Industrially-used glue-applying device

A glue application device and an industrial technology, which is applied to devices and coatings that apply liquid to the surface. Good performance, high brushing efficiency, and the effect of reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

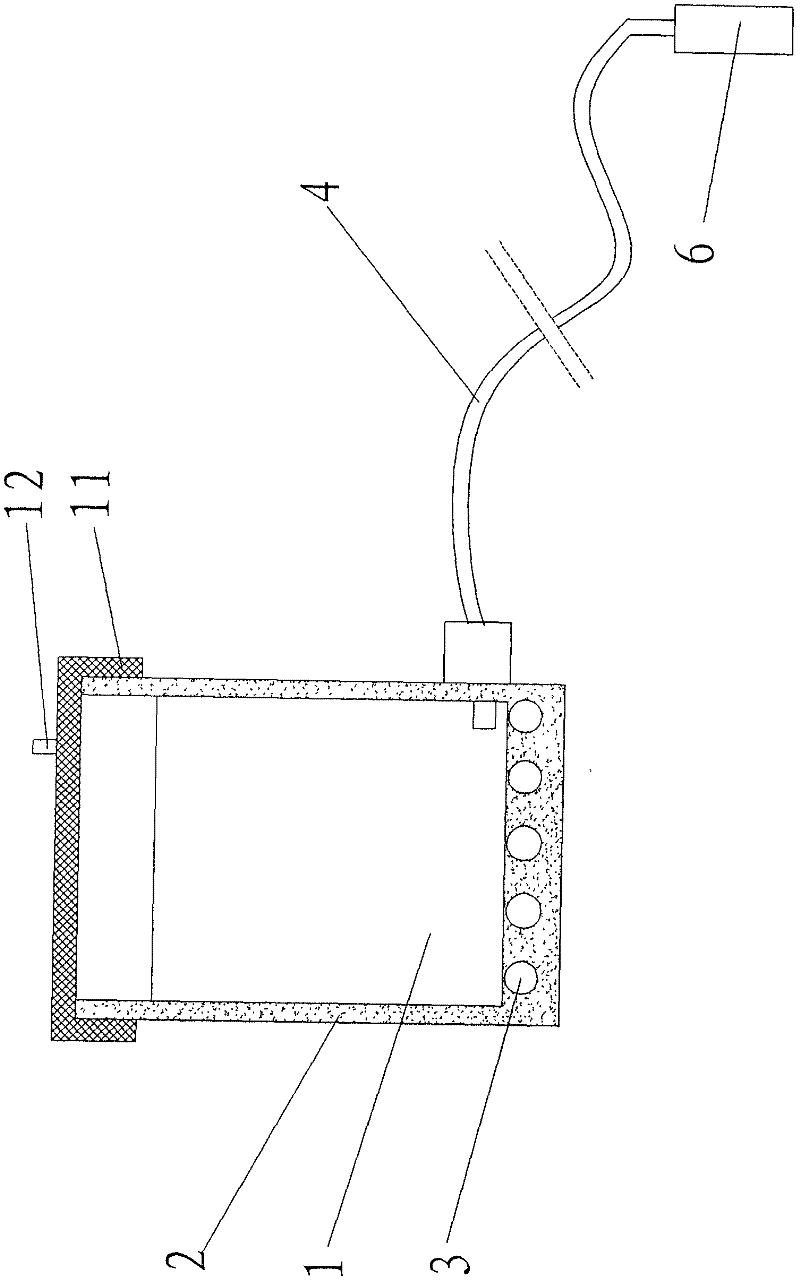

[0017] Such as figure 1 As shown, the present invention is composed of a glue storage tank 1, a hose 4, and an applicator head 6. The hose 4 connects the glue storage tank and the applicator head, and the glue storage tank is arranged at a higher position so that the gravity of the glue liquid can be produced. artesian. The rubber storage tank 1 is made into a sandwich structure, and the interlayer is filled with heat insulating materials to form a heat insulation layer 2. An electric heating element 3 is embedded in the interlayer at the bottom of the rubber storage tank. The rubber storage tank is also equipped with a tank cover 11, and the tank cover has a vent hole 12. Keep the same air pressure inside the tank as outside.

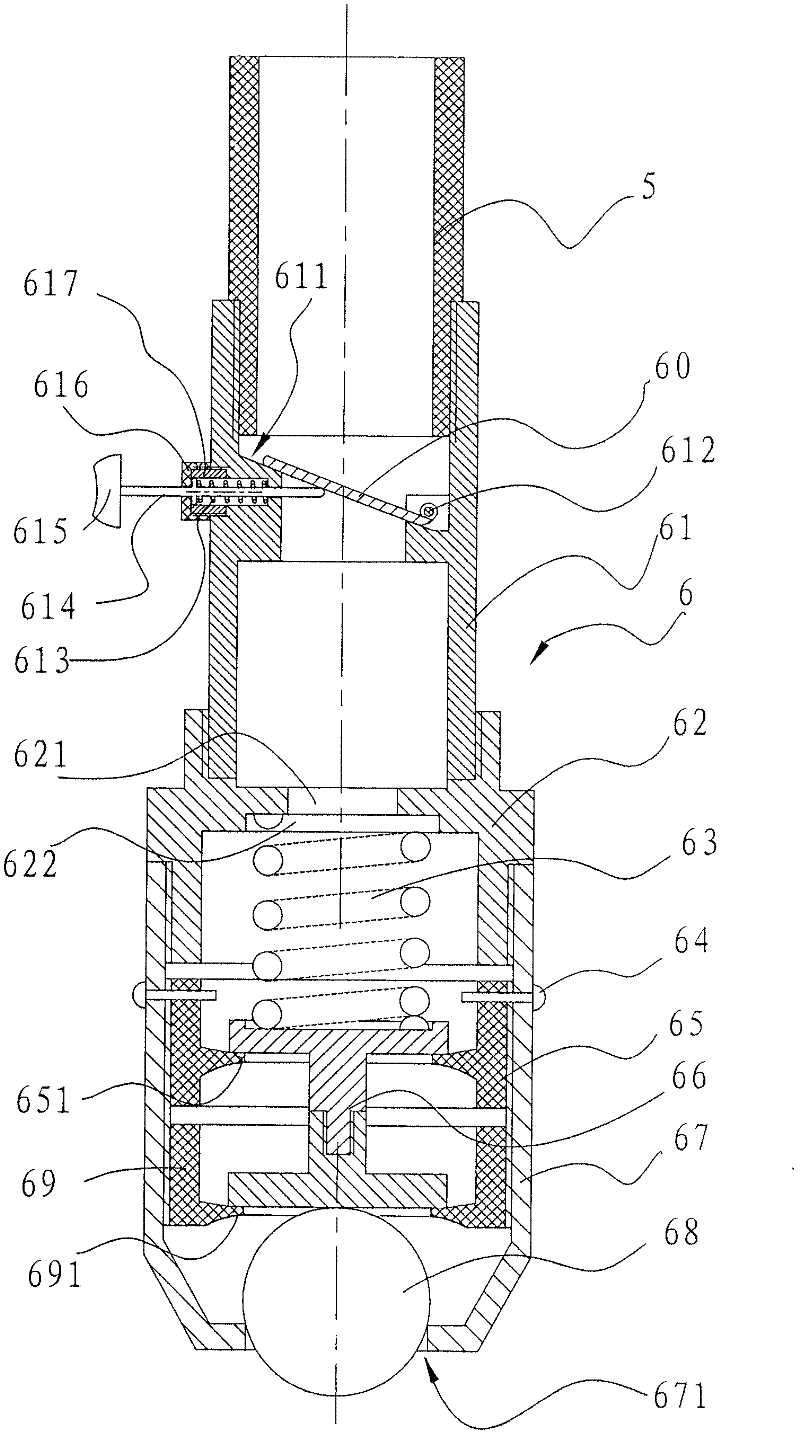

[0018] Such as figure 2 , image 3 As shown, the applicator head 6 includes a main valve 61 , a spring seat 1 62 and a glue outlet 67 . The upper end of the main valve 61 is threadedly connected with the pipe joint 5, and the pipe joint 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com