Processing method for wind and wave resistance square metal net box

A technology of anti-wind and wave, net cage, applied in fish farming, application, climate change adaptation, etc., can solve problems such as wear and tear of metal mesh, achieve the effect of improving geometric structure, improving comprehensive benefits, and solving energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

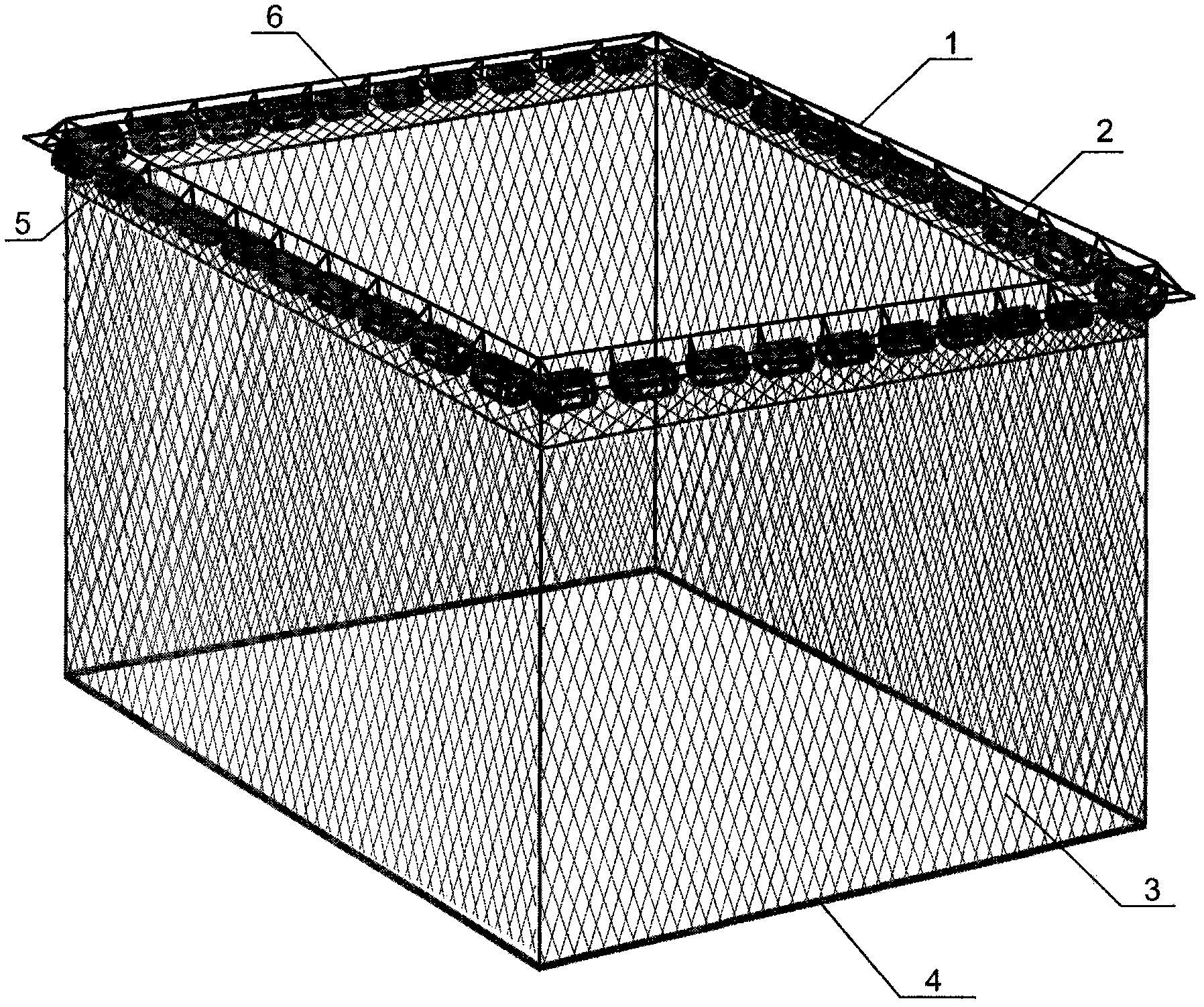

[0007]The anti-wind and wave square metal cage mesh system consists of double-layer synthetic fiber mesh as the first mesh (6 in the picture), metal orthorhombic mesh as the second mesh (3 in the picture), and the first mesh The longitudinal canvas soft connection between the sheet and the second mesh (5 in the figure), the square metal mesh is the combined mesh form of the square mesh at the bottom of the cage box, and the first mesh in the vertical direction of the cage box The height of the mesh is 0.2 to 1.5 meters, and one of the heights can be used in this height range, for example, 0.8 meters, and the height of the second mesh in the longitudinal direction of the cage body is 2.5 to 15.0 meters, and one of them can be used in this height range Height, such as 8.1 meters, the side length of the square mesh at the bottom of the cage body is 1 to 30 meters, one of the lengths can be used in this length range, for example, the side length of the square mesh is 10 meters, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com