Double-head cylinder wheel pair press fit machine with following trolley

A technology of pressing machine and trolley, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of feeding and discharging without supporting body, increasing the cost of using the manufacturer, affecting the efficiency of pressing, and simplifying the wheelset. Clamping, interference avoidance, full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

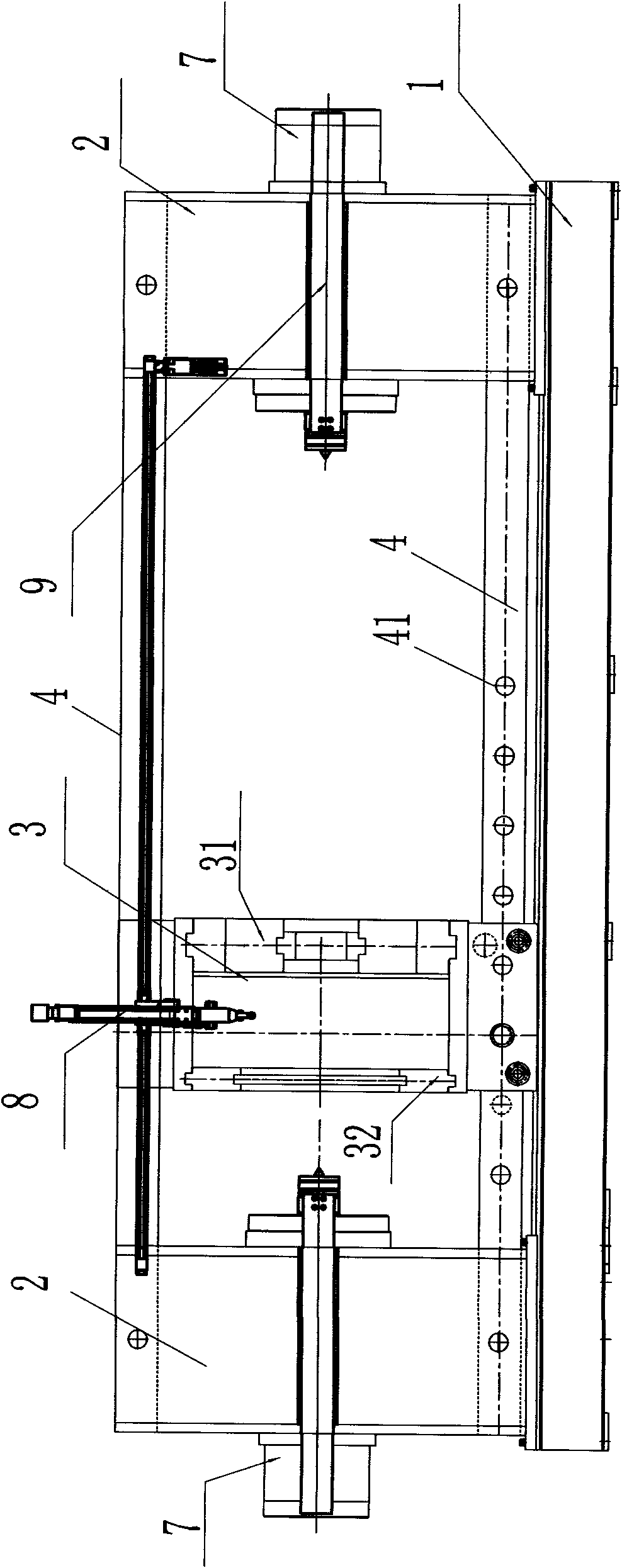

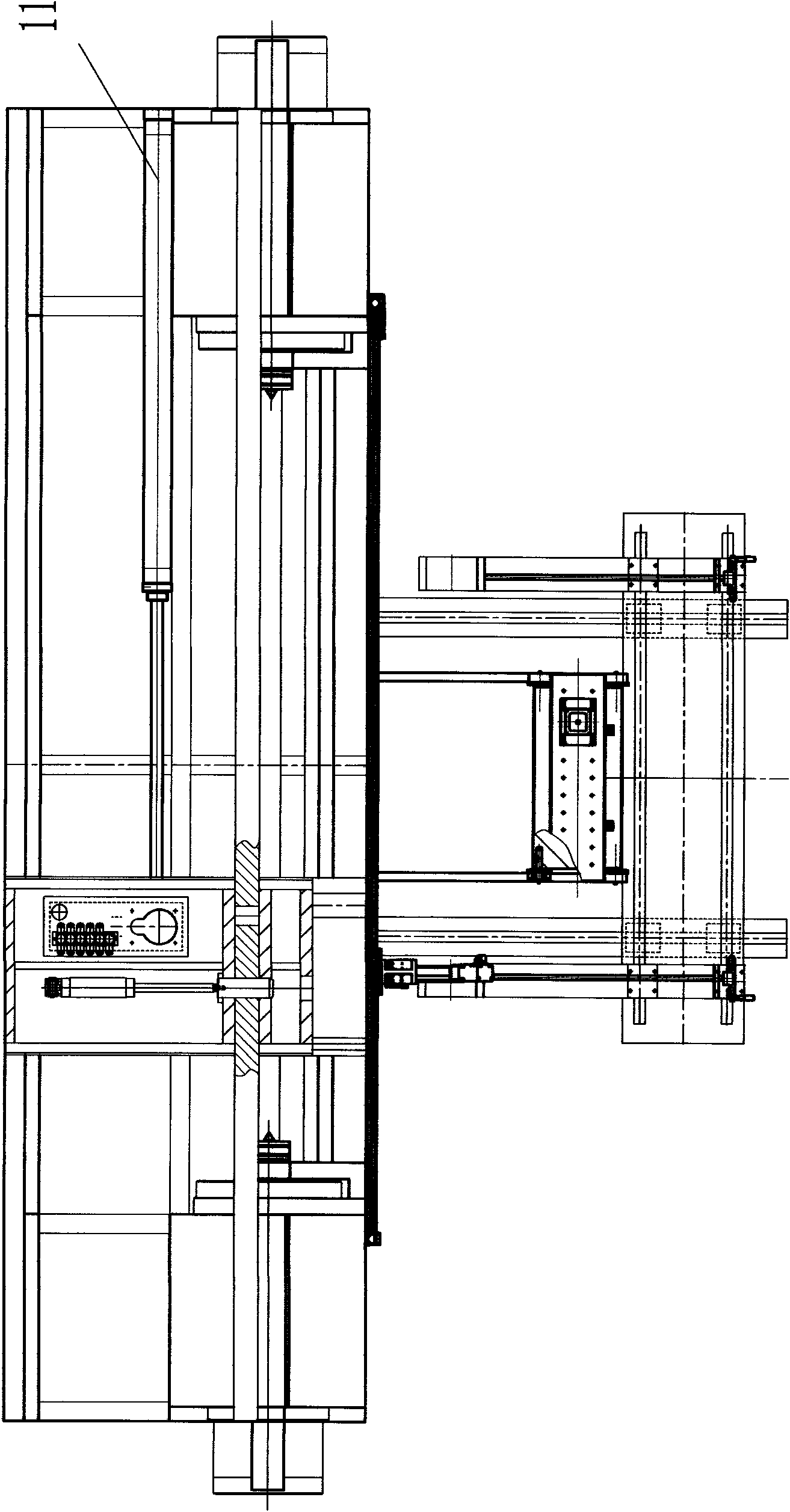

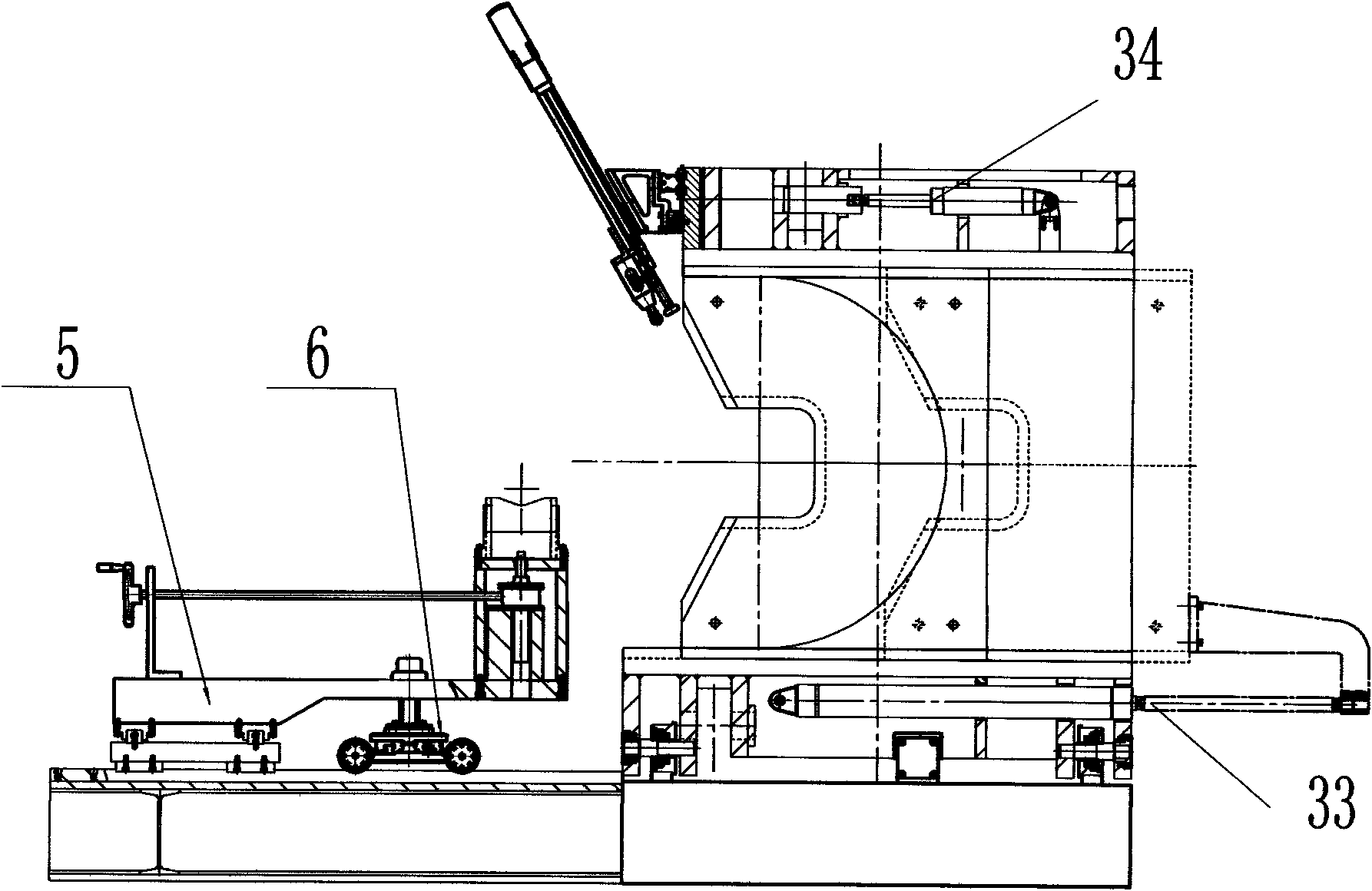

[0015] Such as Figure 1 to Figure 4 As shown, the present invention discloses a double-head oil cylinder wheel pair press-fitting machine with a follower trolley, including a base 1, a fixed beam device 2, a movable beam device 3, a pillar 4, a supporting trolley 5, a follower trolley 6, a main press Oil cylinder 7, hydraulic system, electric control system, detection device 8, described main pressure oil cylinder 7 front is equipped with thimble device, described main oil cylinder device is provided with guiding mechanism 9, described two fixed beam devices 3 fix respectively On the left and right ends of the base 1, and connected up and down with two transverse pillars 4 to form a stressed frame, the two fixed beam devices are equipped with a main pressure oil cylinder 7, and the movable beam device 3 is equipped with Two inserting plates 31 and 32, the movable bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com