Pressure relief port assembly of gas insulated cabinet

A technology of gas insulation and pressure relief, which is applied in the direction of electrical components, switchgear, and switchgear settings. It can solve problems such as installation difficulties, restrict the design position of pressure relief parts, and increase labor intensity, so as to improve quality and sealing performance. Easy to arrange and combine, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

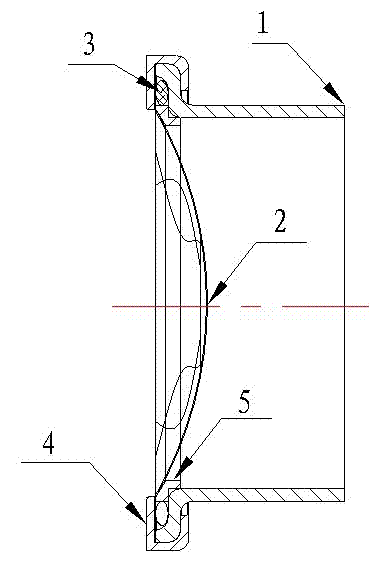

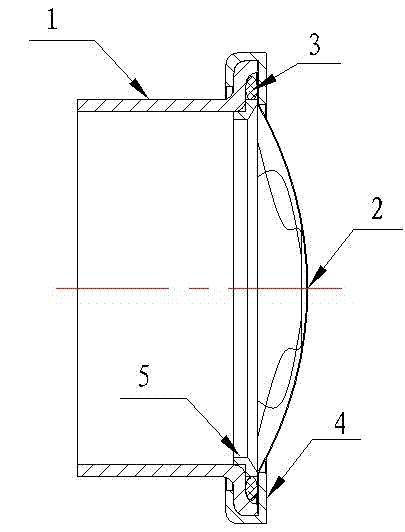

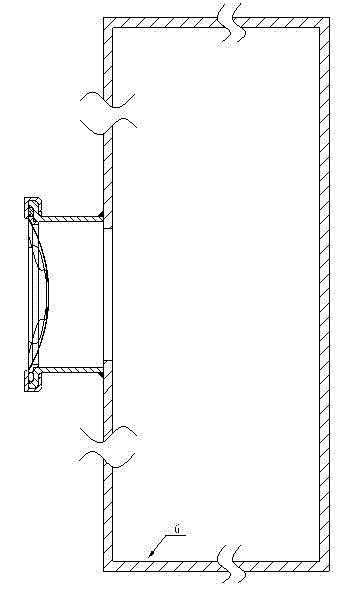

[0020] figure 1 Shown is a schematic diagram of the structure of the external pressure relief port in the present invention. The port is composed of a protective support welding cylinder 1, a pressure relief membrane 2, a sealing O-ring 3, a sealing pressing member 4, and a guide bushing ring 5. The protective support welding cylinder 1 is made of stainless steel or the same base material as that of the air box by stretching through a mold, and is used for sealing and welding on the outer surface of the air box 6. One end is the welding end, and the other end is the sealing installation end. The number of supporting welding cylinders depends on the size of the gas box, one for small-capacity gas boxes; three or two for large-capacity or large-capacity gas boxes. The box is sealed and welded into one. The pressure relief film 2 is made of a thin stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com