Method for manufacturing normally-open temperature-sensitive magnetic control switch

A technology of a magnetic control switch and a manufacturing method, applied in the directions of thermal switch parts, electrical switches, electrical components, etc., can solve the problem that the hysteresis temperature and the operating temperature accuracy cannot reach ≤0.5 ℃, the operating temperature accuracy is poor, and the normally open temperature Problems such as the large size of the sensitive magnetic control switch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

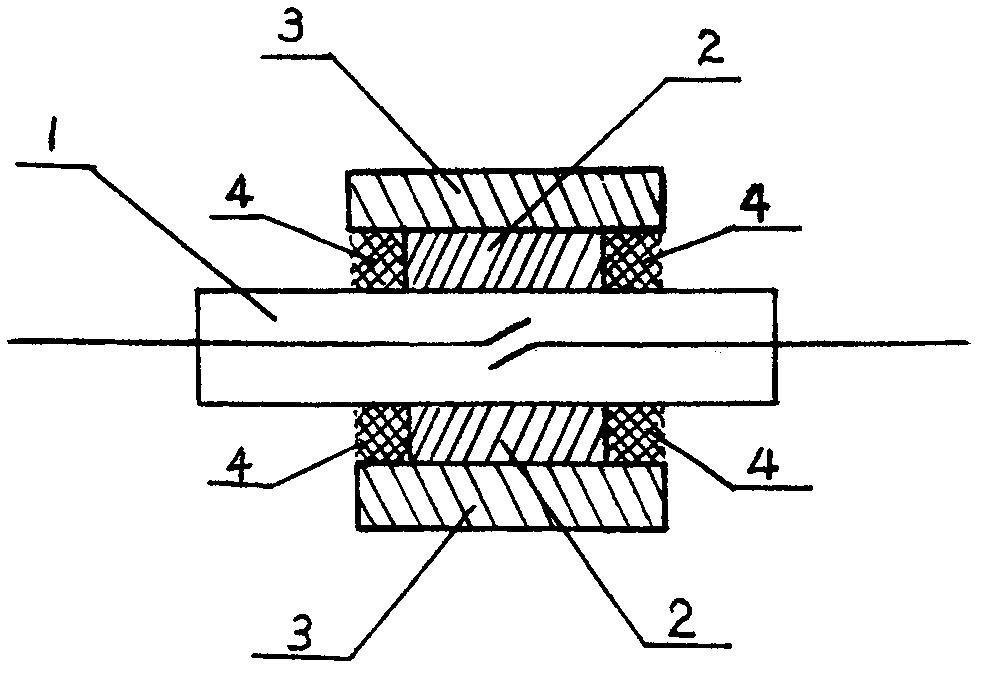

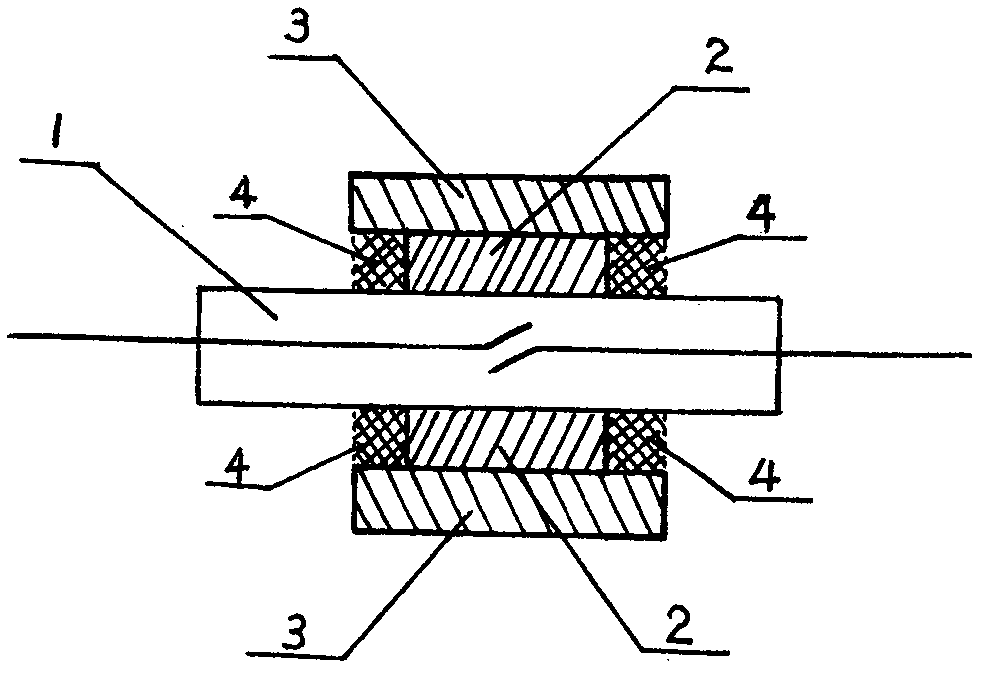

[0013] A method for manufacturing a normally open temperature-sensitive magnetic switch, the structure of which is as follows figure 1 , the temperature-sensitive magnetic control switch is composed of a dry reed switch (1), a permanent magnet magnetic ring (2), and a temperature-sensitive soft magnetic magnetic ring (3). Wherein, the permanent magnetic ring (2) is set in the center of the reed switch (1), and the temperature-sensitive soft magnetic ring (3) is set on the periphery of the permanent magnetic ring (2). The height of the temperature-sensitive soft magnetic ring (3) (the length along the length direction of the reed switch) is greater than the height of the permanent magnetic ring (2). The annular space between the temperature-sensitive soft magnetic magnetic ring (3) and the reed switch (1) is potted with epoxy resin mixed with temperature-sensitive soft magnetic powder (4). In this way, the flux leakage between the permanent magnetic ring (2) and the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com