Coated oil and gas well production devices

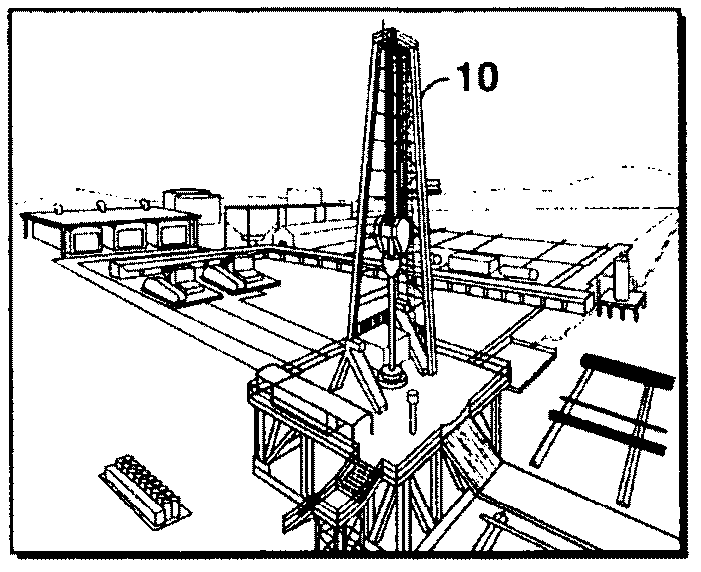

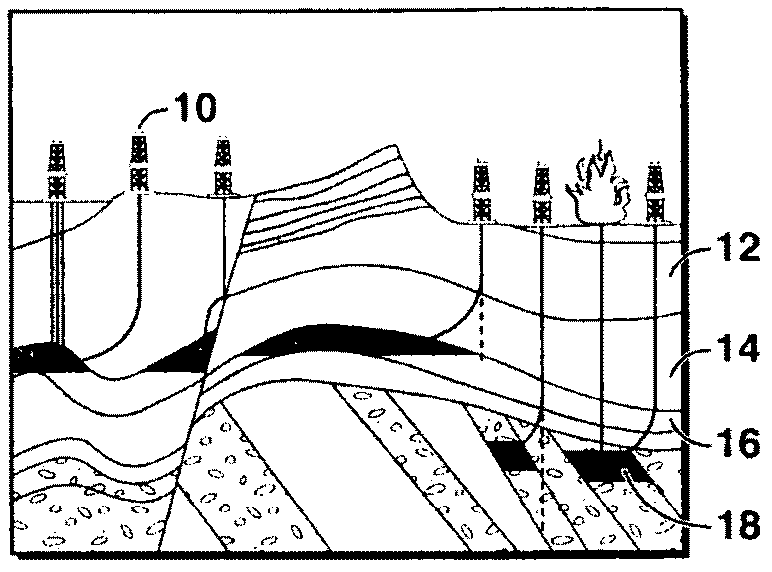

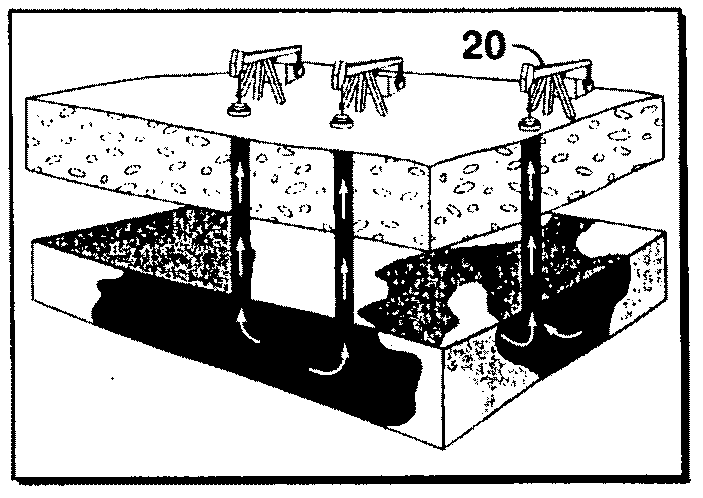

A technology for production devices and oil and gas wells, which is applied to drilling driving devices, drilling equipment, wellbore/well components, etc. in the wellbore, and can solve problems such as excessive friction drag resistance, wellbore restriction, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0269] Illustrative example 1:

[0270] DLC coating was applied on 4142 steel substrate by vapor deposition technique. The DLC coating has a thickness ranging from 1.5 to 25 microns. The hardness was measured to be in the range of 1,300 to 7,500 Vickers hardness numbers. Laboratory tests based on ball-on-disk friction geometry have been performed to demonstrate the friction and wear properties of the coatings. Quartz balls and mild steel balls are used as mating surface materials to simulate open and cased holes, respectively. In an ambient temperature test, DLC coatings and commercial prior art hardfacing coatings were tested against quartz mating facing materials in "dry" or ambient air conditions with a normal load of 300g and a sliding velocity of 0.6m / s to simulate open hole conditions. available in as Figure 19 Improvements in friction performance (reduction in coefficient of friction) of up to 10 times that of uncoated 4142 steel and hardening were achieved in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com