Environmentally-friendly quick drying aqueous glass imitation card transfer paint and preparation method as well as application thereof

A transfer coating, environmentally friendly technology, used in paper coatings, coatings, textiles and papermaking, etc., can solve the problems of high cost of finished glass cardboard, heavy odor, poor drying, etc., to achieve good printing adaptability, solid content content High, good printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of an environment-friendly quick-drying water-based imitation glass card transfer coating, the method comprises the following steps:

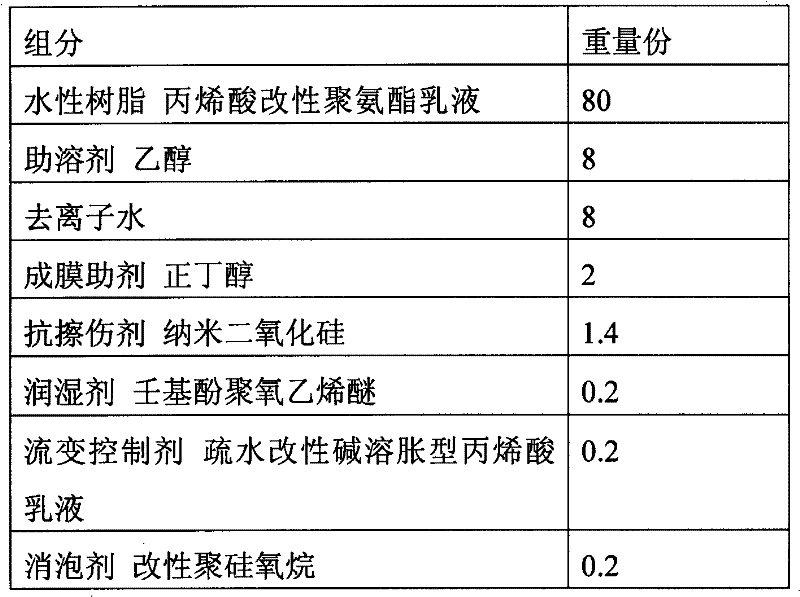

[0047] (1) Prepare materials according to the following components and content (parts by weight):

[0048]

[0049] (2) Put the water-based resin into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0050] (3) After mixing the co-solvent, deionized water and film-forming aids evenly, add them to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0051] (4) Add anti-abrasion agent, wetting agent, and rheology control agent to the reaction kettle in sequence, and stir at a medium speed of 700-800 rpm for 10-20 minutes;

[0052] (5) Add a defoamer into the reaction kettle, stir at a high speed of 1000-1200 rpm for 20-30 minutes, and obtain an environment-friendly quick-drying water-based imitation glass card transfer coating.

[0053] Apply the above...

Embodiment 2

[0055] A preparation method of an environment-friendly quick-drying water-based imitation glass card transfer coating, the method comprises the following steps:

[0056] (1) Prepare materials according to the following components and content (parts by weight):

[0057] components

parts by weight

Water-based resin acrylic emulsion

95

Co-solvent isopropanol

1

Deionized water

2

Anti-abrasion agent polyethylene emulsified wax

1.6

Wetting agent acetylene glycol

0.2

Defoamer modified silicone defoamer

0.2

[0058] The Tg of the acrylic emulsion is 50°C and the molecular weight is 500,000;

[0059] (2) Put the water-based resin into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0060] (3) After mixing the co-solvent and deionized water evenly, add it to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5 minutes;

[0061] (4) Add an...

Embodiment 3

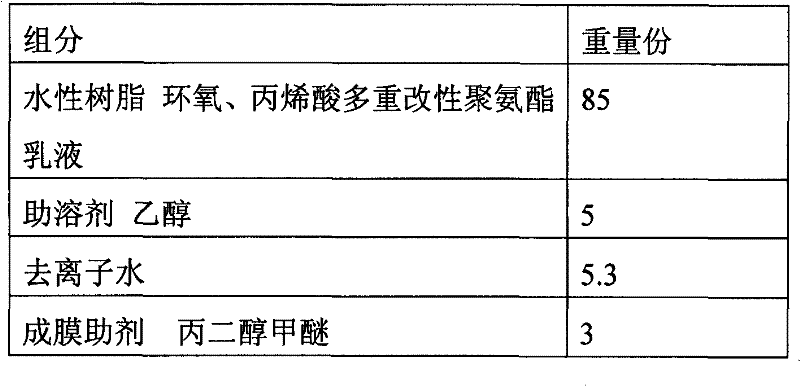

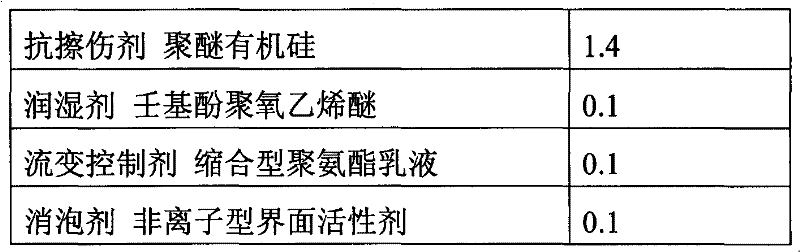

[0065] A preparation method of an environment-friendly quick-drying water-based imitation glass card transfer coating, the method comprises the following steps:

[0066] (1) Prepare materials according to the following components and content (parts by weight):

[0067]

[0068]

[0069] The Tg of the multiple modified polyurethane emulsion is 30°C, and the molecular weight is 50,000-200,000;

[0070] (2) Put the water-based resin into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0071] (3) After mixing the co-solvent, deionized water, and film-forming aids evenly, add them to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 10 minutes;

[0072] (4) Add anti-abrasion agent, wetting agent, and rheology control agent to the reaction kettle in sequence, and stir at a medium speed of 700-800 rpm for 20 minutes;

[0073] (5) Add a defoamer to the reaction kettle, stir at a high speed of 1000-1200 rpm for 30 minutes, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com