Device and method for controlling glue joint curing deformation of dissimilar material

A technology for curing deformation and dissimilar materials, applied in the bonding method of adhesive heating, temperature control without auxiliary power supply, etc., can solve the problems of high cost, reduced adhesive connection strength, inability to eliminate deformation, etc., to achieve high adaptability sex, avoid the effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

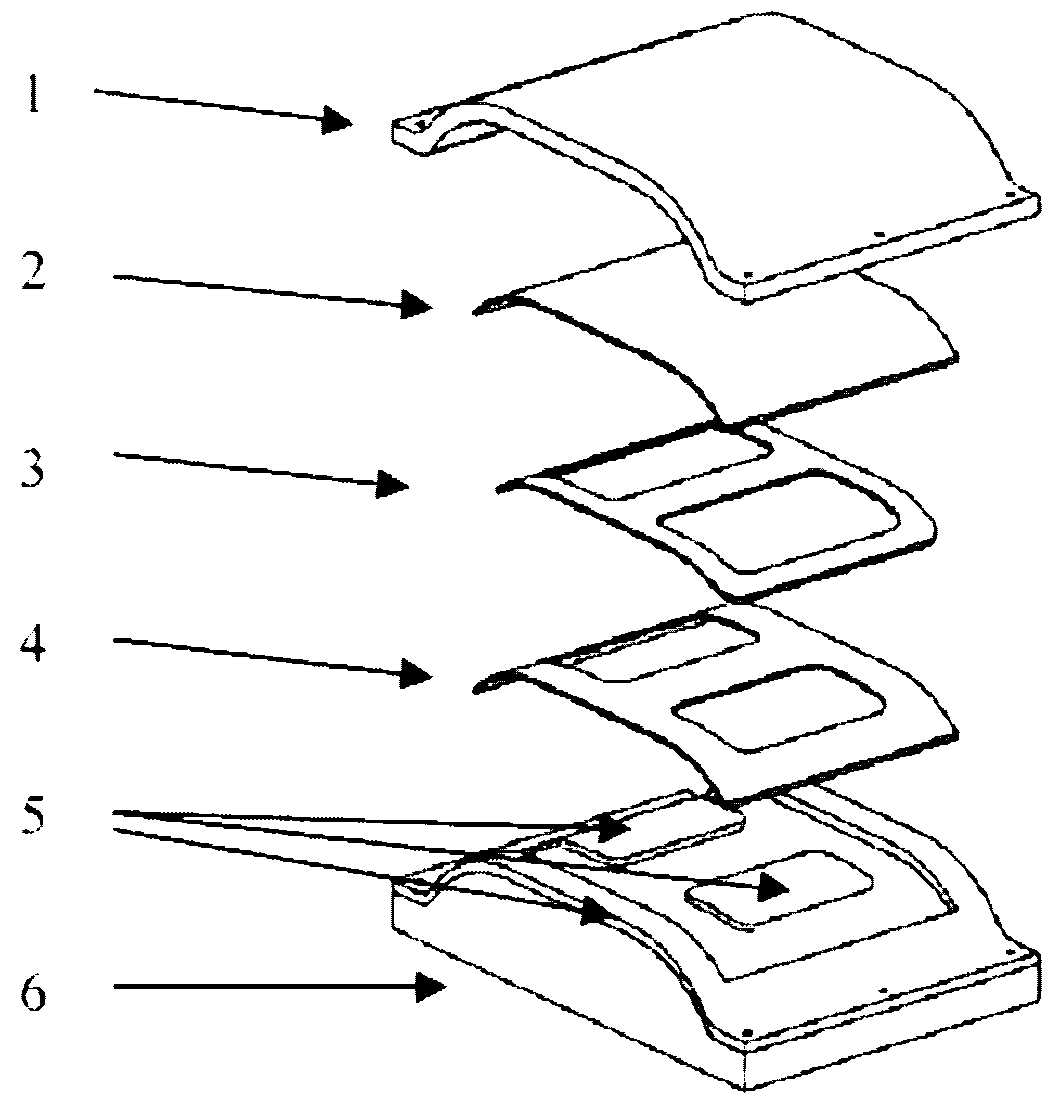

[0028] Such as figure 1 As shown, this embodiment includes: heating and cooling mold 1, high expansion rate parts 2, adhesive layer 3, low expansion rate parts 4, heat insulation accessories 5 and heating mold 6, wherein: heating mold 6, low expansion rate parts 4. The bonding adhesive layer 3 and the heat insulation accessory 5, the high expansion rate part 2 and the heating and cooling mold 1 are stacked in sequence, and the heat insulation accessory 5 and the bonding adhesive layer 3 are located on the same plane; the low expansion rate part 4 is Low carbon steel, its coefficient of thermal expansion is smaller than that of high expansion rate parts 2 aluminum alloy.

[0029] According to the coolant temperature estimation method, the thermal expansion coefficient of aluminum alloy is 23.6e -6 , low carbon steel thermal expansion coefficient 11.3e -6 ~13.5e -6 , the heating temperature is 180°C according to the requirements of the selected adhesive, and the room temperat...

Embodiment 2

[0037] In this embodiment, the low expansion rate part 4 is an aluminum alloy, and its coefficient of thermal expansion is 23.6e -6 , the high expansion rate part 2 is a magnesium alloy, and its thermal expansion coefficient is 27.0e -6 . Low-expansion parts have a lower coefficient of thermal expansion than high-expansion parts.

[0038] The heating temperature is selected at 80°C according to the requirements of the adhesive, the room temperature is 20°C, and the temperature of the corresponding magnesium alloy plate needs to be controlled at about 72°C. Since the temperature difference is not large, the cooling method can be selected as air cooling. Therefore, the described heating and cooling mold 1 is omitted.

[0039] In this embodiment, the cooling temperature step is 1° C., the time step is 1 second, the heating time is 1800 seconds, and the corresponding cooling temperature is 73° C.

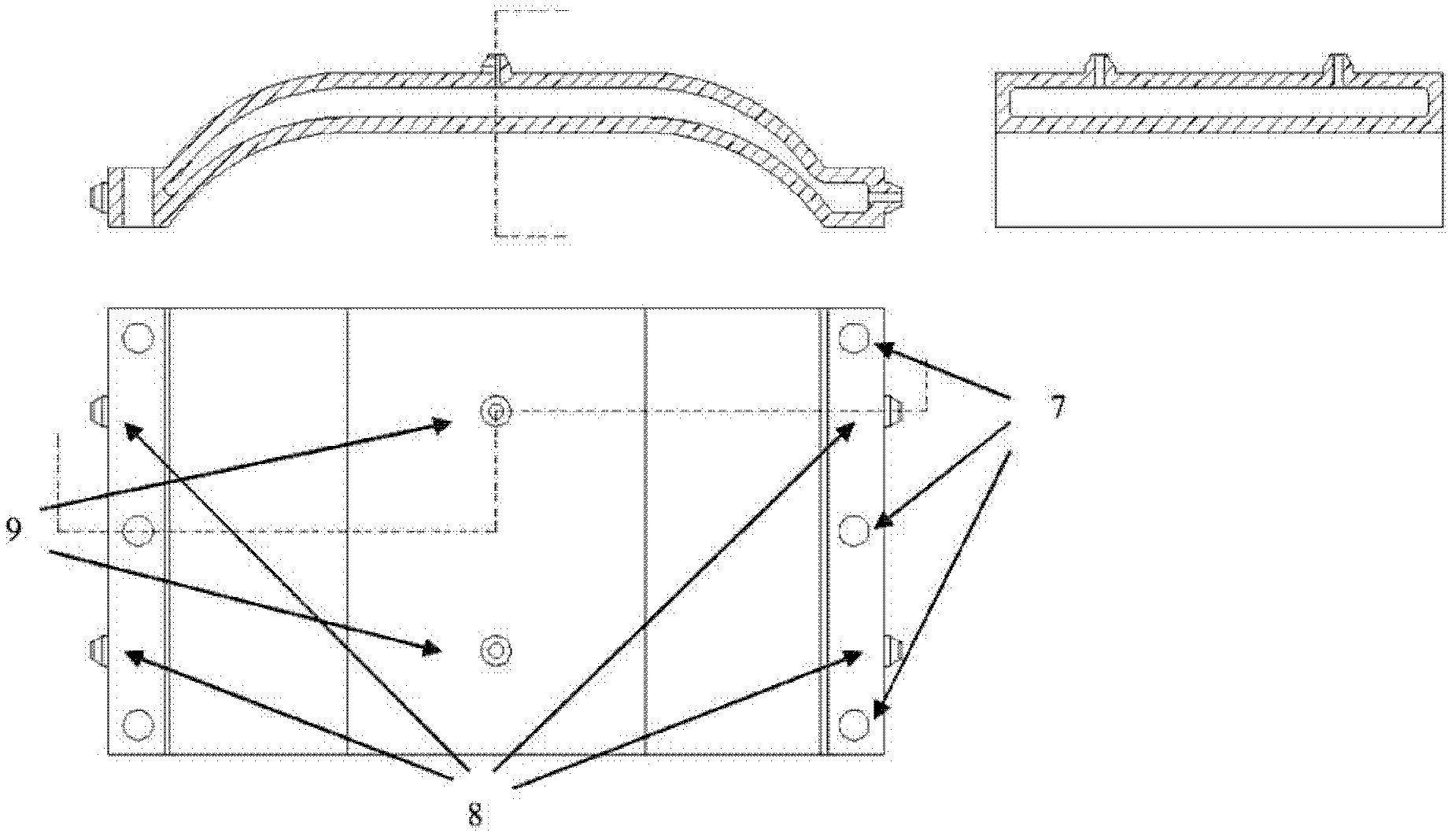

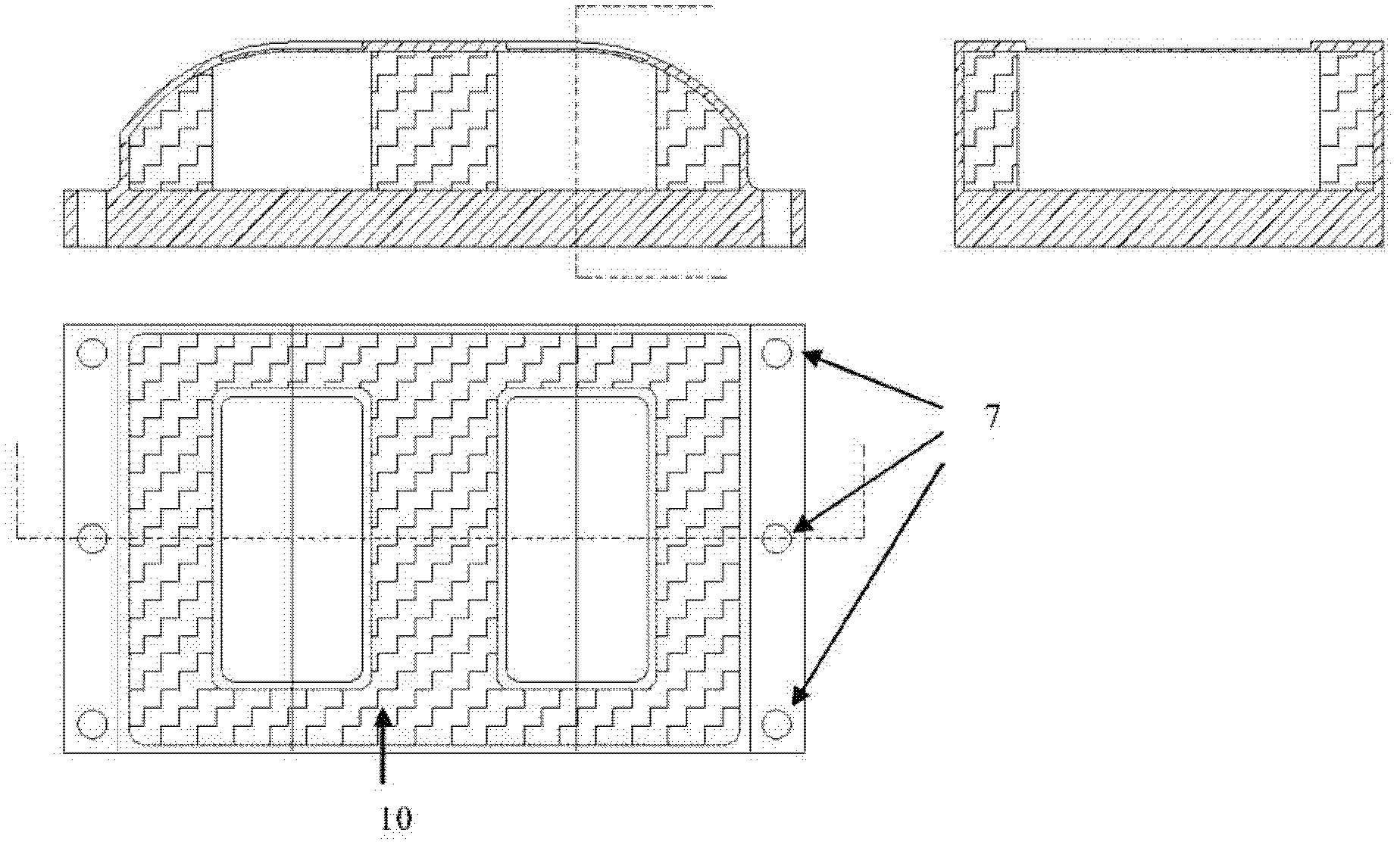

[0040] The concrete form of described heating mold 6 is as follows figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com