Net shed for breeding entomoplily cross pollinated cultivate plants

A technology of insect-borne different flowers and crops, applied in the field of net sheds, can solve the problems of large net sheds, poor wind resistance, and hard work of personnel, achieve high crop seed setting rate, save artificial pollination, and bee release is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

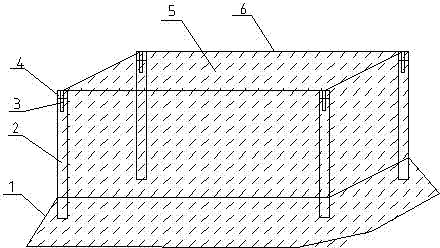

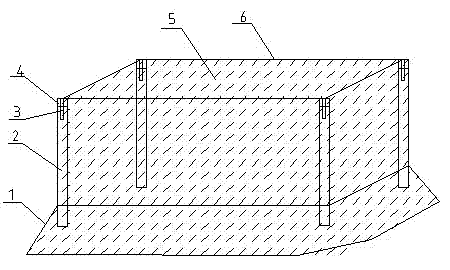

[0007] from figure 1 As can be seen from the shown structural representation of the present invention, the present invention is made up of two parts of support and net body, and support is made up of support 2, rubber pad 4, " "[" type 8# iron wire 6, and support 2 is bamboo pole or plank. There are 4 pillars of the small net shed, and each pillar 2 is a straight bamboo pole with a height of 1.4-1.6 meters and a diameter of 0.02-0.09 meters, or a straight plank with a height of 1.4-1.6 meters and a cross-section of 0.02-0.03 meters × 0.05-0.07 meters. Hole 3 is vertically punched in the cross-section of the upper end of pillar 2. The thickness of hole 3 is to facilitate the insertion of two 8# iron wires, and the depth is 0.08-0.12 meters. The upper end of the pillar 2 is cushioned with a rubber pad 4, the specification of the rubber pad 4 is matched with the cross section of the upper end of the pillar 2, the thickness is 0.5-2.0 mm, the center is punched, and the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com