Photoelectric conversion element and method for manufacturing same

A technology for photoelectric conversion elements and manufacturing methods, which is applied to electrical elements, electrical solid-state devices, circuits, etc., can solve problems such as leakage paths, increase dark current, and increase stress, and achieve the effect of suppressing cracks and suppressing the increase of dark current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described below with reference to the drawings. Description will be given in the following order.

[0034] 1. Embodiment (Example in which an i-type semiconductor layer is formed within a range from the inside of the contact hole to the upper surface of the first interlayer insulating film)

[0035] 2. Modifications 1 and 2 (example of forming a contact hole by two etching process steps)

[0036] 3. Modifications 3 and 4 (example of patterning i-type semiconductor layer in contact hole)

[0037] 4. Application examples (examples of photoelectric conversion devices and radiation imaging devices using photoelectric conversion elements)

[0038] 1. Example

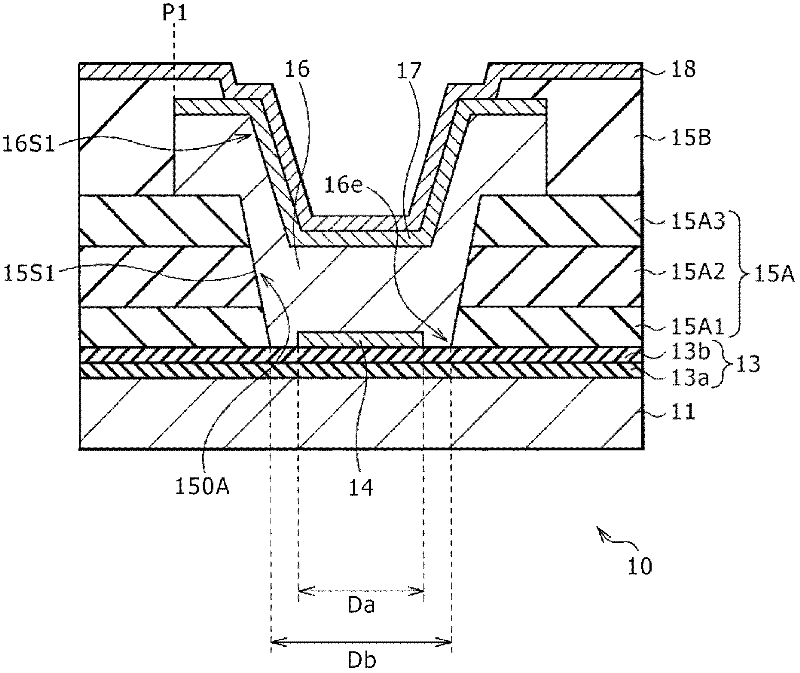

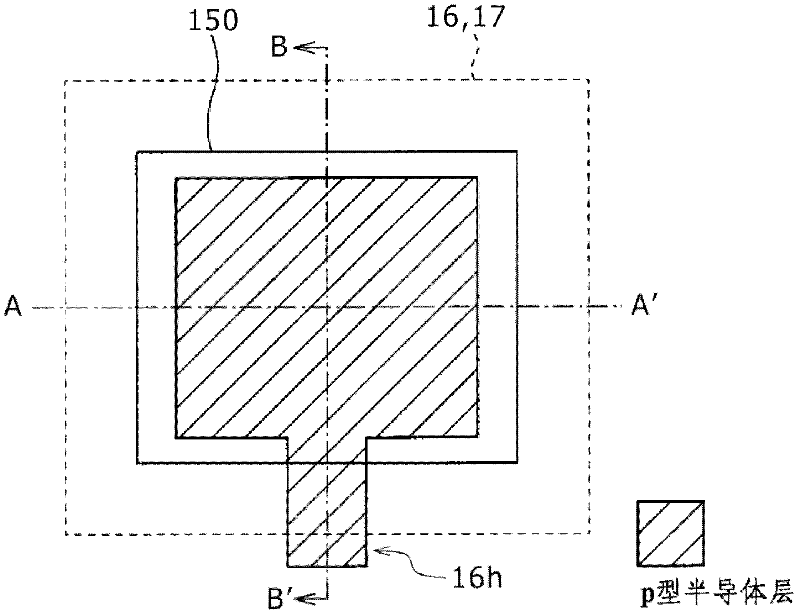

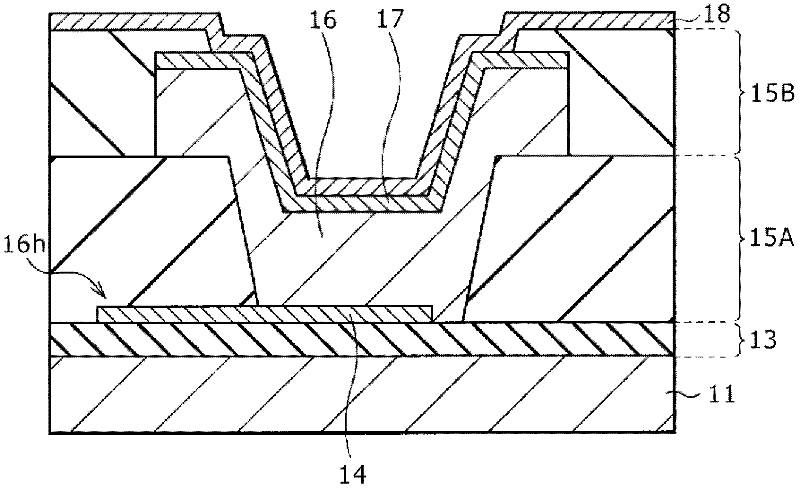

[0039] figure 1 A schematic structure of a photoelectric conversion element 10 according to an embodiment of the present invention is shown. The photoelectric conversion element 10 is a positive-intrinsic-negative (Positive Intrinsic Negative, PIN) photoelectric device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com