Numerical-control plasma power source with multiple plasma cutting torches

A plasma and cutting torch technology, applied in the field of ion power supply, can solve the problems of incomplete arc starting on foot, affecting the accuracy of cutting products, and low cutting accuracy, and achieve the effects of saving resources, light weight, and high cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

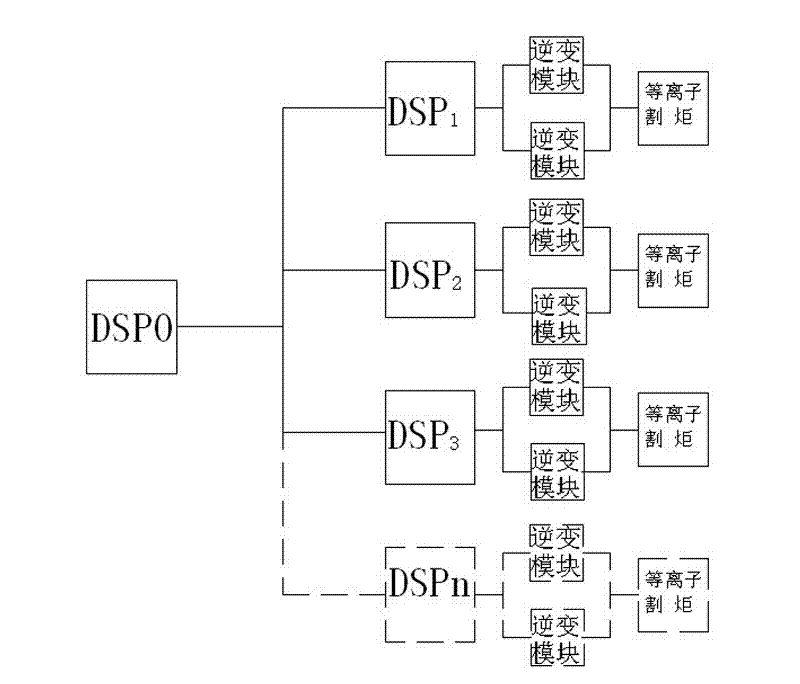

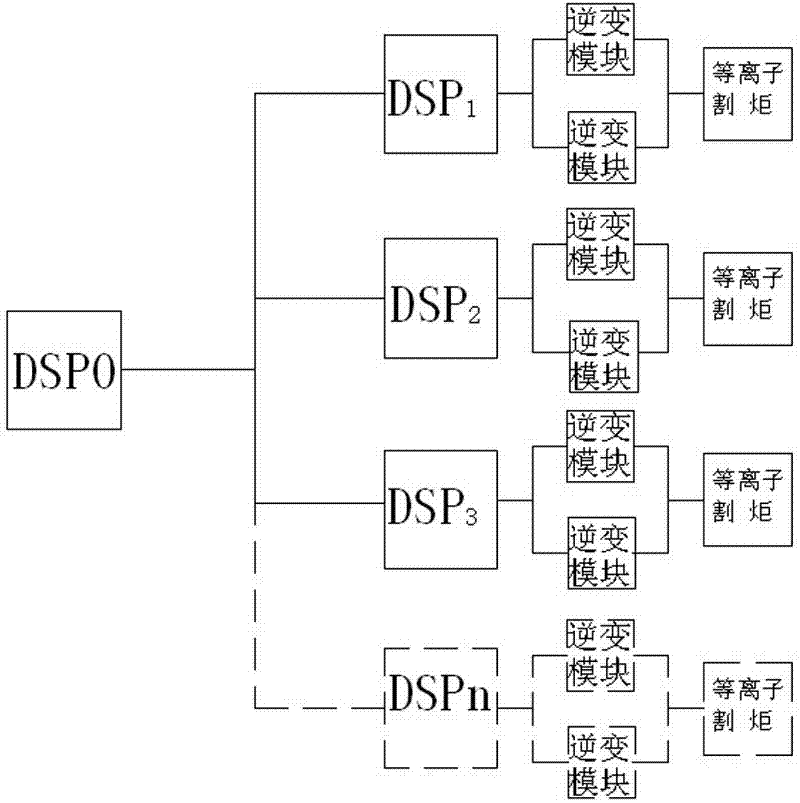

[0007] Below in conjunction with accompanying drawing, the numerical control plasma power source of multiple plasma cutting torches of the present invention is described in further detail:

[0008] Using DSP as the control chip of the power supply makes the inverter power completely digital. As can be seen from the accompanying drawings, the present invention includes a total DSP digital signal controller, said total DSP digital signal controller is connected with a plurality of sub-DSP signal controller input terminals through control lines, and each sub-DSP signal controller is connected by at least two Each inverter module is connected with a plasma cutting torch, and each inverter module is connected with CAN bus (controller area network). Each inverter module collects the voltage and current at the output end of its own inverter bridge, and actively transmits its own voltage, current and power to other inverter modules through the CAN bus. Since the transmission speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com