Membrane electrode complex of direct methanol fuel cell and preparation method and direct methanol fuel cell thereof

A membrane-electrode composite and methanol fuel cell technology, which is applied in fuel cells, battery electrodes, solid electrolyte fuel cells, etc., can solve problems affecting battery life, stability problems, and DMFC performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

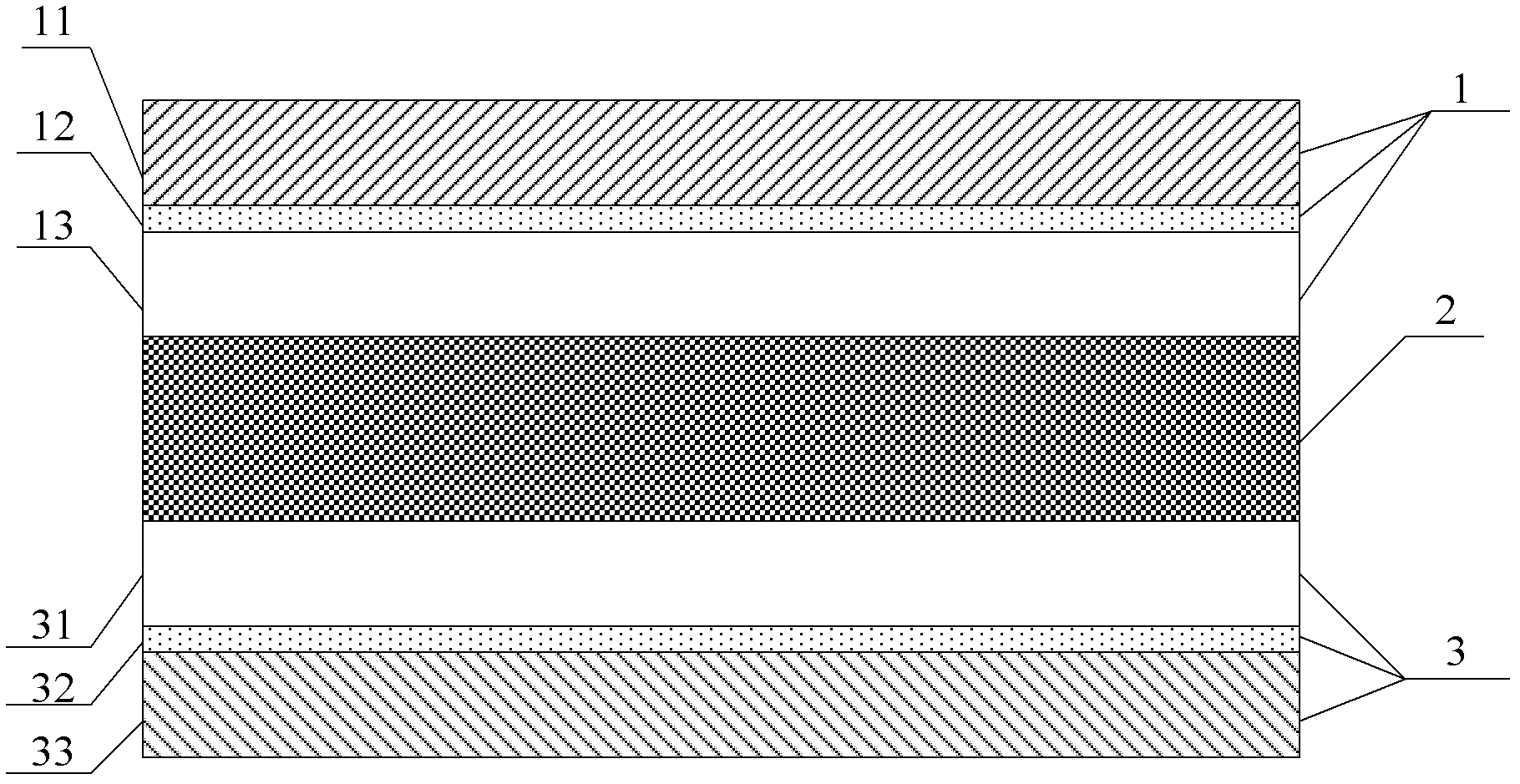

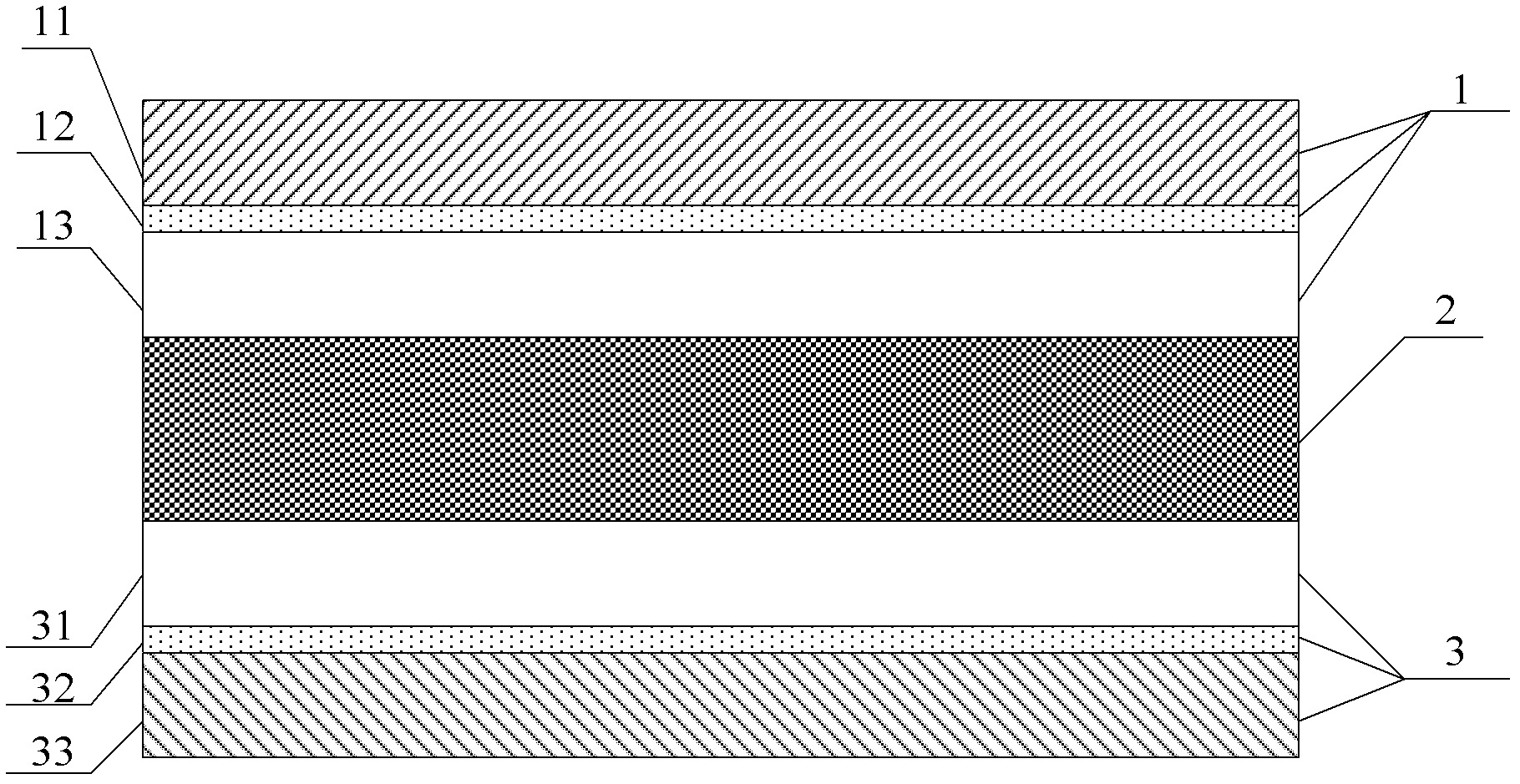

[0044] The present invention also provides a method for preparing the membrane electrode assembly of the above-mentioned direct methanol fuel cell, comprising the following steps:

[0045] Spraying an anode catalyst on the surface of the anode diffusion layer to obtain an anode; spraying a cathode catalyst on the surface of the cathode diffusion layer to obtain a cathode;

[0046] hot-compressing the anode and the anode proton exchange membrane to obtain an anode composite membrane layer; hot-pressing the cathode and the cathode proton exchange membrane to obtain a cathode composite membrane layer;

[0047] The anode composite membrane layer, the liquid electrolyte layer and the cathode composite membrane are fixed, the anode catalyst of the anode composite membrane layer is in contact with the liquid electrolyte, and the cathode catalyst of the cathode composite membrane layer is in contact with the liquid electrolyte layer to obtain a direct methanol fuel cell Membrane elect...

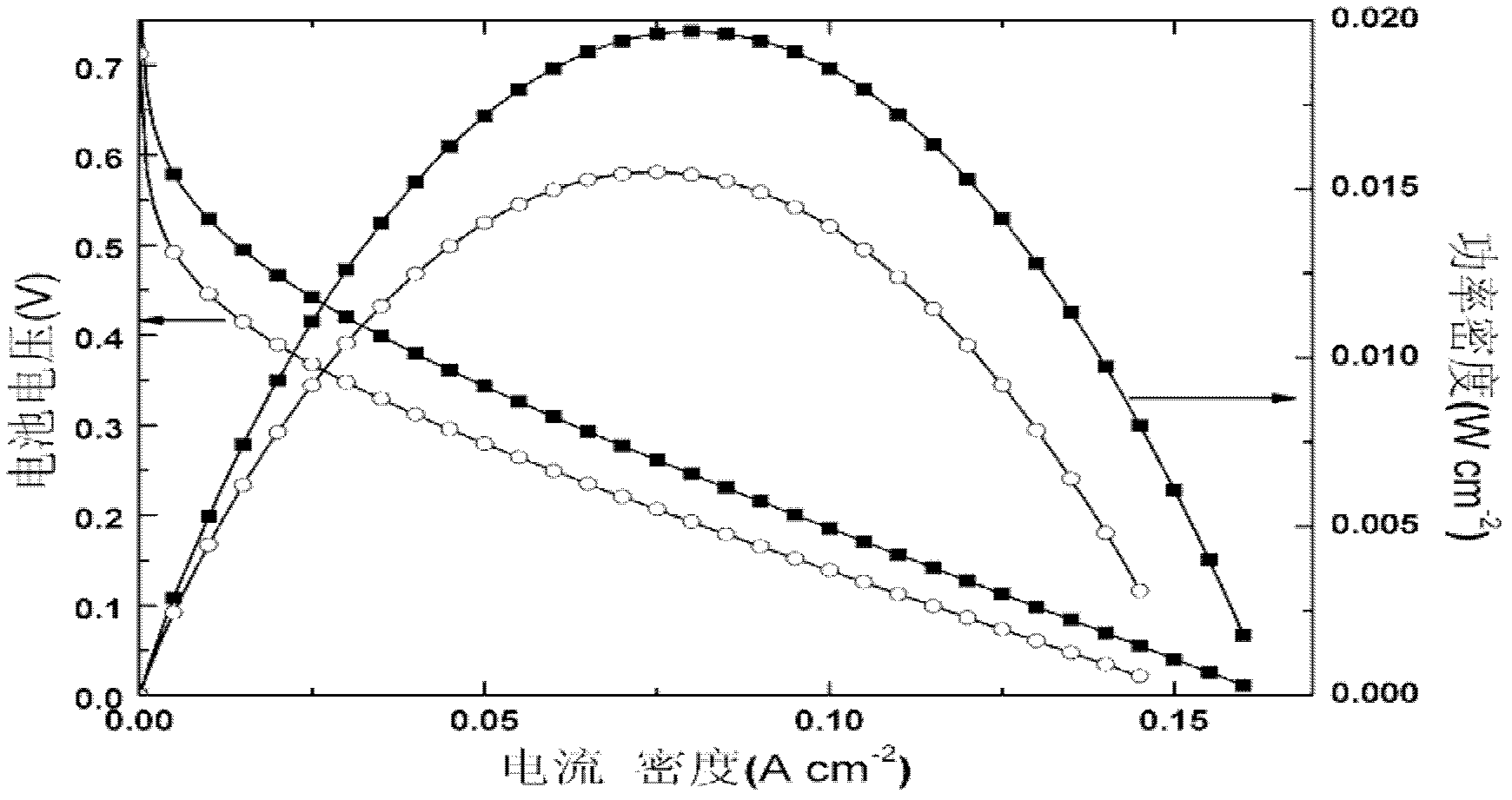

Embodiment 1

[0055] Both the anode proton exchange membrane and the cathode proton exchange membrane used in this example are Nafion 112 perfluorosulfonic acid proton exchange membranes purchased from DuPont, with a thickness of 50 μm;

[0056] Both the anode diffusion layer and the cathode diffusion layer are TGP-H-060 carbon paper purchased from Japan TORAY Company, with a thickness of 0.19mm;

[0057] Both the anode catalyst and the cathode catalyst were electrocatalysts purchased from Johnson Matthey, the cathode side catalyst was Hispec 1000Pt black, the anode side catalyst was Hispec 6000 PtRu black, and the loading capacity was 5 mg / cm 2 .

[0058] The specific operation is as follows:

[0059] 1. Spray the anode catalyst and cathode catalyst evenly on the surface of the anode diffusion layer and the cathode diffusion layer respectively. The thickness of the anode catalyst layer and the cathode catalyst layer are both 10 μm to obtain the anode and cathode with a size of 3cm×3cm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com