Aluminium electrolyzer cathode structure capable of reducing voltage and improving current distribution

A current distribution and aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of large cathode voltage drop, lower heat preservation degree, and lower current efficiency of electrolytic cells, so as to improve corrosion resistance, lower upper surface temperature, and lower cathode resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

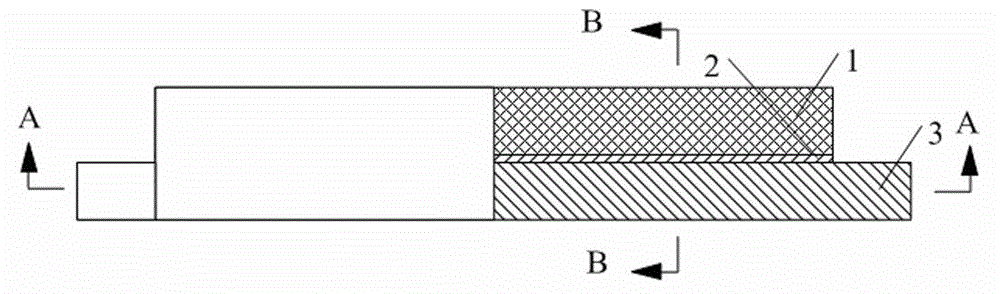

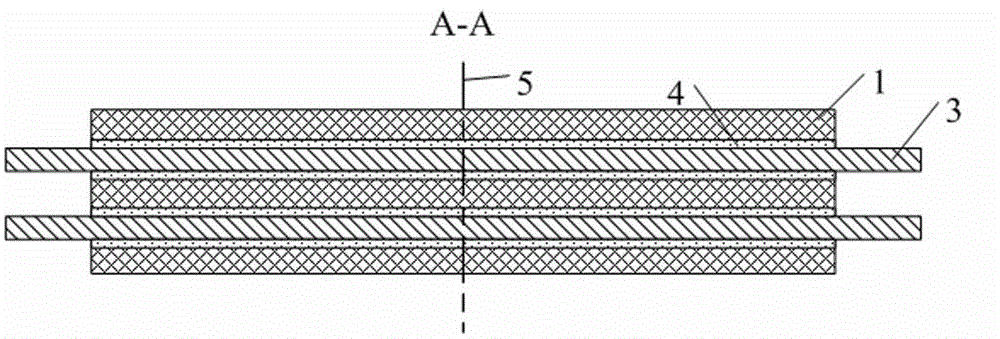

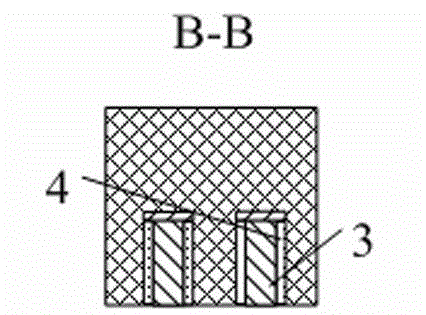

[0037] Aluminum electrolytic cell cathode structures that can reduce voltage and improve current distribution such as figure 1 As shown, the A-A side is as figure 2 As shown, the B-B side is as image 3 As shown, it includes a rectangular parallelepiped cathode carbon block 1 and a long cathode steel rod 3, and the bottom of the rectangular parallelepiped cathode carbon block 1 is provided with two through and parallel steel rod grooves, and each steel rod groove is equipped with a long cathode steel rod 3, The long cathode steel bar has a width of 60mm and a height of 190mm;

[0038] The space between the top surface of each long cathode steel rod 3 and the cuboid cathode carbon block 1 is filled with carbon powder material 2, and the two sides of each long cathode steel rod 3 and the cuboid cathode carbon block 1 are stamped with a side The solid paste 4 is tamped, and the side tamped paste 4 is a cold tamped paste;

[0039] In the carbon powder material 2 in the space b...

Embodiment 2

[0045] The cathode structure of the aluminum electrolytic cell that can reduce the voltage and improve the current distribution is the same as that of Example 1, the difference is that:

[0046] (1) The width of the long cathode steel rod is 70mm and the height is 200mm

[0047] (2) The side tamping paste is hot tamping paste;

[0048] (3) The carbon powder material in the gaps on both sides of the middle of the cuboid cathode carbon block is a mixture of graphite powder and electric calcined anthracite coal powder;

[0049] (4) The carbon powder materials in the gaps on both sides of the middle part of the cuboid cathode carbon block are divided into 3 sections on average, and the weight content of graphite powder in each section of the carbon powder material from both ends to the middle is 40%, 50% and 60% respectively. %;

[0050] (5) The side tamping paste tamped on both sides of the middle part of the cuboid cathode carbon block is divided into 3 sections on average, fr...

Embodiment 3

[0054] The cathode structure of the aluminum electrolytic cell that can reduce the voltage and improve the current distribution is the same as that of Example 1, the difference is that:

[0055] (1) The width of the long cathode steel rod is 80mm and the height is 210mm

[0056] (2) The side tamping paste is hot tamping paste;

[0057] (3) The carbon powder material in the gaps on both sides of the middle of the cuboid cathode carbon block is a mixture of graphite powder, calcined petroleum coke powder and electric calcined anthracite powder, wherein the weight of calcined petroleum coke powder and electric calcined anthracite powder is equal ;

[0058] (4) The side tamping paste tamped on both sides of the middle part of the cuboid cathode carbon block is divided into 4 sections on average, from both ends of the cuboid cathode carbon block to the side tamping paste of each section in the middle, the weight content of graphite powder in the aggregate 30%, 40%, 50% and 60% in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com