Spiral-flow type crystal phosphorous removal reactor

A crystallization dephosphorization, swirling flow technology, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of fewer phosphorus removal reactors, achieve enhanced reaction rate, ensure Phosphorus removal effect, effect of ensuring precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

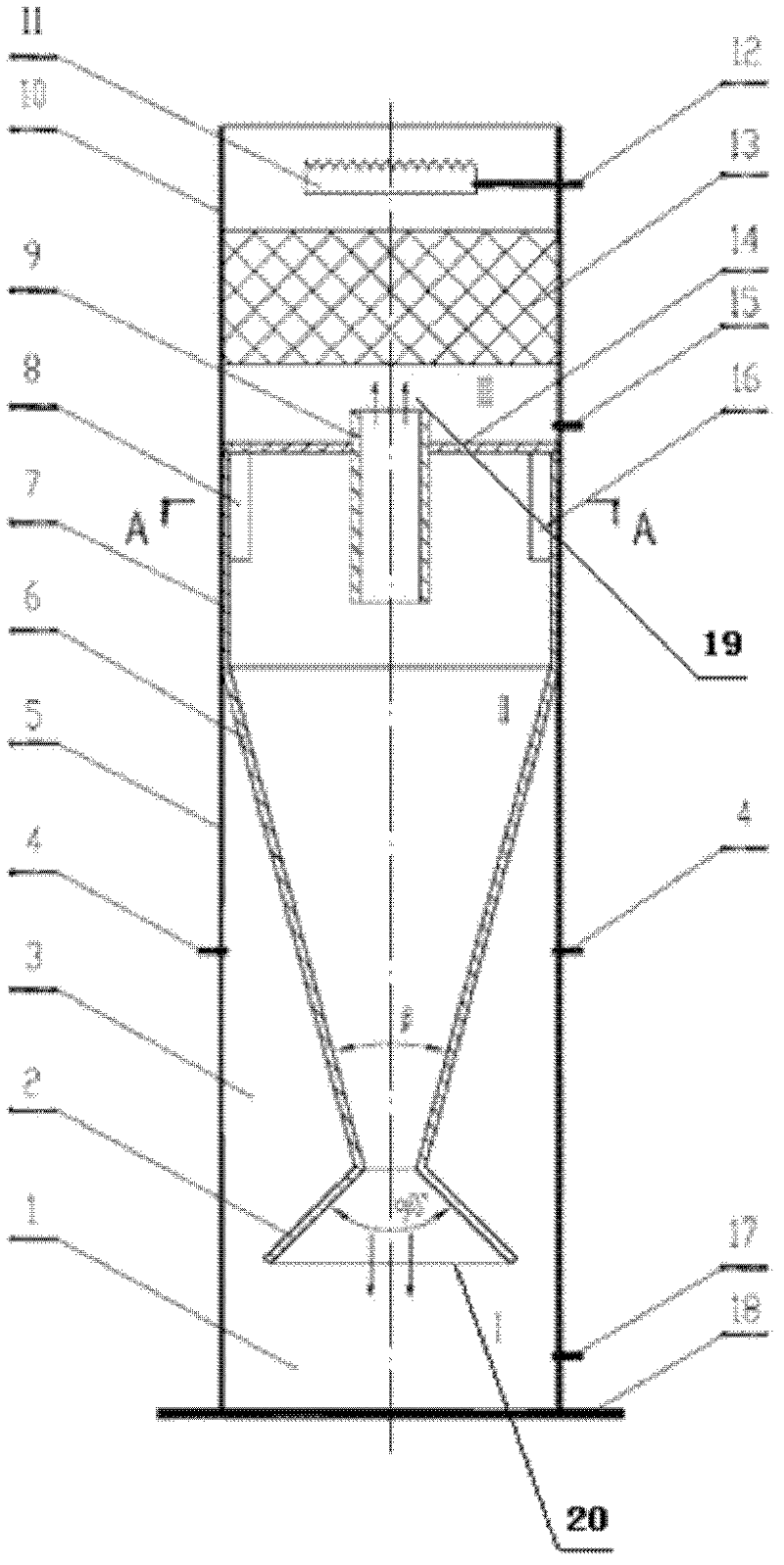

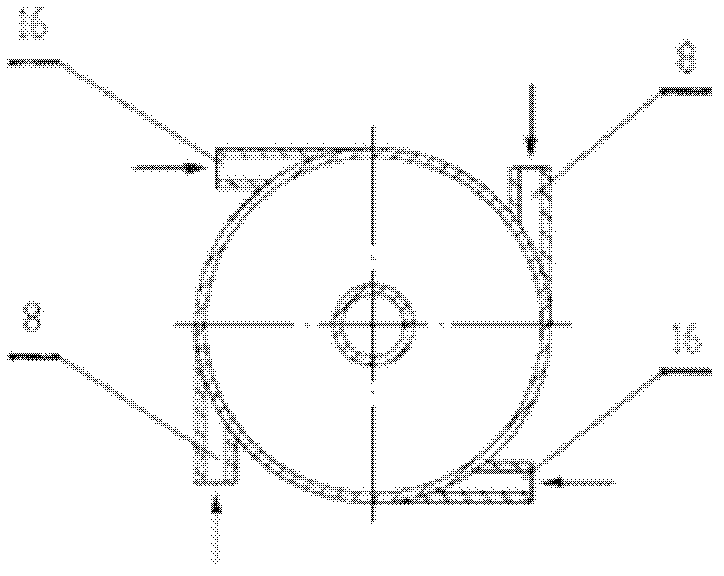

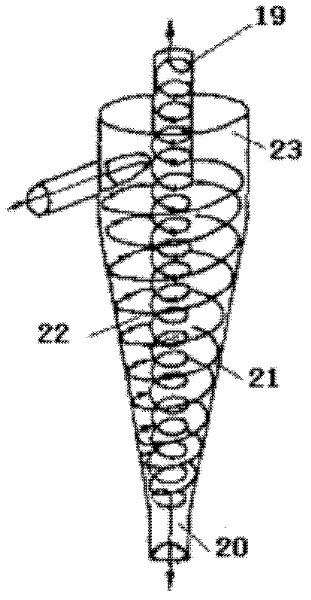

[0030] Such as figure 1 As shown, the present invention is a cyclone crystallization dephosphorization reactor, which includes an underflow area I, a hydrocyclone area II and an overflow area III from bottom to top, and the underflow area I realizes the precipitation function of granular crystalline phosphorus salts; The hydrocyclone zone II realizes the separation function of particles and floc crystalline phosphorus salts; the overflow zone III realizes the function of granulating floc crystalline phosphorus salts; the underflow zone I includes a bottom plate 18, and the bottom plate 18 is connected with a lower column 5; the lower column 5 is provided with a recovery pipe 17 and two return pipes 4; the hydrocyclone zone II includes an inverted bell mouth 2, a cone 6 and a central column 7; the inverted bell mouth 2 extends into the underflow area I, and its upper end is connected to the lower end of the cone 6; the cone 6 extends into the underflow area I, and its upper end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com