drying unit, a solar heat collection unit, an auxiliary heating unit, a condensation dehumidification waste heat recovery unit, and an automatic monitoring and control unit. The solar heat collection unit consists of Consisting of a self-collecting unit and an external heat-collecting unit, the self-collecting unit is located above the drying unit, and the external heat-collecting unit is located on one side of the drying unit; the drying unit is composed of a drying chamber 14 and a light-absorbing shell 12 And the material support 9 that is located in the drying chamber 14, the bottom of the drying chamber 14 is also provided with a thermal insulation floor 11 made of polystyrene board; The solar greenhouse 15 is surrounded by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com