Quantitative and order feeding machine

A technology of feeder and suction pipe, which is applied in the direction of tea processing before extraction, can solve the problems of failure to realize tea paving and the inability to continuously discharge materials from the discharge port, so as to ensure the quality of paving, improve production efficiency, and be simple and convenient. effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

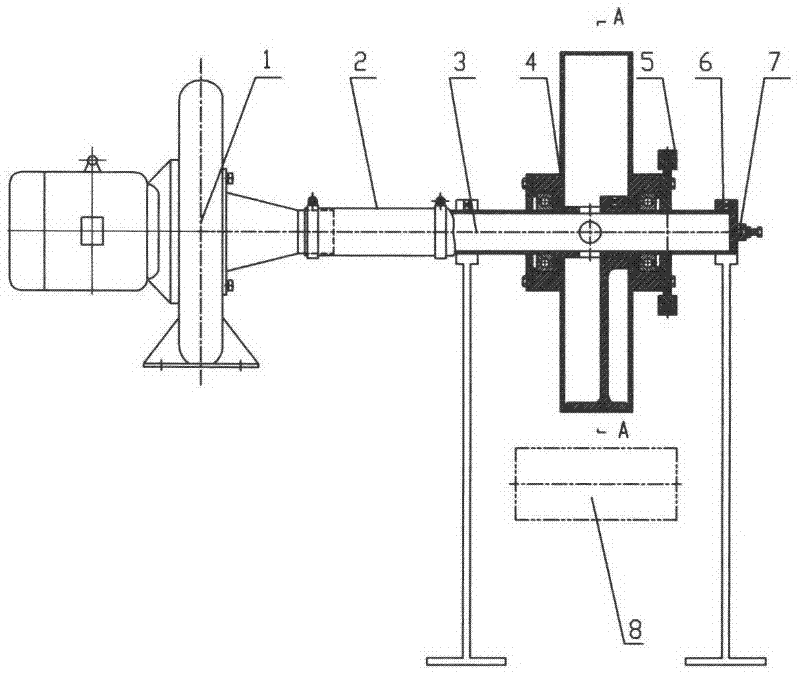

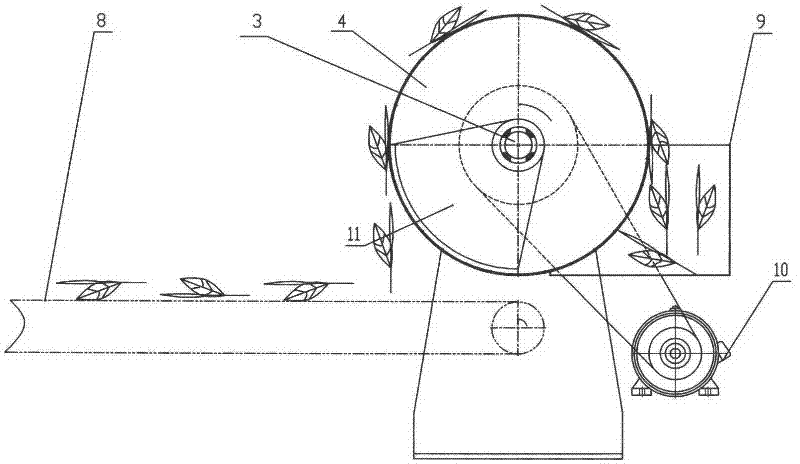

[0013] The quantitative and orderly feeding machine of the present embodiment is as figure 1 and figure 2 As shown, the rotatable suction roller 4 is a hollow wheel-shaped member supported centrally on the horizontal suction pipe shaft 3, connected with the speed regulating motor 10 through the belt drive mechanism 5, and located above one end of the conveyor belt 8. Both ends of the suction pipe shaft 3 are fixedly supported on the bracket 6, one end of which communicates with the air inlet of the fan 1 as a negative pressure generating device through the connecting pipe 2, and the middle part has a suction hole communicated with the hollow part of the suction roller 4 . Suction holes arranged at intervals on the rim circumference of the suction roller 4 according to a predetermined rule, the lower part of one side corresponds to the fourth quadrant, and a hopper 9 for tea can be absorbed by the suction holes is placed outside, and the lower part of the other side correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com