Efficient production process for V-belts

A production process and technology of triangular belts, which are applied to belts, other household appliances, household appliances, etc., can solve the problems of unstable product quality, complex production process, high production cost, etc., and achieve stable product quality, good overall strength, and high production line efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

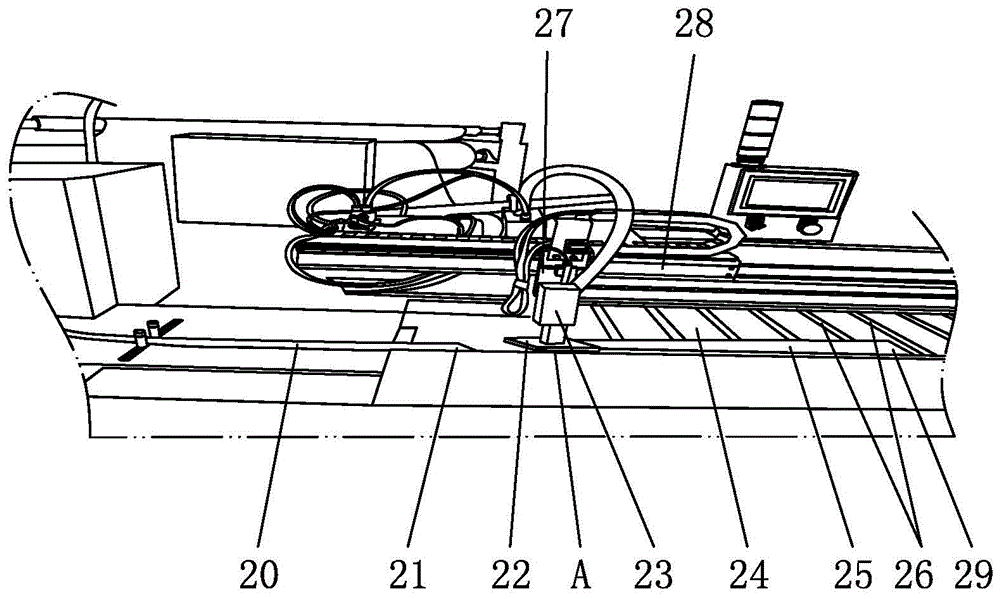

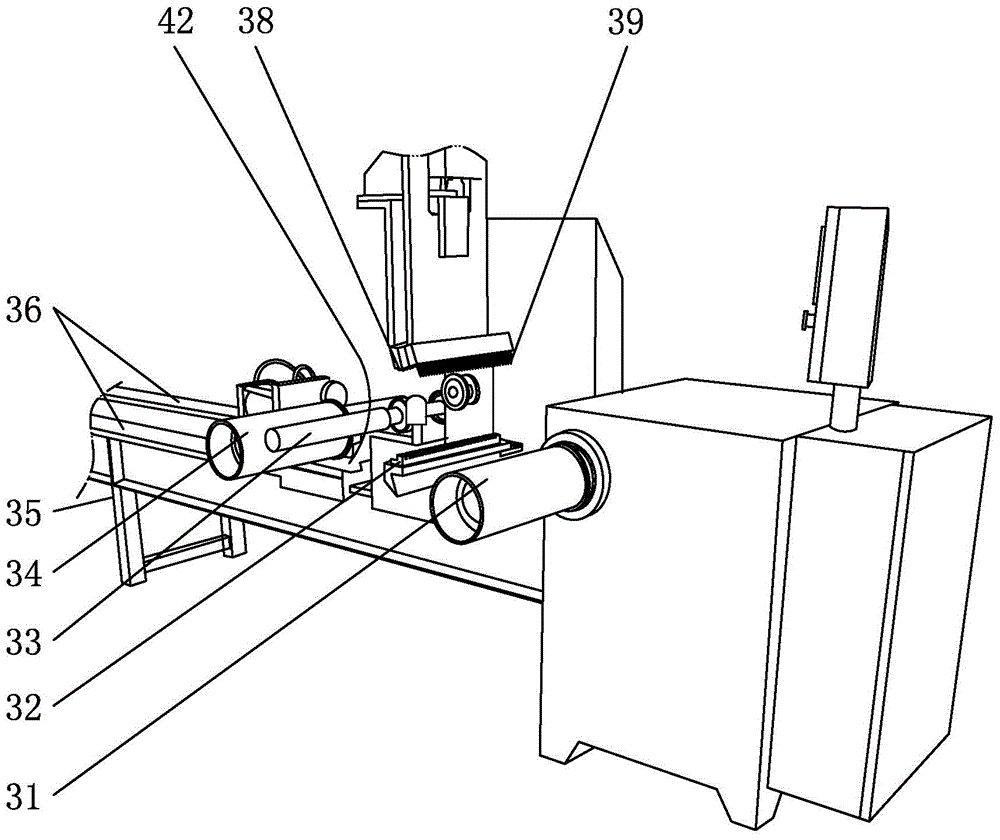

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 4 :

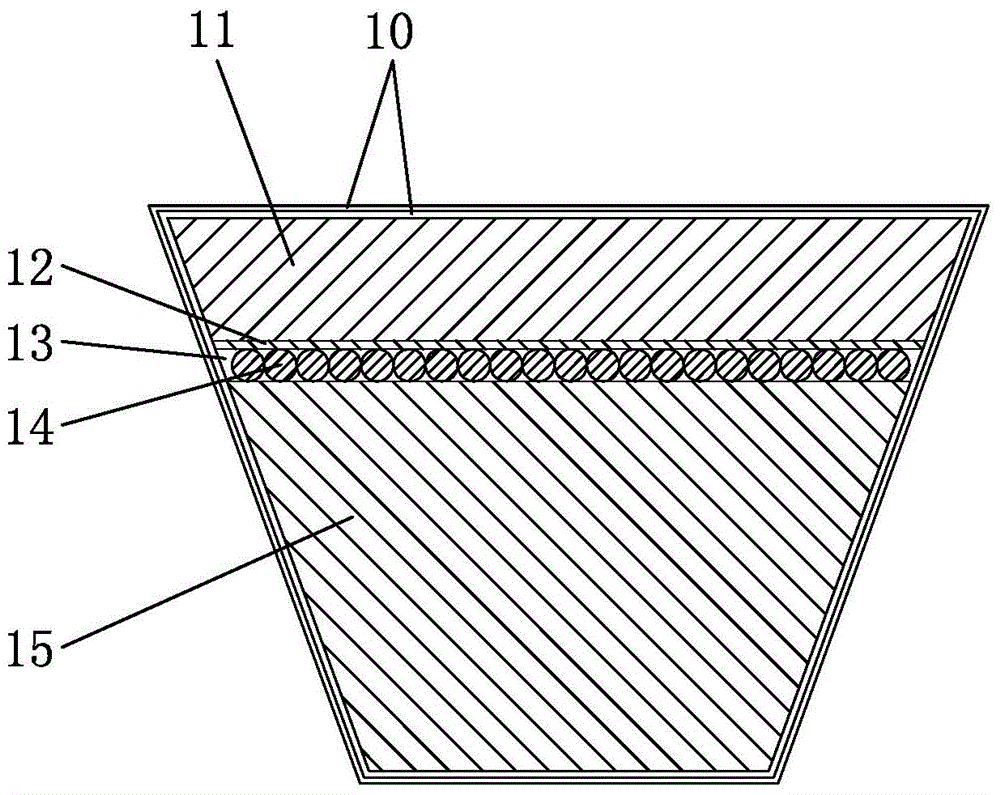

[0028] The high-efficiency production process of the V-belt includes the following processes: firstly manufacture the edge wrapping layer 10, the stretch adhesive layer 11, the strength layer, and the compression adhesive layer 15 for producing the V-belt respectively, and then make the edge wrapping layer 10, the tension adhesive layer 15 and The stretching rubber layer 11, the strength layer and the compression rubber layer 15 are synthesized into a V-belt blank at one time, and finally the V-belt blank is vulcanized to form a finished V-belt, wherein:

[0029] The production process of the edge-wrapping layer 10 is as follows: install the material roll with the dipped cloth on the cloth release stick, and the dipped cloth on the cloth release stick is intermittently transported to the lower side of the automatic cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com