Transmission mechanism of plastic bottle blowing machine

A technology of transmission mechanism and bottle blowing machine, which is applied to transmission devices, mechanical equipment, hollow objects, etc., can solve the problems of high cost, cost extrusion, and increase of the gap between left and right swings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

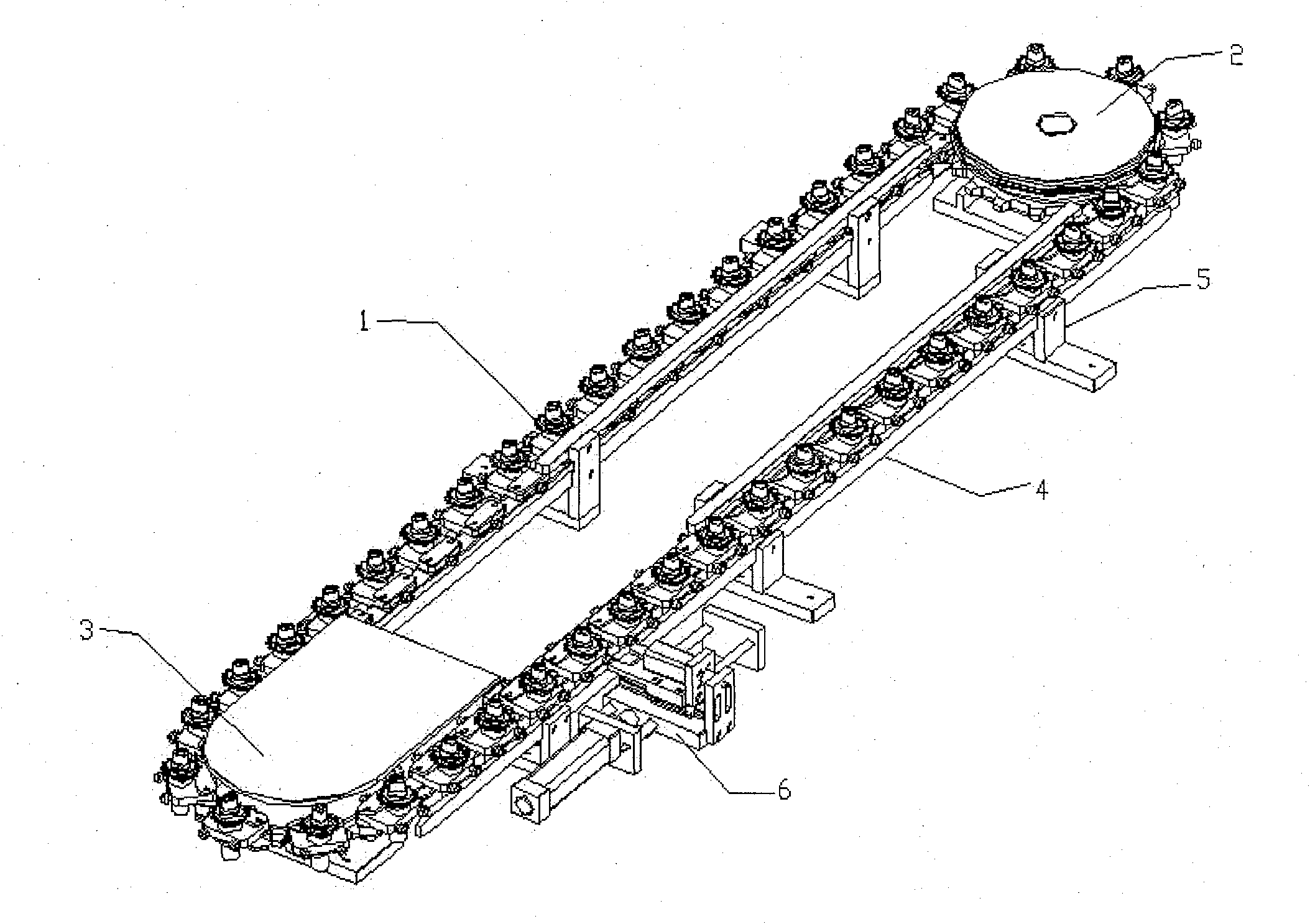

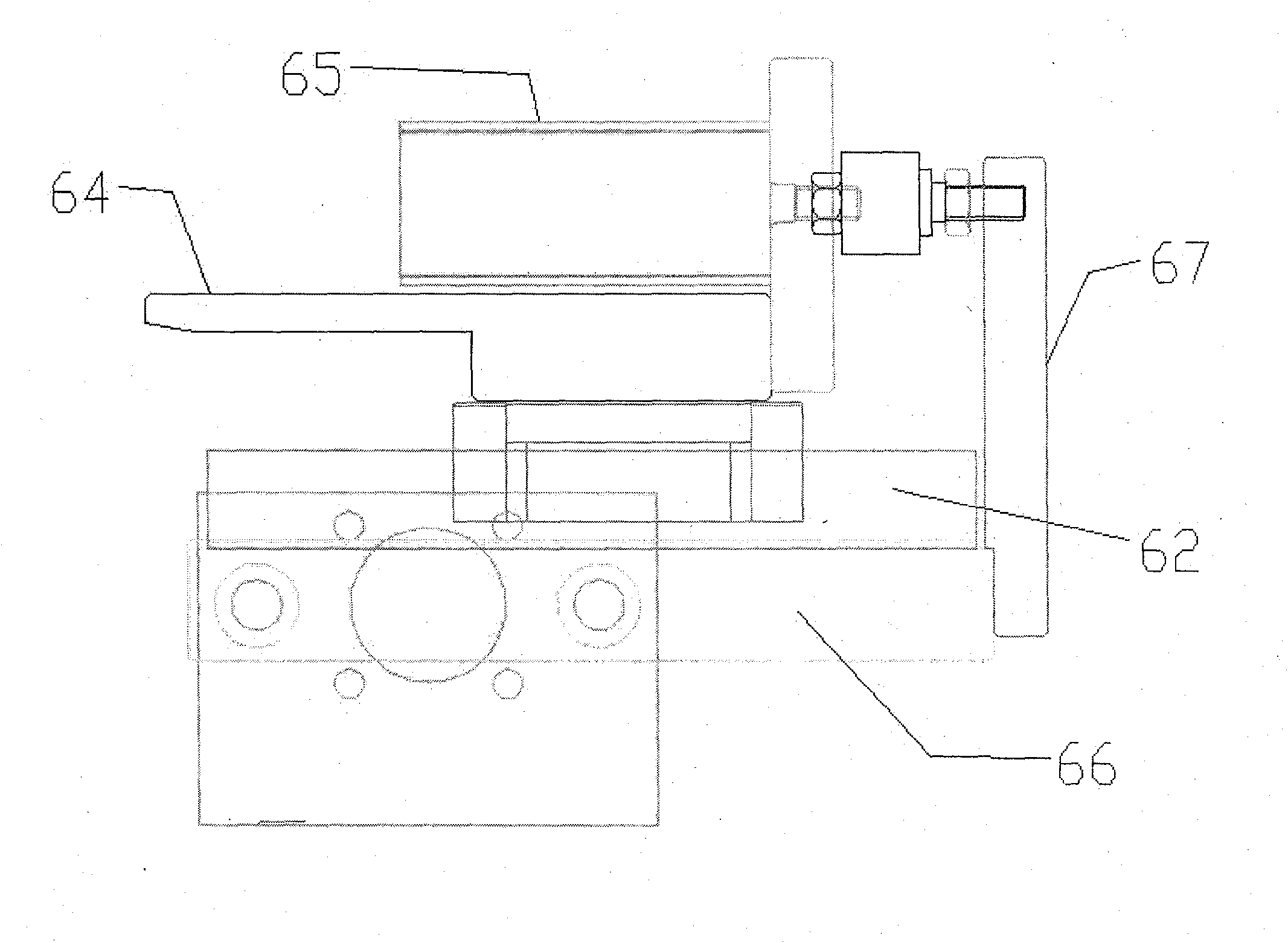

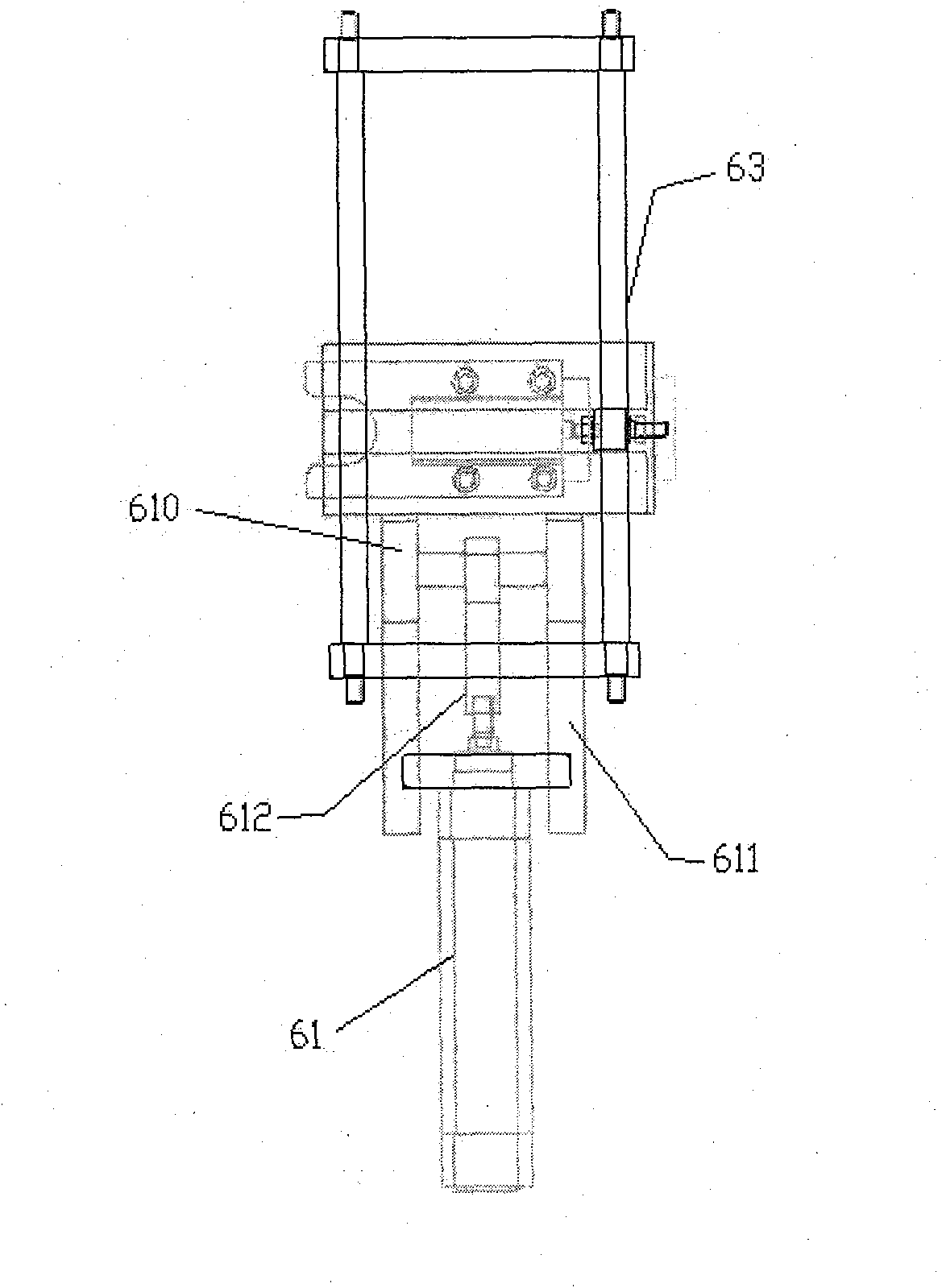

[0015] as follows figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention is a transmission mechanism of a plastic bottle blowing machine, which mainly includes a chain assembly 1, on which a front revolving wheel 2, a rear revolving wheel 3 and a guide rail 4 are installed, and on the guide rail 4 A guide rail bracket 5 and a stepping mechanism are installed. The chain assembly 1 is composed of a self-made chain block, a heating seat and a chain, and then it is mounted on the guide rail 4 to allow it to slide freely on the guide rail 4. Composed of more than two sprockets, it plays the role of rotation and support. The stepping mechanism mainly includes a stepping cylinder 61 and a positioning cylinder 65. The positioning cylinder 65 is installed on the linear guide pair 62. The linear guide pair 62 and the positioning fork 64 are in turn Installed on the sliding seat 66, the sliding seat 66 is worn on the guide rod 63, so that the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com