Display method of tempered martensitic steel carbide colour metallography and electrothermal metallographic chromogenic device special for display method

A technique for tempering martensite and color metallography, which is used in electrothermal metallographic color developing devices, and the display field of tempered martensitic steel carbide color metallography, which can solve the problem of heating color and resistance of samples that cannot be inspected on site. The furnace temperature control accuracy is low, the resistance furnace heating is inconvenient to move, etc., to achieve the effect of automatic control of heating temperature and holding time, automatic control of heating temperature and time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

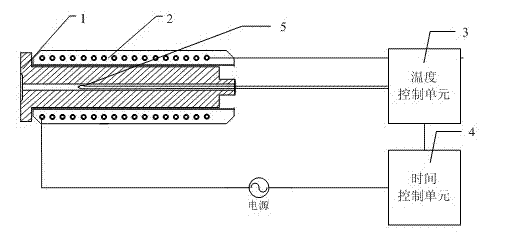

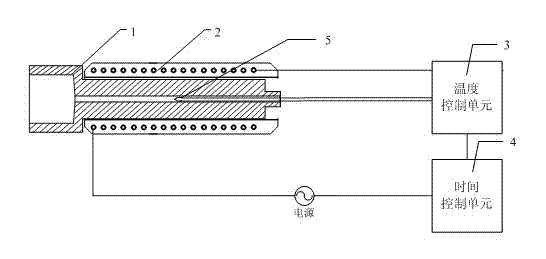

[0053] Figure 1~2 The electrothermal metallographic device shown is an embodiment of the present invention. The electrothermal metallographic color development device consists of a heat-insulating handle, a heat-dissipating jacket 8, a heat-insulating shell 9, a temperature measuring device 5, a heater, a temperature control unit 3 for controlling the heating temperature of the heater temperature, and a time for controlling the heating time. The control unit 4 constitutes. The heater, the temperature control unit 3 and the time control unit 4 are respectively connected to the power supply. The heating temperature controlled by the temperature control unit 3 ranges from 100 to 600°C. The temperature control unit 3 is electrically connected to the time control unit 4, and the output control terminal of the temperature control unit 3 is connected to the input control terminal of the heater for timely controlling the opening and closing of the electric heater. The heater is co...

Embodiment 2

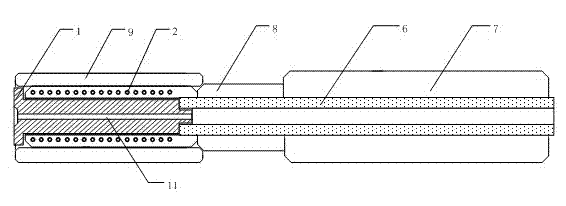

[0057] The difference from Embodiment 1 is: as Figure 3~4 As shown, the working end of the heating element 1 of the electrothermal metallographic color development device is cylindrical, in which the hollow chamber is used to place metal samples, and is used for metal color metallographic samples with a grinding surface diameter φ≤15mm, and the hollow chamber is open A piece of quartz glass sheet 10 slightly larger than its diameter can be covered at the place for heat preservation and observation.

Embodiment 3

[0060] (1) For the tempered martensitic steel T91 steel sample after 85,000 hours of high temperature operation, the smooth grinding surface was trimmed with a grinding wheel, and then coarsely ground with No. 120 and No. 240 coarse sandpaper, and then successively with No. No., No. 1500 and No. 2000 metallographic sandpapers are used for fine grinding. Every time the sandpaper is changed during grinding, the grinding direction of the T91 steel sample should be perpendicular to the direction of the previous grinding mark. Grind until the last grinding mark is removed to fully remove the deformed layer. And the new wear marks are even and consistent. When grinding, the pressure should not be too high, especially when the last sandpaper is ground, it must be lightly ground.

[0061] Wipe the finely ground T91 steel sample with absolute ethanol, move it to a polishing disc equipped with woolen cloth, nylon silk, velvet or other velvet with fine and uniform fibers, and polish it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com