Screw-type and piston-type combined double-stage compressor set and intermediate container

A technology of screw compressors and compressor units, which is applied in the direction of machines/engines, liquid displacement machinery, mechanical equipment, etc., can solve the problems of scattered auxiliary equipment, large footprint, and complicated operation, and achieve simplified equipment and equipment operation Reliable, volume-efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

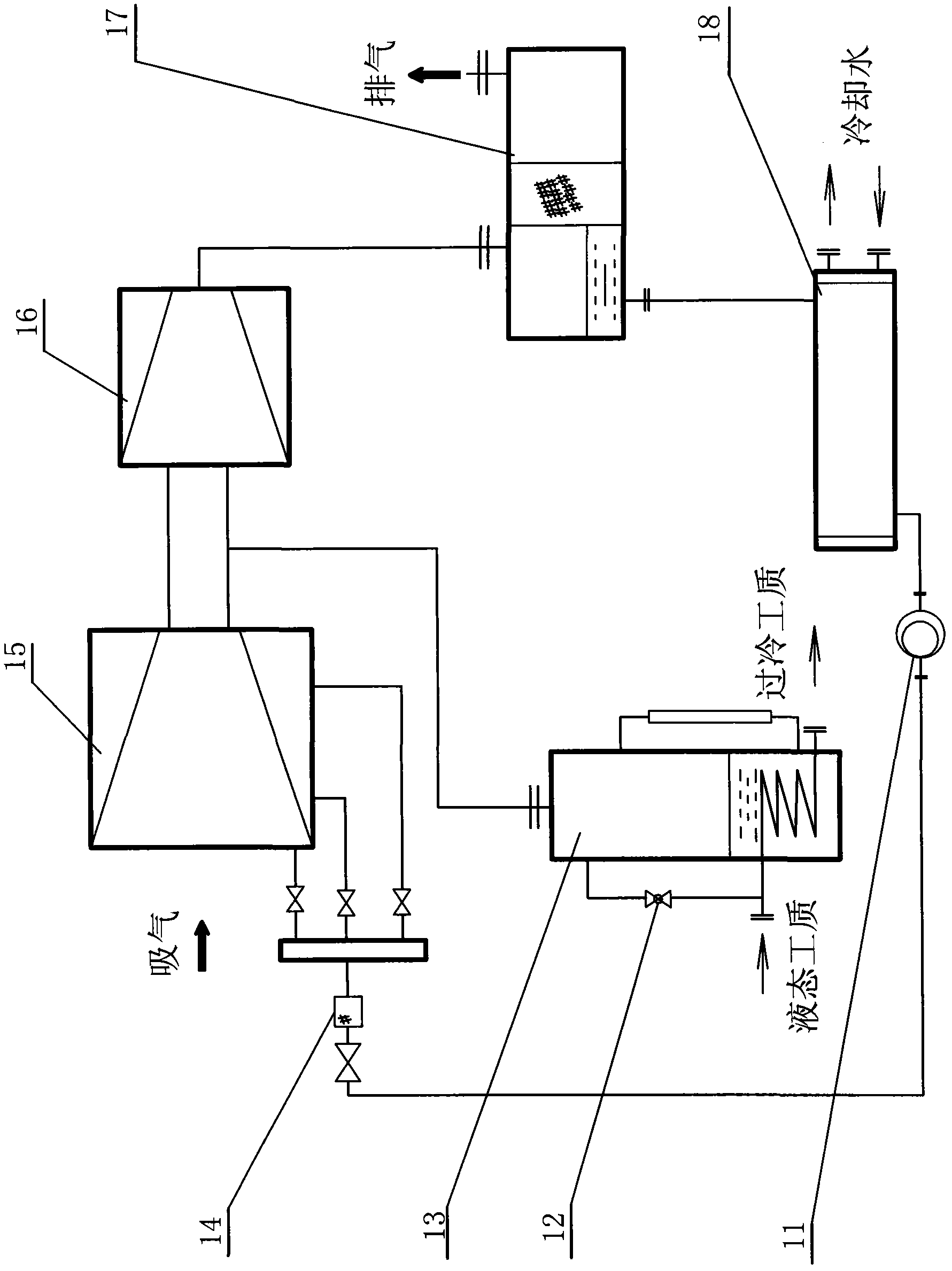

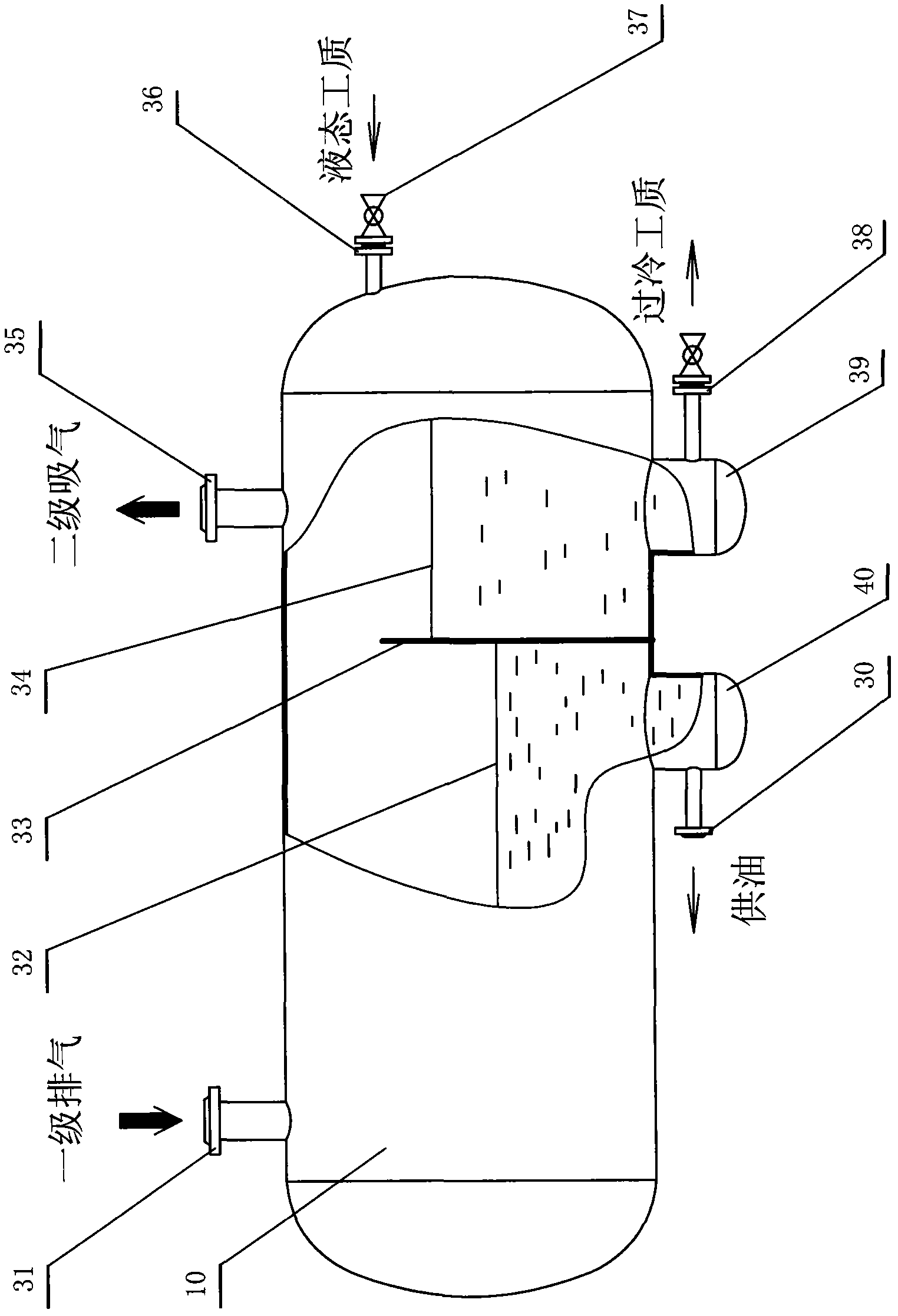

[0024] Embodiment 1, a kind of screw type that is provided with horizontal intermediate container and piston type mixing two-stage compressor unit and horizontal intermediate container (see image 3 , 5 ) is a two-stage compressor unit composed of a one-stage screw compressor 51, a two-stage piston compressor 55 and a horizontal intermediate container 10. A horizontal intermediate container is connected between the exhaust pipeline of the first-stage screw compressor and the suction pipeline of the second-stage piston compressor. The horizontal intermediate container 10 is a horizontal tank, and the inside of the tank is divided into a section (left section) of a cavity 32 for storing oil, and another section (right section) of a cavity 34 for storing liquid working fluid. And the partition plate 33 of setting. There is a gap on the upper part of the partition, which communicates with the cavity for storing oil and the cavity for storing liquid working fluid, and can also be...

Embodiment 2

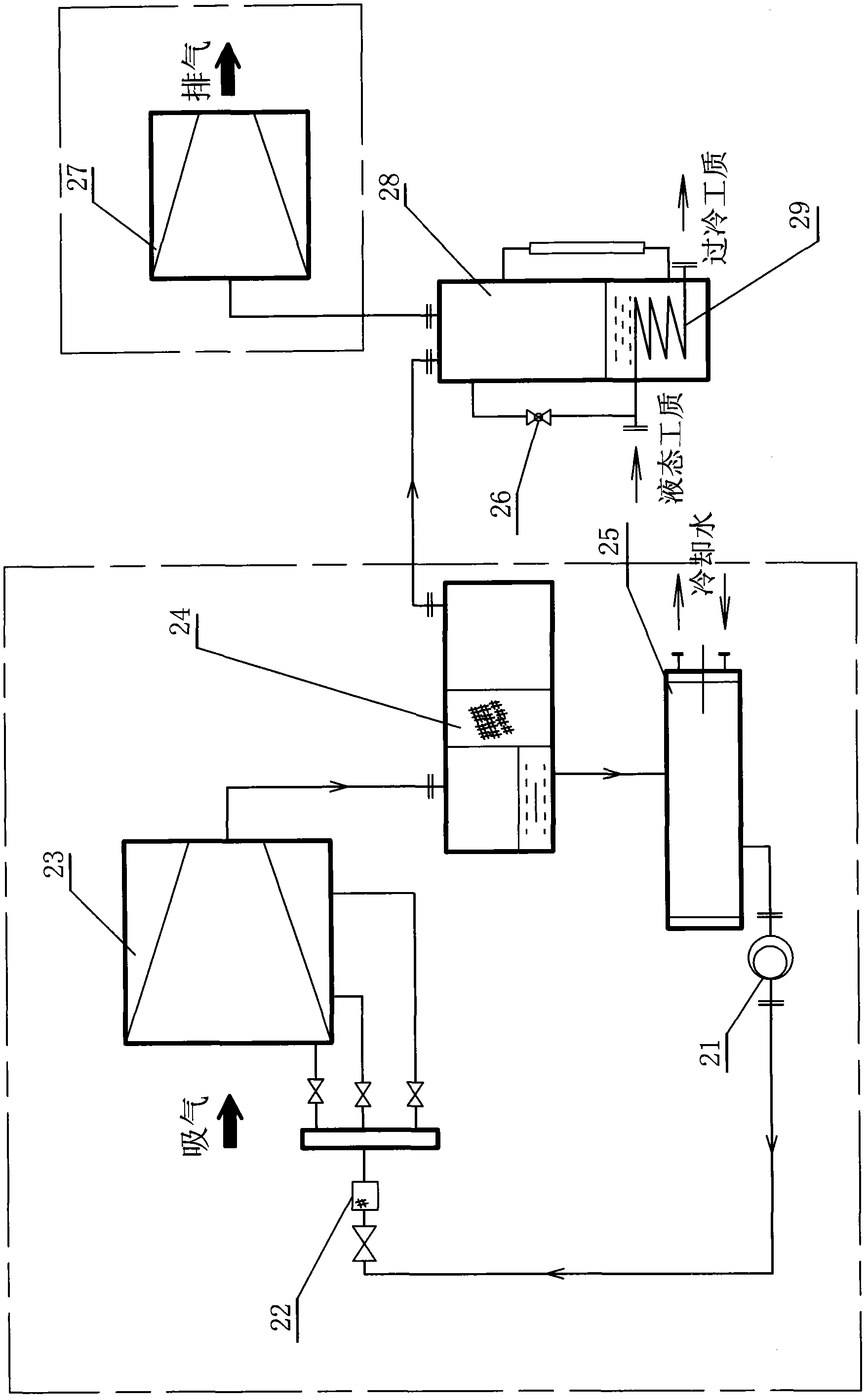

[0025] Embodiment 2, a kind of screw type that is used in refrigeration system and is provided with vertical intermediate container screw type and piston type mixed two-stage compressor unit and vertical intermediate container (see Figure 4 , 7 ) is a two-stage compressor unit composed of a one-stage screw compressor 71, a two-stage piston compressor 73 and a vertical intermediate container 72. There is a vertical intermediate container ( Figure 4 ). The vertical intermediate container is a vertical tank, and the tank is provided with a partition 47 that separates the inner cavity of the tank into one section (lower section) for oil storage, and the other section (upper section) for storage of liquid working fluid. There is a through pipe 44 in the middle of the partition, which is used as a channel to communicate with the cavity for storing oil and the cavity for storing liquid working fluid. The primary exhaust pipeline 42 communicates with the upper part of the oil sto...

Embodiment 3

[0026] Embodiment 3, a screw-type and piston-type mixed two-stage compressor unit used in a refrigeration system and provided with a horizontal intermediate container and a horizontal intermediate container with a heat exchange pipeline (see Image 6 and see image 3 ), a two-stage compressor unit consisting of a first-stage screw compressor 61, a second-stage piston compressor 65, and a horizontal intermediate container 10. A horizontal intermediate container is connected between the exhaust pipeline of the first-stage screw compressor and the suction pipeline of the second-stage piston compressor. The horizontal intermediate container is a horizontal tank, and there is a partition in the tank that divides the inner cavity of the tank into one section (left section) for oil storage, and the other section (right section) for storage of liquid working fluid ( 33), the gap on the upper part of the partition communicates with the cavity for storing oil and the cavity for storing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com