Synthesis method of sugar via extracellular enzyme catalysis

A synthesis method and technology of catalyzing sugar, applied in the direction of fermentation, etc., can solve the problems of complex structure reactor and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

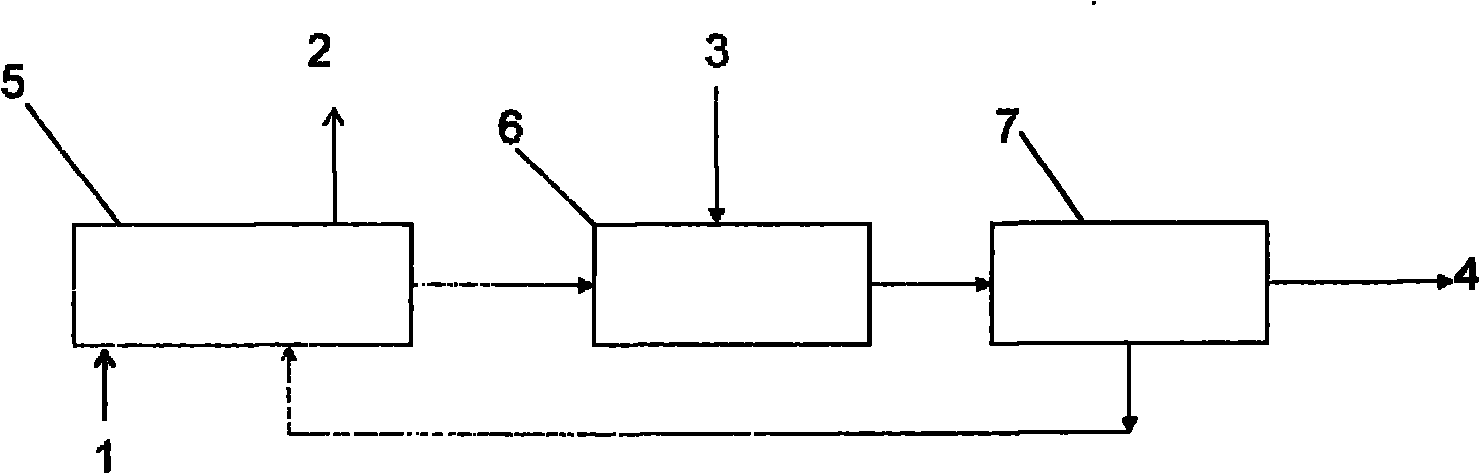

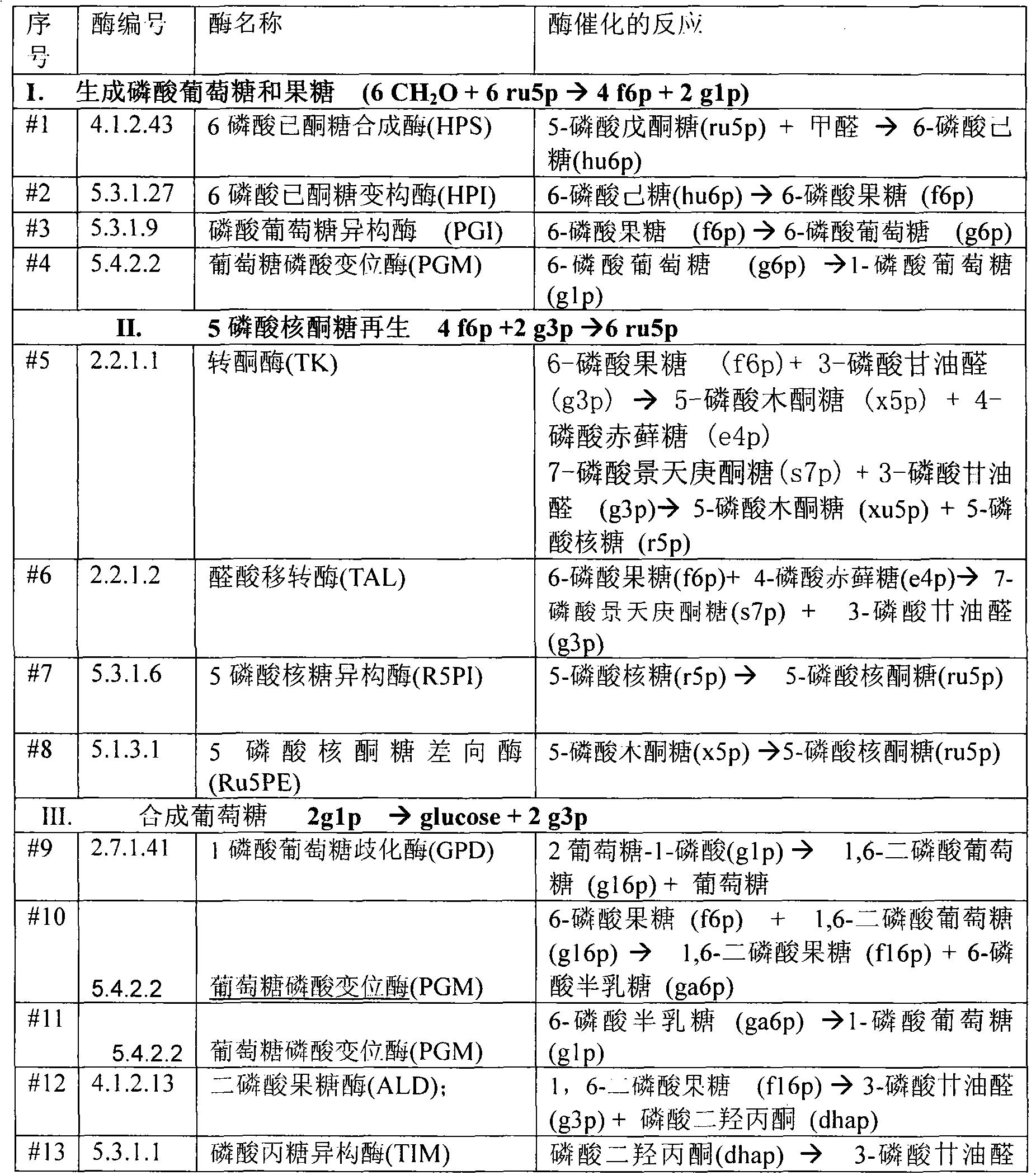

[0045] Embodiment 1, formaldehyde is made raw material, produces glucose: in continuous flow reactor, water is made solvent, adds the required enzyme of reaction, and table 1 has listed these enzymes and the reaction that they catalyze, adds intermediate product 6 phosphate glucose in addition, Keeping the temperature of the reactor at 25°C, the reactant formaldehyde is continuously added to the reflux liquid and flows into the reactor, and the solution flows out continuously from the outlet of the reactor. After separating the glucose and removing part of the water, it flows back into the reactor. The concentration of formaldehyde in the solution at the inlet of the reactor is 30%, and the concentration of glucose at the outlet of the reactor is about 10%. Since no by-products can be detected, the formaldehyde is nearly 100% converted into glucose. In this embodiment, chemical catalysis can also be added, carbon dioxide is hydrogenated to formaldehyde, and the raw materials ar...

Embodiment 2

[0049] Embodiment 2, hydrogen and carbon dioxide are made raw materials, and product is starch: in continuous flow reactor, add water and do solvent, add the required enzyme of reaction, table 2 has listed these enzymes and the reaction that they catalyze, and enzyme is fixed at high On the molecular carrier, the intermediate product 6-phosphate glucose, NAD + , ATP, and maltotriose can also be added as a primer for synthesizing starch. Keep the temperature of the reactor at 25°C, continuously feed carbon dioxide and hydrogen into the reactor, and the solution will flow out continuously from the outlet of the reactor. After separating glucose and removing part of the water , backflow into the reactor. The starch concentration at the outlet of the reactor was about 8%, and hydrogen and carbon dioxide were nearly 100% converted into starch because no by-products were detected.

[0050] Table 2: Reactions and enzymes used in artificial photosynthesis dark reaction pathway driven...

Embodiment 3

[0053] Example 3, hydrogen and coal-fired power plant exhaust gas are used as raw materials, and the product is starch: a carbon dioxide fixation reactor, a sugar synthesis reactor and a separator are used to form a system, and water is used as a solvent. When starting the reactor, add synthetic starch to the reactor aqueous solution. All the enzymes required for the sugar reaction, Table 3 shows these enzymes and the reactions they catalyze, and the intermediate product 6-phosphate glucose, NAD + , ATP, keep the reactor temperature at 25°C, feed gas containing carbon dioxide into the carbon dioxide fixation reactor, such as waste gas containing 10% carbon dioxide from a coal-fired power plant, feed high-purity hydrogen into the sugar synthesis reactor, and react The liquid stays in the carbon dioxide fixation reactor for a period of time, carries out the carbon dioxide fixation reaction under the enzyme catalysis, and then discharges into the sugar synthesis reactor, stays for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com