Lining of rod mill

A rod mill and lining technology, applied in the field of rod mill components, can solve the problems of large weight of grinding rod bundles, low production efficiency, waste of raw materials, etc., so as to prolong the maintenance period, improve production efficiency, and achieve good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing.

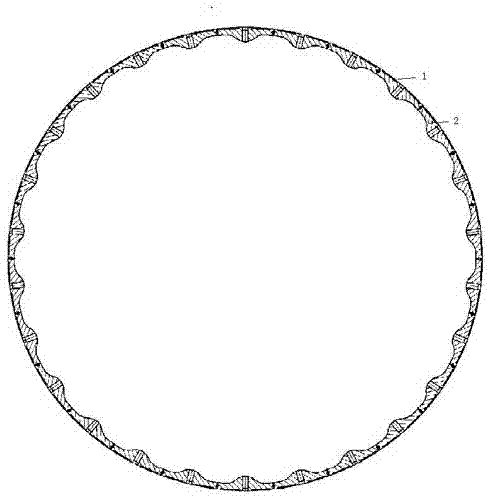

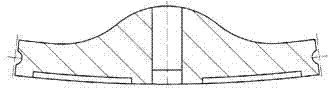

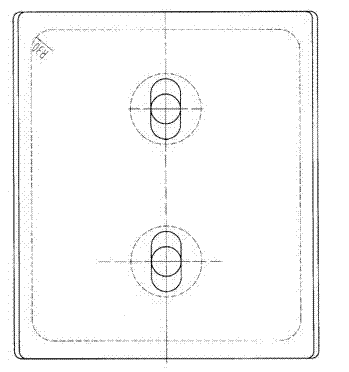

[0012] Such as Figure 1-3 As shown, the cylinder body 1 is provided with a steel lining plate 2, which is evenly fitted and arranged on the inner wall of the cylinder of the rod mill and fixed on the inner wall of the cylinder, especially arranged in the form of figure 1 The lining boards are attached to the left and right in one turn. Each lining board is rectangular, and its cross-sectional shape is shown in the figure: the middle is a protruding arc, and the height of the protruding arc is 1.8 of the edge height (thickness) of the lining board. -2.4 times, such as 2 times; the edge height (thickness) of the liner is 20-30mm; actually it is related to the diameter and rotation speed of the entire cylinder, if it is used for a diameter of 4-4.4 meters, the protruding height is 2.2 times, , the width of the protruding arc is 0.3-0.7 times of the width of the entire liner;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com