Envelope production process for granzyme for temperature-resistant feed

A production process and granule enzyme technology, applied in feed, animal feed, animal feed, etc., can solve problems such as insufficient thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of granule enzyme for temperature-tolerant aquatic feed:

[0033] Mix 10 kg of xylanase, 20 kg of calcium carbonate, 10 kg of ethyl cellulose, 40 kg of corn starch, and 20 kg of water to prepare a paste. The paste is granulated with a rocking granulator to obtain core particles; the granulator used It is a YK-160 swing pellet machine, with a rotating drum diameter of 160 mm, a rotating drum speed of 65 rpm, and a rotating drum swing angle of 365°±10°. The core particles obtained in the granulation step are shot blasted by a shot blasting machine, and finally the particle size of the core particles is controlled at 30-60 mesh. The shot blasting uses the QZL700 shot blasting machine, and the diameter of the shot blasting pot is 700 mm. The shot blasting speed is 100-200 revolutions (adjusted according to production requirements).

[0034] Add about 5% coating solution to 100kg core particles to prepare 8kg coating solution. The coating solution is prepared accordi...

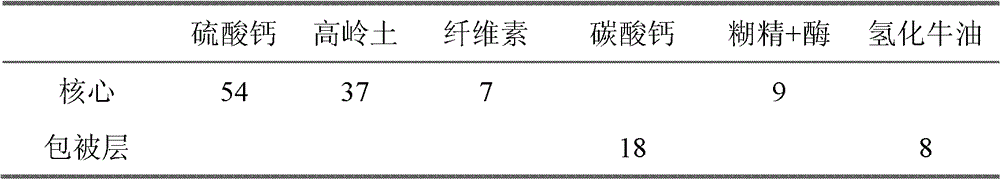

Embodiment 2

[0036] Preparation of granular enzyme for temperature-tolerant poultry feed:

[0037] Preparation of granular enzyme for temperature-tolerant aquatic feed:

[0038] Mix 20 kg of xylanase, 20 kg of calcium carbonate, 15 kg of ethyl cellulose, 30 kg of corn starch and 15 kg of water to prepare a paste. The paste is granulated with a rocking granulator to obtain core particles; the granulator used The model and granulation parameters are the same as in Example 2. The core particles obtained in the granulation step are shot blasted by a shot blasting machine, and finally the particle size of the core particles is controlled at 30-60 mesh. The shot blasting uses the QZL700 shot blasting machine, and the diameter of the shot blasting pot is 700 mm. The shot blasting speed is 100-200 revolutions (adjusted according to production requirements). Add about 5% coating solution to 100kg core particles to prepare 8kg coating solution. The coating solution is prepared according to the ratio of...

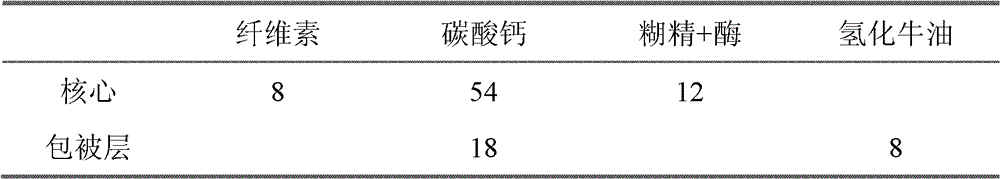

Embodiment 3

[0040] Preparation of granular enzyme for feed for temperature-tolerant pigs:

[0041] Mix 30 kg of xylanase, 10 kg of calcium carbonate, 15 kg of ethyl cellulose, 30 kg of corn starch and 15 kg of water to make a paste. The paste is granulated with a rocking granulator to obtain core granules; the granulator used The model and granulation parameters are the same as in Example 2. The core particles obtained in the granulation step are shot blasted by a shot blasting machine, and finally the particle size of the core particles is controlled at 30-60 mesh. The shot blasting uses the QZL700 shot blasting machine, and the diameter of the shot blasting pot is 700 mm. The shot blasting speed is 100-200 revolutions (adjusted according to production requirements). Add about 5% coating solution to 100kg core particles to prepare 8kg coating solution. The coating solution is prepared according to the ratio of enteric polyacrylic resin emulsion, purified water and premixed powder (1:1.5:0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com