Sludge-dewatering compound conditioning agent and application method thereof

A technology of sludge dewatering and application method, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc. Dehydration, water can not be released to the maximum extent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A composite conditioner for sludge dehydration, comprising a weight ratio of 18:23 Fenton's reagent and a skeleton construct, wherein the Fenton's reagent contains H 2 SO 4 / FeSO 4 / H 2 o 2 Fenton system, the skeleton structure is lime powder.

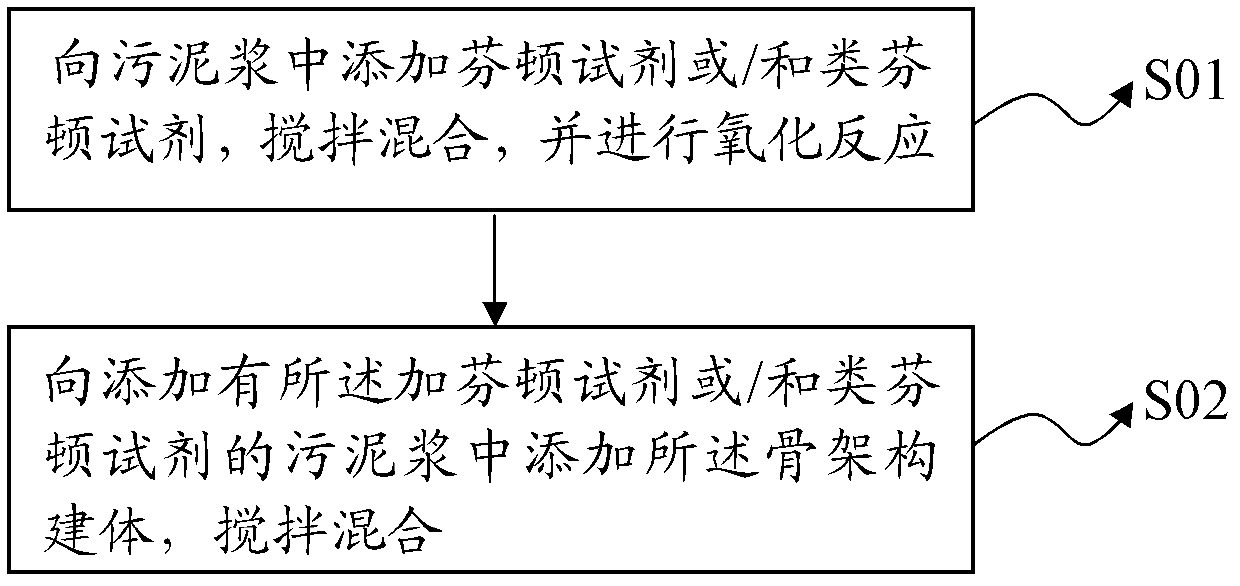

[0072] The application method of the sludge dehydration composite conditioner is as follows:

[0073] Step S11: Take the mixed sludge with a water content of 99.0% from the urban sewage treatment plant, add H to the sludge 2 SO 4 / FeSO 4 / H 2 o 2 Fenton's reagent, the step of adding this Fenton's reagent is:

[0074] Step S111: Adding 50% H to the 96.0% thickened sludge 2 SO 4 Solution, adjust sludge pH=5;

[0075] Step S112: Adding FeSO to the sludge with pH=5 4 Aqueous solution of FeSO 4 The amount added is 3.0wt% of the sludge dry basis, and stirred for 2 minutes, so that FeSO 4 Mix well with sludge;

[0076]Step S113: Add FeSO 4 Add H to the sludge 2 o 2 , H 2 o 2 The dosage is 12.5wt% of the sludge dry ...

Embodiment 2

[0080] A composite conditioner for sludge dehydration, comprising a weight ratio of 17:23 Fenton's reagent and a skeleton construct, wherein the Fenton's reagent contains H 2 SO 4 / FeSO 4 / H 2 o 2 In the Fenton system, the skeleton structure is a mixed powder of lime and red mud with a weight ratio of 1:1.

[0081] The application method of this sludge dehydration composite conditioner is referring to step S11 to step S12 in embodiment 1, and the difference is that the moisture content of the concentrated sludge is 95.9%; H 2 SO 4 The concentration of the solution is 98%, and it adjusts the pH of the sludge to 3.5; after adding lime and red mud mixed powder, stir and mix until uniform.

[0082] After the pretreated sludge in Example 2 is dewatered by plate-and-frame filter press, the specific resistance reduction rate of the dehydrated sludge is 89%, and the CST reduction rate is 61%.

Embodiment 3

[0084] A composite conditioner for sludge dehydration, comprising a weight ratio of 17:23 Fenton's reagent and a skeleton construct, wherein the Fenton's reagent contains H 2 SO 4 / FeSO 4 / H 2 o 2 In the Fenton system, the framework structure is a mixed powder of lime and phosphogypsum with a weight ratio of 1:1.

[0085] The application method of this sludge dehydration composite conditioner is referring to step S11 to step S12 in embodiment 1, and the difference is that the moisture content of the concentrated sludge is 95.9%; H 2 SO 4 The concentration of the solution is 98%, and the pH of the sludge is adjusted to be 5; the mixed powder of lime and phosphogypsum is added and stirred until uniform.

[0086] After the sludge pretreated in Example 3 is dewatered by plate-and-frame filter press, the specific resistance reduction rate of the dehydrated sludge is 90%, and the CST reduction rate is 63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com