System and method for treating organic wastewater of circuit board

A technology of organic wastewater treatment and circuit board, which is applied in the direction of osmosis/dialysis water/sewage treatment, combustion method, lighting and heating equipment, etc. It can solve the problems that the circuit board cannot effectively treat organic wastewater and the treatment effect is not good, and achieve resistance Strong membrane fouling ability, better treatment effect, and the effect of solving fouling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

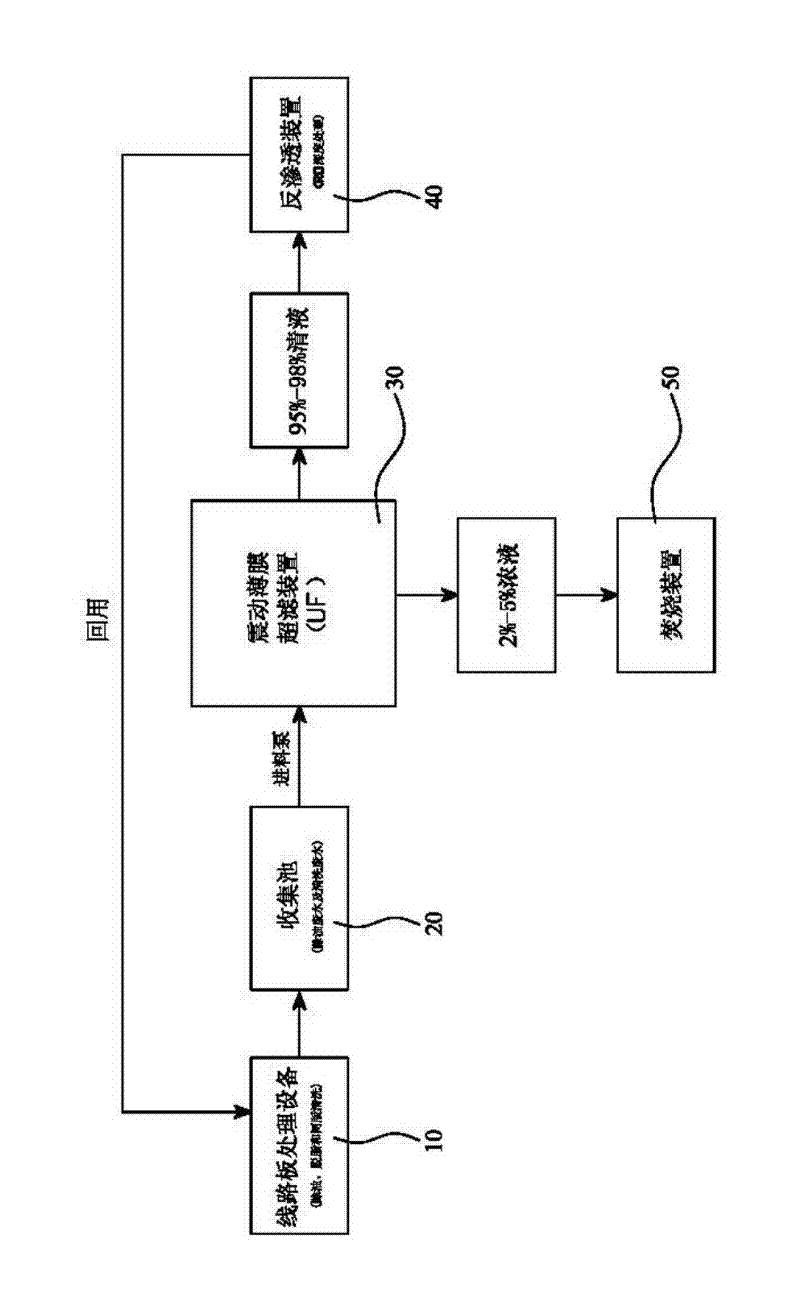

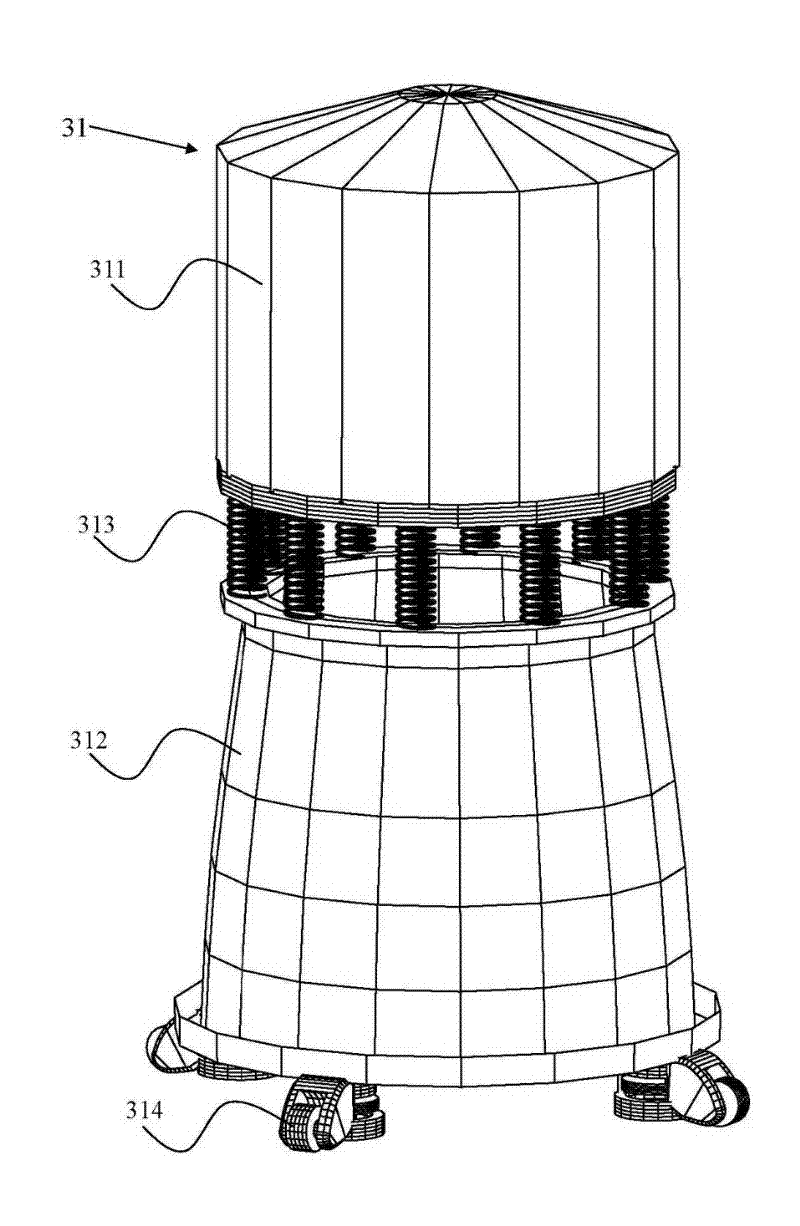

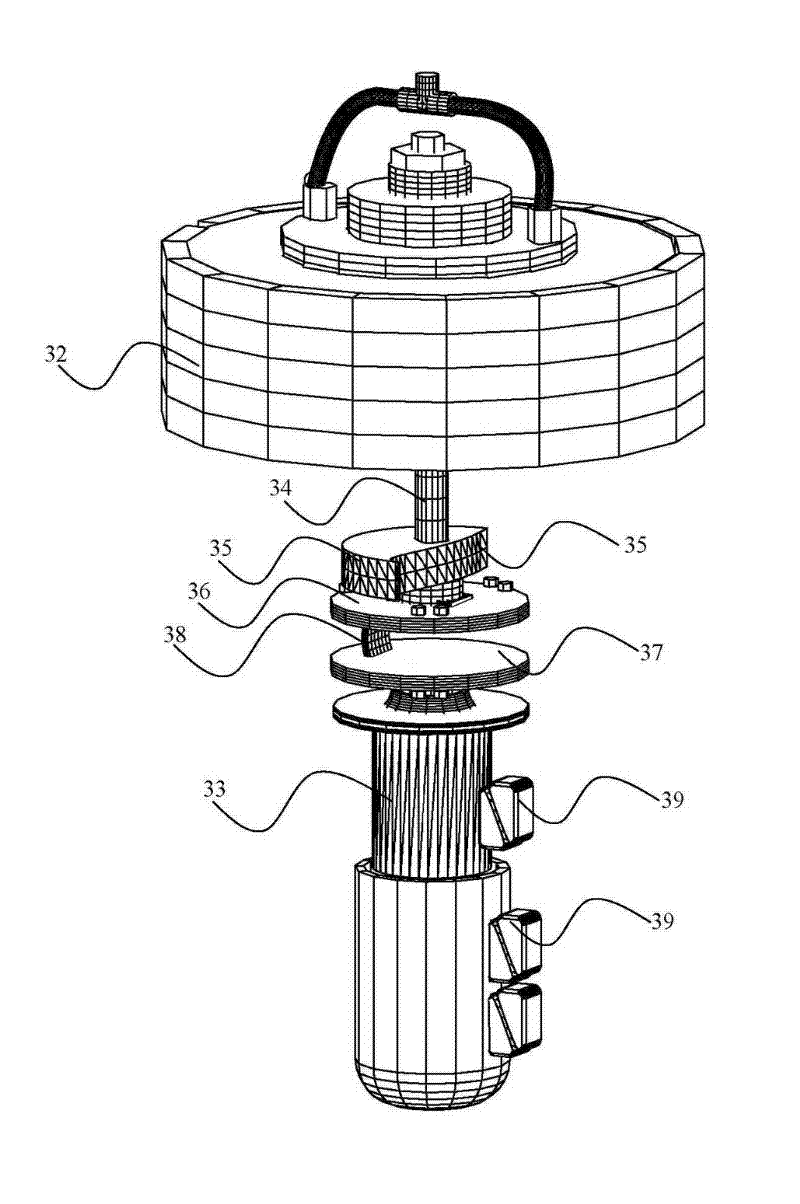

[0071] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including circuit board processing equipment 10 , collection tank 20 , vibration membrane ultrafiltration device (UF) 30 , reverse osmosis device 40 and incineration device 50 .

[0072] Among them, such as figure 1 As shown, the circuit board processing equipment 10 is used for degreasing, degreasing and screen cleaning of the circuit board to generate degreasing wastewater and cleaning wastewater.

[0073] The collection pool 20 is used to collect the degreasing waste water and cleaning waste water output from the circuit board processing equipment 10 , and the input port of the collection pool 20 communicates with the output port of the aforementioned circuit board processing equipment 10 .

[0074] The vibrating membrane ultrafiltration device (UF) 30 is used to filter and separate the wastewater output from the collection tank 20 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com