Device and method for treating ammonia nitrogen wastewater by using dioxygen biological filler

A technology of ammonia nitrogen wastewater and biological filler, applied in the field of environmental engineering, can solve the problems of high ammonia nitrogen hazard, slow value-added speed of nitrifying bacteria, low nitrification speed, etc., and achieve the effect of automatic reflux without pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

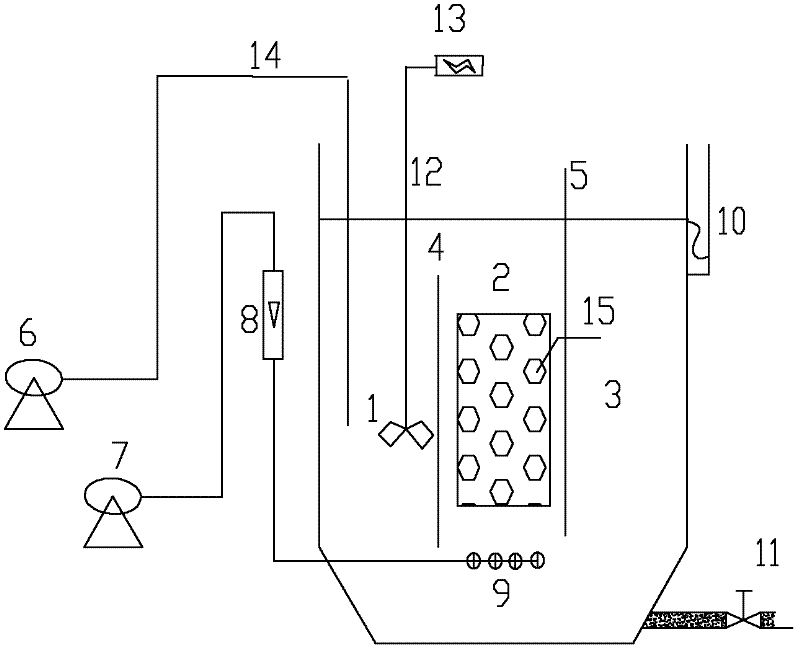

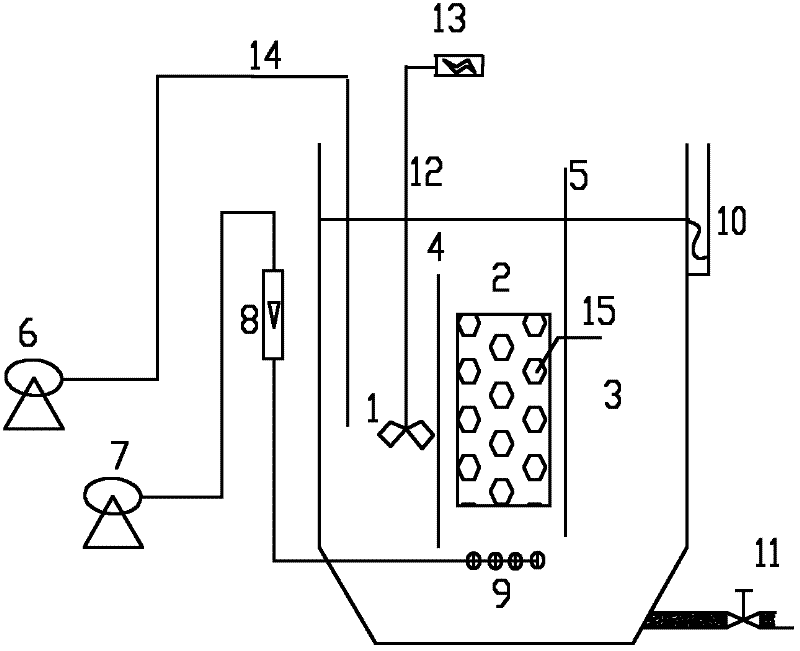

[0027] A device for treating ammonia nitrogen wastewater by using hydrogen peroxide biological filler, its structure is as follows figure 1 As shown, it is composed of a reactor, a water inlet pipe 14, a water outlet 10 and a mud discharge port 11; the reactor is divided into an anoxic zone 1, an aerobic zone 2 and a sedimentation zone 3 by two adjustable control panels 4 and 5, The bottoms of the three zones are connected; the adjustable control plate 4 controls the residence time of the wastewater in the anoxic zone 1 by adjusting the size of the circulation gap, and reduces backflow while ensuring the denitrification rate; the inlet of the water inlet pipe 14 is located in the anoxic zone 1, one end of the water inlet pipe 14 is connected with the water inlet pump 6; the middle bottom of the anoxic zone 1 is equipped with a mixer 12, and one end of the mixer 12 is connected with a pressure regulator 13, and the function of the pressure regulator 13 is to change the mixing fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com