Method for simultaneously preparing albiflorin and paeoniflorin

A technology for paeoniflorin and paeoniflorin, which is applied in the field of medicine, can solve the problems such as disclosure of the process route of unhigh-purity paeoniflorin and high-purity paeoniflorin, harsh operating process control conditions, unsuitability for large-scale production, and the like. The operating process conditions are easy to control, the quality controllability is strong, and the energy consumption is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

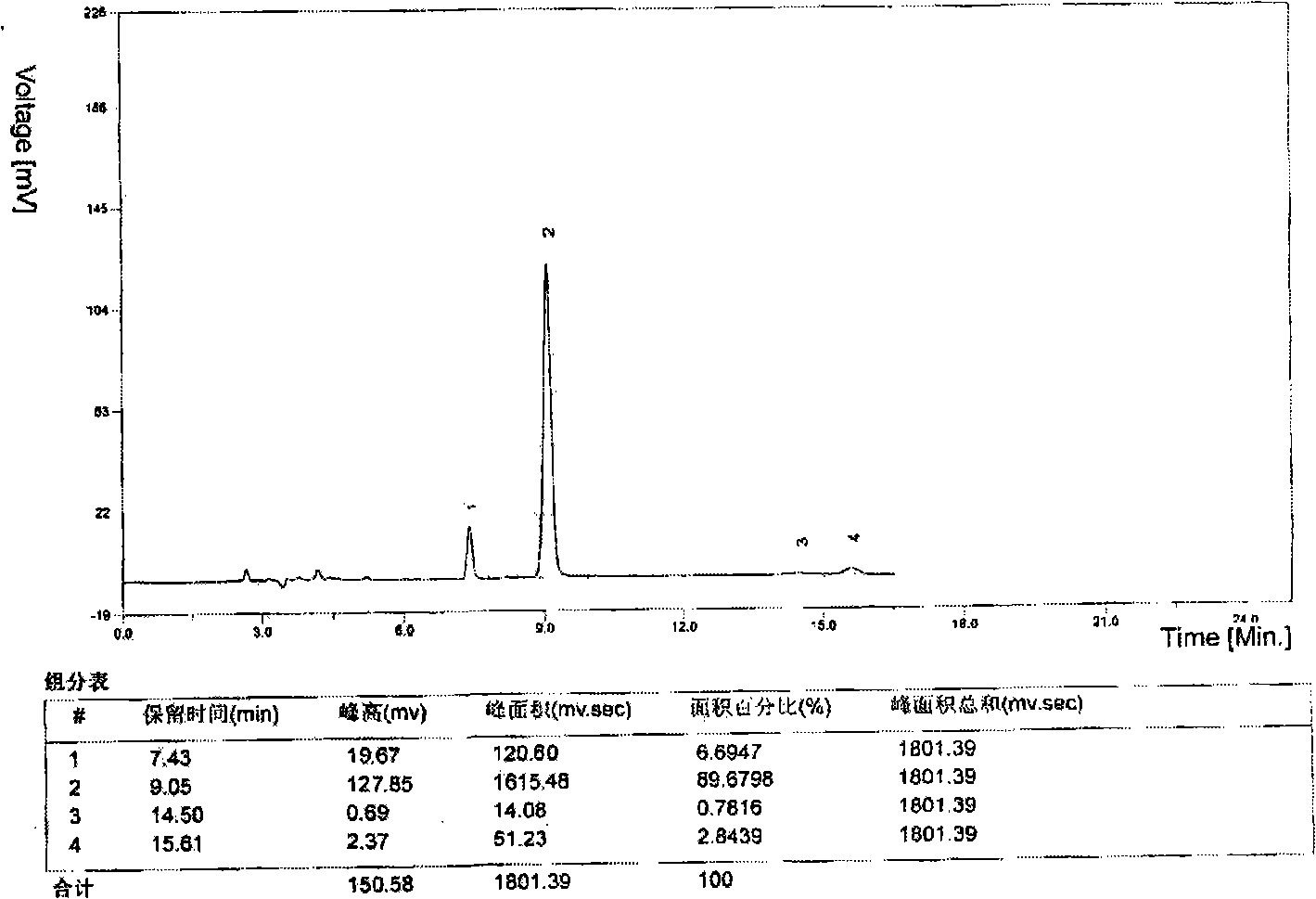

Image

Examples

Embodiment 1

[0034] 1. Extraction of medicinal materials

[0035] 150 kilograms of dry peony roots, after being crushed into coarse powder, put into 2 tons of stainless steel traditional Chinese medicine extraction tanks, add mass percent concentration and be 70% ethanol solution, heat and reflux and extract three times, the volume of the ethanol solution used for extraction is 1200L successively, 900L, 900L, the extraction time is 3h, 2.5h, 2h in turn.

[0036] After combining the three extracts, use a vacuum decompression concentration tank (produced by Wuxi Huaxin Pharmaceutical Equipment Co., Ltd.) to carry out decompression concentration until it has no alcohol smell, and obtain a peony concentrate, wherein the temperature of decompression concentration is 70°C , the relative vacuum is -0.09~-0.075MPa, the relative density of the peony concentrate is 1.25, and the volume is 220L.

[0037] 2. Separation

[0038] 1) Add 700L of 95% ethanol to the peony concentrate, let it stand overni...

Embodiment 2

[0048] 1. Extraction of medicinal materials

[0049] 300 kilograms of fresh Paeoniae Alba root, chopped, put into 3 tons of traditional Chinese medicine extraction tanks, add ethanol with a concentration of 40% in mass percentage, heat and reflux for three times, the volume of ethanol used for extraction is 2200L, 1800L, 1800L, and extract The time is 3h, 3h, 2h in turn;

[0050] After the three extractions are combined, use a vacuum decompression concentration tank to carry out decompression concentration until there is no alcohol smell to obtain a peony concentrate, wherein the temperature of decompression concentration is 60°C, and the relative vacuum degree is -0.09~-0.08MPa , the relative density of peony concentrate is 1.21, and the volume is 250L.

[0051] 2. Separation

[0052] 1) Add 800L of 95% ethanol to the peony concentrate, let stand overnight, take the supernatant, concentrate to 250L, add 500L of water to dilute. Adopt macroporous adsorption resin column to ...

Embodiment 3

[0062] 1. Extraction of medicinal materials

[0063] 100 kg of dried peony roots were crushed into coarse powder, soaked in 400L of deionized water for 5 hours, put into a 1-ton stainless steel percolation tank, percolated with deionized water, and collected about 1500L of percolation liquid.

[0064] 2. Separation

[0065] 1) The percolation liquid is separated by a macroporous adsorption resin column. Among them, the macroporous adsorption resin is AB-8 type macroporous adsorption resin. The column volume of the macroporous adsorption resin column is 150L. For 50% ethanol elution, the elution flow rate is 100L / h, and the eluate is collected, and every 50L eluate is collected as a fraction;

[0066] 2) Use thin layer chromatography (TLC method) to detect the content of paeoniflorin and paeonifloride in the collected eluent, and the eluate fraction containing paeoniflorin or paeonifloride (or both) Merge together to obtain the resin column eluate, wherein, the thin-layer pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com