Disaccharide compound and separation and purification method thereof

A technology for separation and purification of compounds, which is applied in the field of disaccharide compounds and their separation and purification, can solve the problems of unfavorable compound drug efficacy research and application, high production cost of disaccharide compounds, no compound standard products, etc., to achieve cost reduction and extraction time Short, energy-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

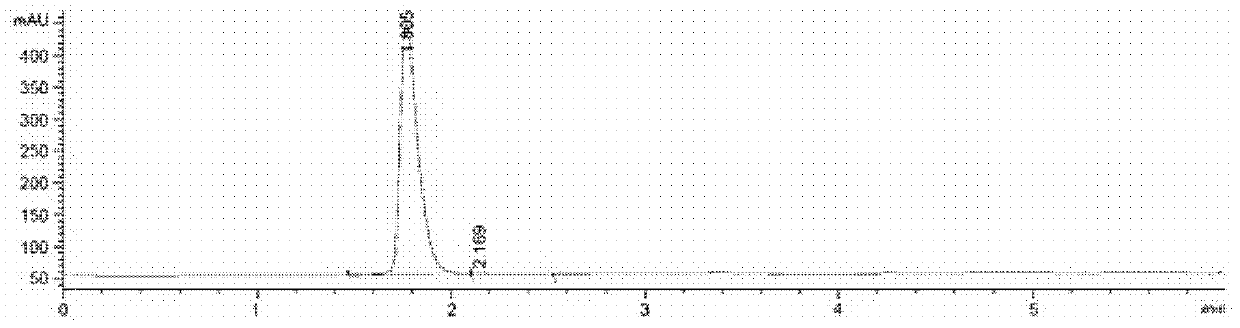

[0027] Embodiment 1 The separation and purification method of formula 1 compound of the present invention

[0028] 10kg of coarse powder of Radix isatidis, soaked in 65% ethanol for 1 hour, and refluxed for 3 times, 1 hour each time. The extracts were combined, ethanol was recovered under reduced pressure until there was no alcohol smell, vacuum-dried at 50° C., and pulverized to obtain 1390 g of dry extract powder of the crude extract, with a yield of 13.9%. Take 500g of crude extract dry extract powder and extract with 95% ethanol under reflux for 3 times, each time for 1 hour, filter, combine the extracts, recover ethanol under reduced pressure until there is no alcohol smell, dry in vacuum at 50°C, and crush to obtain Radix Radix dry infusion Paste powder 140g, the yield is 3.9%.

[0029] The dry extract powder of Radix isatidis was separated by dry column chromatography on a silica gel column, eluted with dichloromethane-methanol (100:0-1:1) gradient, checked by thin-lay...

Embodiment 2

[0033] Embodiment 2 The separation and purification method of the compound of formula 1 of the present invention

[0034] 10kg of coarse powder of Radix isatidis, soaked in 65% ethanol for 1 hour, and refluxed for 3 times, 1 hour each time. The extracts were combined, ethanol was recovered under reduced pressure until there was no alcohol smell, vacuum-dried at 50° C., and pulverized to obtain 1390 g of dry extract powder of the crude extract, with a yield of 13.9%. Take 500g of crude extract dry extract powder and extract with 80% ethanol under reflux for 3 times, each time for 1 hour, filter, combine the extracts, recover ethanol under reduced pressure until there is no alcohol smell, vacuum dry at 50°C, and pulverize to obtain Radix Radix dry infusion Paste powder 172g, the yield is 4.8%.

[0035] The dry extract powder of Radix isatidis was separated by dry column chromatography on a silica gel column, eluted with dichloromethane-methanol (100:0-1:1) gradient, checked by ...

Embodiment 3

[0036] Embodiment 3 The separation and purification method of the compound of formula 1 of the present invention

[0037]10kg of coarse powder of Radix isatidis, soaked in 50% ethanol for 1 hour, and refluxed for 3 times, 1 hour each time. The extracts were combined, the ethanol was recovered under reduced pressure until there was no alcohol smell, vacuum-dried at 50° C., and pulverized to obtain 1560 g of dry extract powder of the crude extract, with a yield of 15.6%. Take 500g of crude extract dry extract powder and extract with 95% ethanol under reflux for 3 times, each time for 1 hour, filter, combine the extracts, recover ethanol under reduced pressure until there is no alcohol smell, vacuum dry at 50°C, and crush to obtain Radix Radix dry infusion Paste powder 168g, the yield is 5.2%.

[0038] The dry extract powder of Radix isatidis was separated by dry column chromatography on a silica gel column, eluted with dichloromethane-methanol (100:0-1:1) gradient, checked by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com