Anticorrosive wear-resistant centrifugal pump volute casing

A centrifugal pump and volute technology, applied in the field of corrosion-resistant and wear-resistant centrifugal pump casings, can solve problems such as difficulty in forming and processing, and achieve the effects of high cost performance, prolonging maintenance period and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

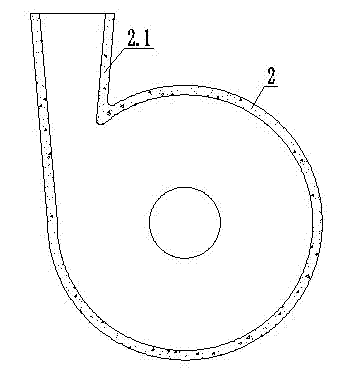

[0033] Example 1: see Figure 5 -8. The volute of the corrosion-resistant and wear-resistant centrifugal pump of the present invention , It includes a plastic volute 4 with an opening on one side and a complete liquid outlet pipe section formed by an asymmetrical side section. A metal embedded part 8 for connection is pre-embedded in the plastic volute, and there is a shaft hole on the bottom of the volute. The outer circumference of the lining aluminum oxide cap-shaped inlay 5 is slightly smaller than the inner wall of the volute, the surrounding wall has a liquid outlet 9 and no pipe section of the liquid outlet, and the bottom surface has a shaft hole 7, and the ceramic inlay is inserted into the rear end of the volute from the opening side of the volute Shrink the end face of the volute by 2mm. 6.1 ( Image 6 ), after the ceramic inlay is embedded in the plastic volute, a castable solid material (such as cement mortar) filled with solid mineral particles is poured in the...

Embodiment 2

[0035] Example 2: see Figure 10 , as mentioned above, the thickness of the surrounding surface of the plastic volute 4 is axially inward, and the pressure-resistant (pull) metal squirrel cage skeleton pressure-bearing support 12 with connecting nuts 11 is embedded in the bottom surface, which is for the axial alignment when the pump is assembled and clamped. Provide rigid anti-compression support to the clamping force, which can prevent the compression deformation of the volute when the pump cover is assembled, enhance the anti-deformation performance of the plastic volute, and improve the structural strength and mechanical stability. The axial width of the squirrel cage framework is slightly smaller than that of the pump casing, so that it is retracted into the plastic pump casing to prevent the transmission medium from corroding the metal support.

Embodiment 3

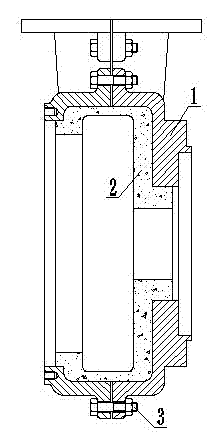

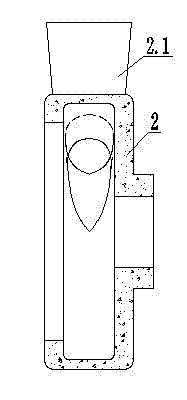

[0036] Embodiment 3: see Figure 11 , as in Example 1, wherein the centrifugal pump volute is a plastic-lined volute with a metal casing 1 lined with a plastic layer 13, and the ceramic wear-resistant inlay 5 as in Example 1 is inlaid in the plastic-lined layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com