Method for processing diaspore ore to produce alumina

A technology of aluminum oxide and aluminum hydroxide, applied in the direction of aluminum oxide/aluminum hydroxide, energy input, etc., can solve the problem of low lye circulation efficiency, etc., and achieve the effect of shortening seed decomposition time, improving efficiency and easy decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

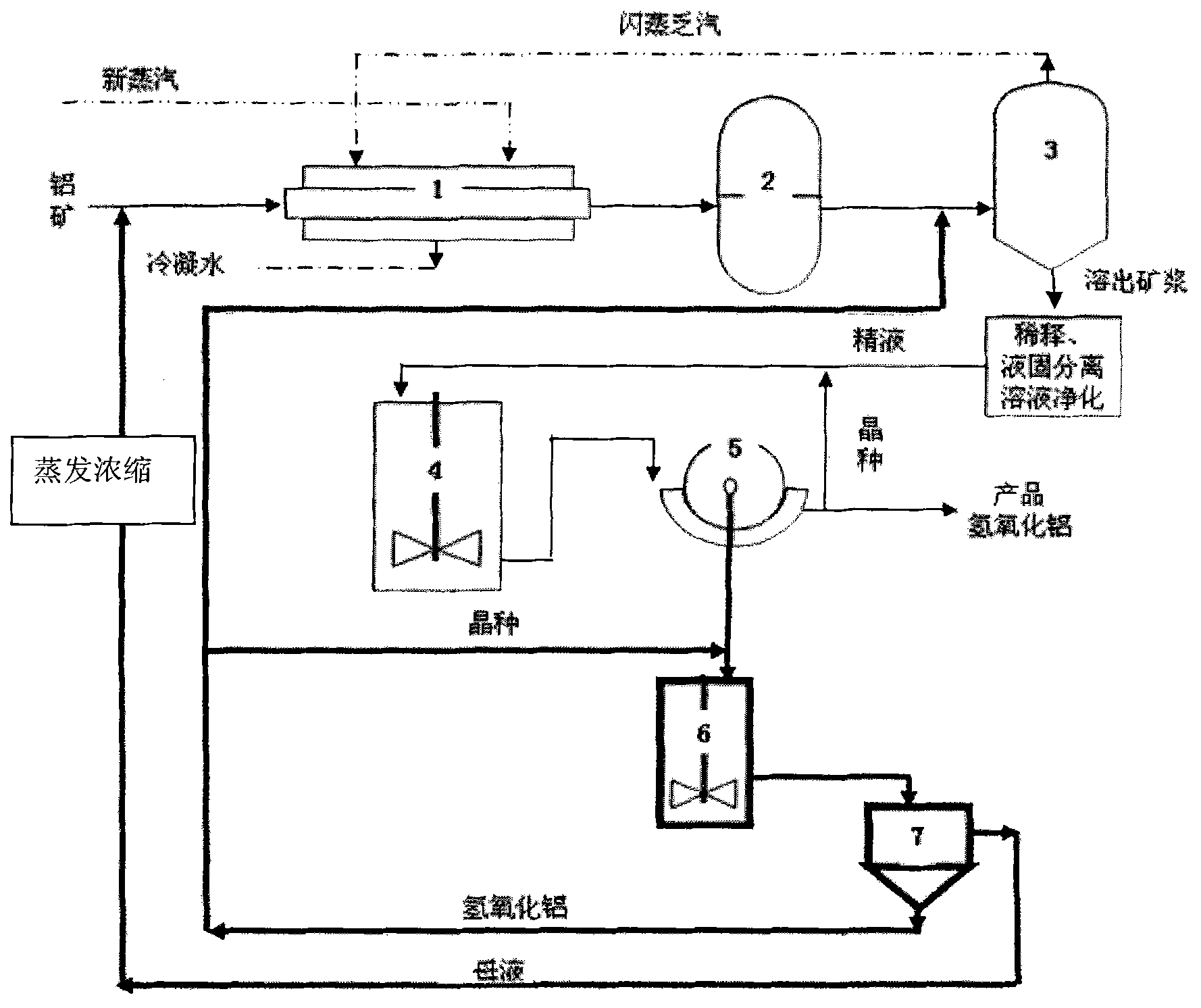

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] As shown in the figure, a method for processing diaspore ore to produce alumina, the decomposed slurry enters the aluminum hydroxide separation device 5 for separation, and the obtained mother liquor is sent to the deep decomposition tank 6 and added suitable Seed crystals, lowering the decomposition temperature and other conditions for deep decomposition, the aluminum hydroxide part obtained from deep decomposition is recycled as deep decomposition seed crystals, and the rest is sent to the end of the dissolution system for redissolution, and the mother liquor after deep decomposition is evaporated and concentrated and then returned to the front-end ingredients; The seed decomposition is carried out in the decomposition tank 4, and the aluminum hydroxide separation equipment 5 separates the product aluminum hydroxide part as the seed crystal for seed decomposition, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com