Sludge dewatering method

A sludge dewatering and sludge technology, applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problem of low dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

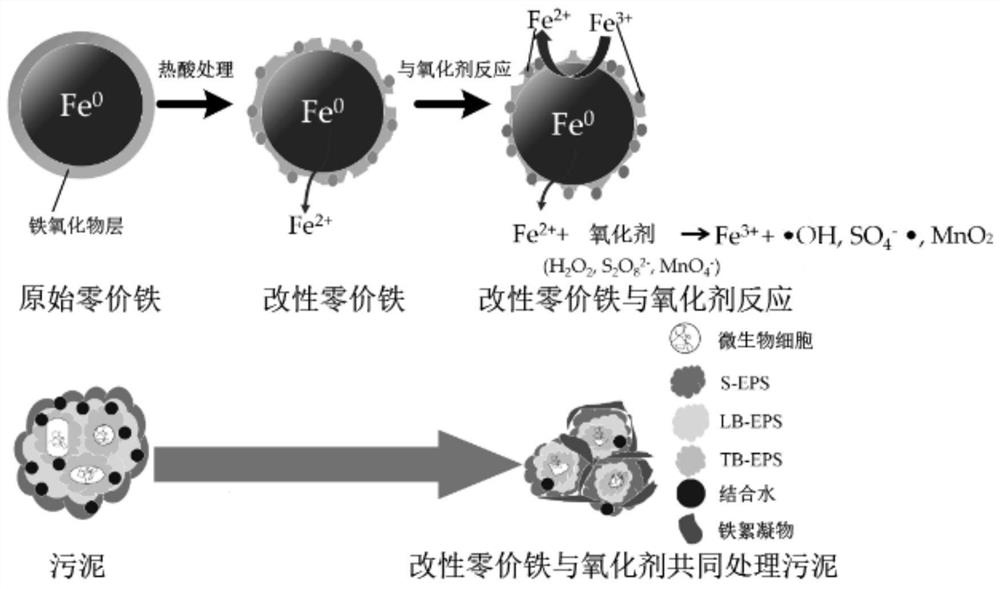

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a sludge dehydration method, the steps are as follows:

[0047] (11) Mix the nano-raw zero-coastal iron with 0.05 m of dilute sulfuric acid solution was mixed at a solid-liquid ratio of 1: 9, and treated at 60 ° C for 10 min. After filtering, the obtained solid was vacuum freeze drying 24h at -60 ° C. , Get the modified zero-valence iron;

[0048] (12) The moisture content of 96% was added to the concentrated sludge of 1 mg / g of sludge, and 0.4 mg / g sludge dry weight, mixed, mixed, stirred at 100 rpm for 5 min;

[0049] (13) 10 min was filled with 5 MPa ultra-high pressure, resulting in a water content of 45%.

Embodiment 2

[0051] This embodiment provides a sludge dehydration method, the steps are as follows:

[0052] (21) Mix the nano-raw zero-coil iron and 0.05 m dilute sulfuric acid solution was mixed according to the solid-liquid ratio of 1: 9, and treated at 60 ° C for 10 min. After filtration, the obtained solid was vacuum freeze drying 24h at -60 ° C. , Get the modified zero-valence iron;

[0053] (22) EtOAc EtOAc EtOAc EtOAc (EtOAc)

[0054] (23) 10min was filled with 4 MPa ultra-high pressure, resulting in a water content of 47%.

Embodiment 3

[0056] This embodiment provides a sludge dehydration method, the steps are as follows:

[0057] (31) Mix the nano-raw zizici iron and 0.05 m dilute sulfuric acid solution was mixed according to the solid - liquid ratio of 1: 9, and treated at 60 ° C for 10 min, filtered, and the obtained solid was vacuum freeze drying 24h at -60 ° C. , Get the modified zero-valence iron;

[0058] (32) EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc.

[0059] (33) was filled with 5 MPa ultra-high pressure filtration, resulting in a water content of 42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com