Self-riveting iron core transformer

An iron core transformer, self-riveting technology, applied in the field of transformers, can solve problems such as cumbersome, rough surface of the iron core, influence on the electrical performance of the iron core, etc., and achieve the effect of smooth surface, good electrical performance consistency, and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

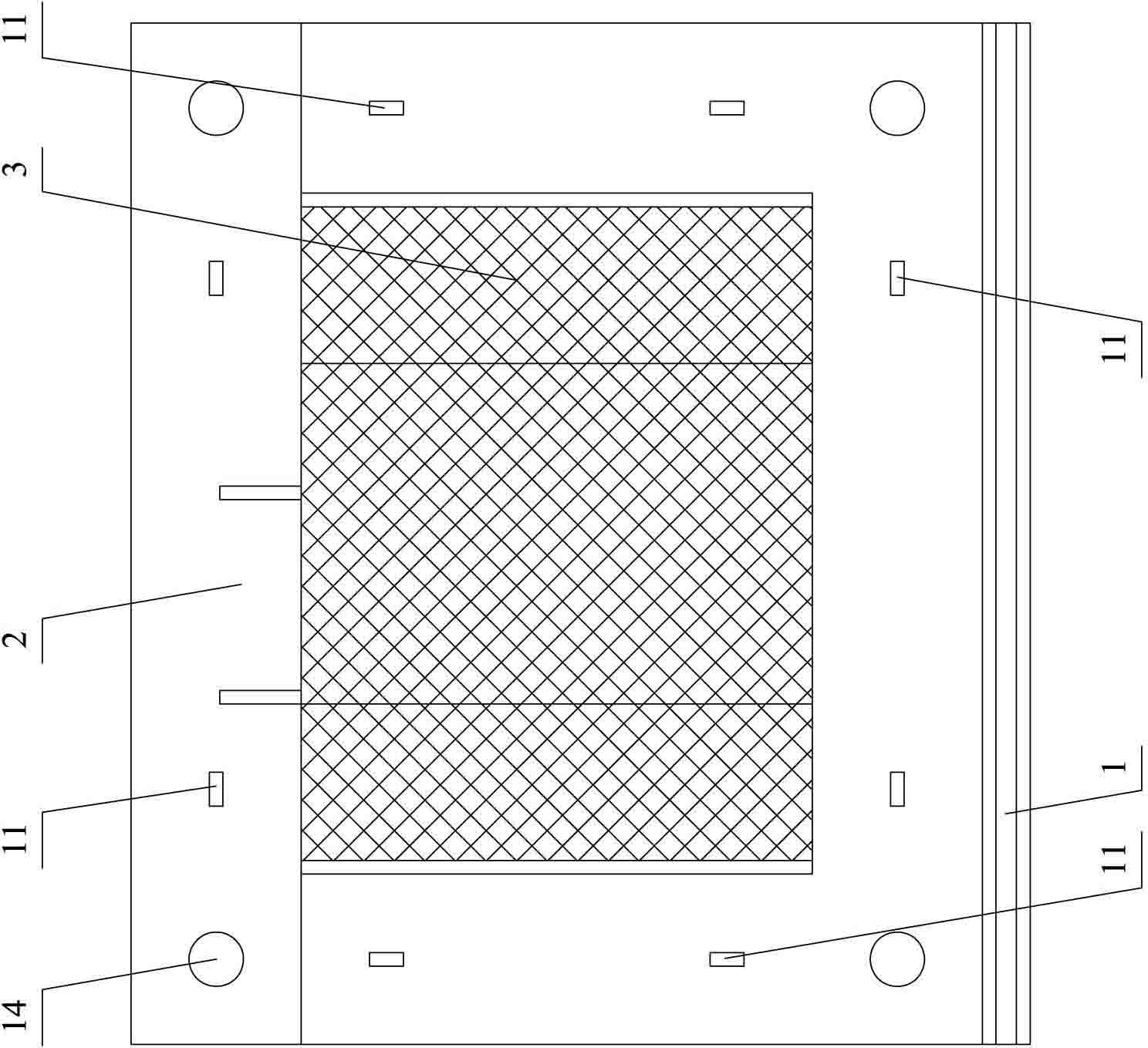

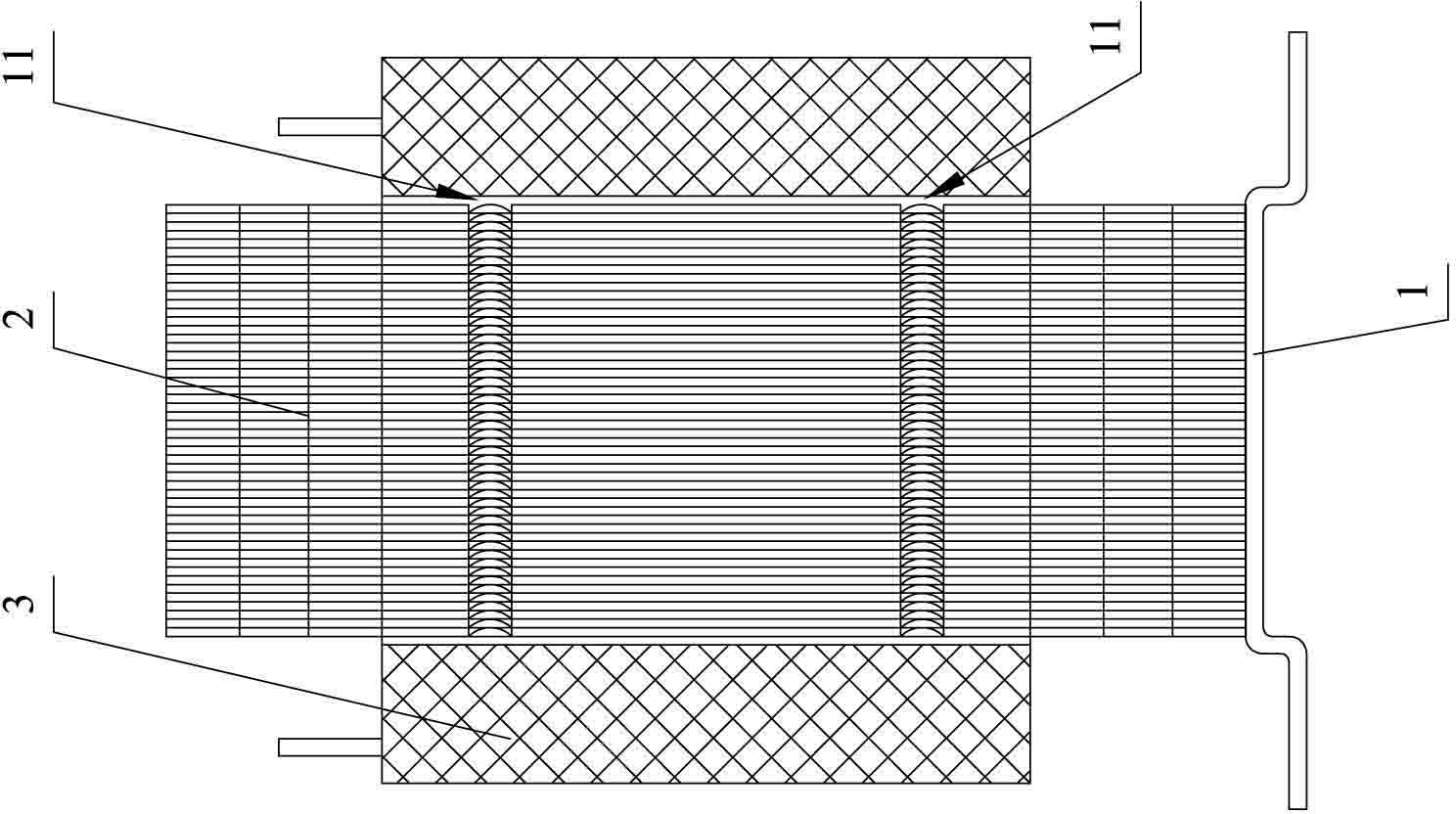

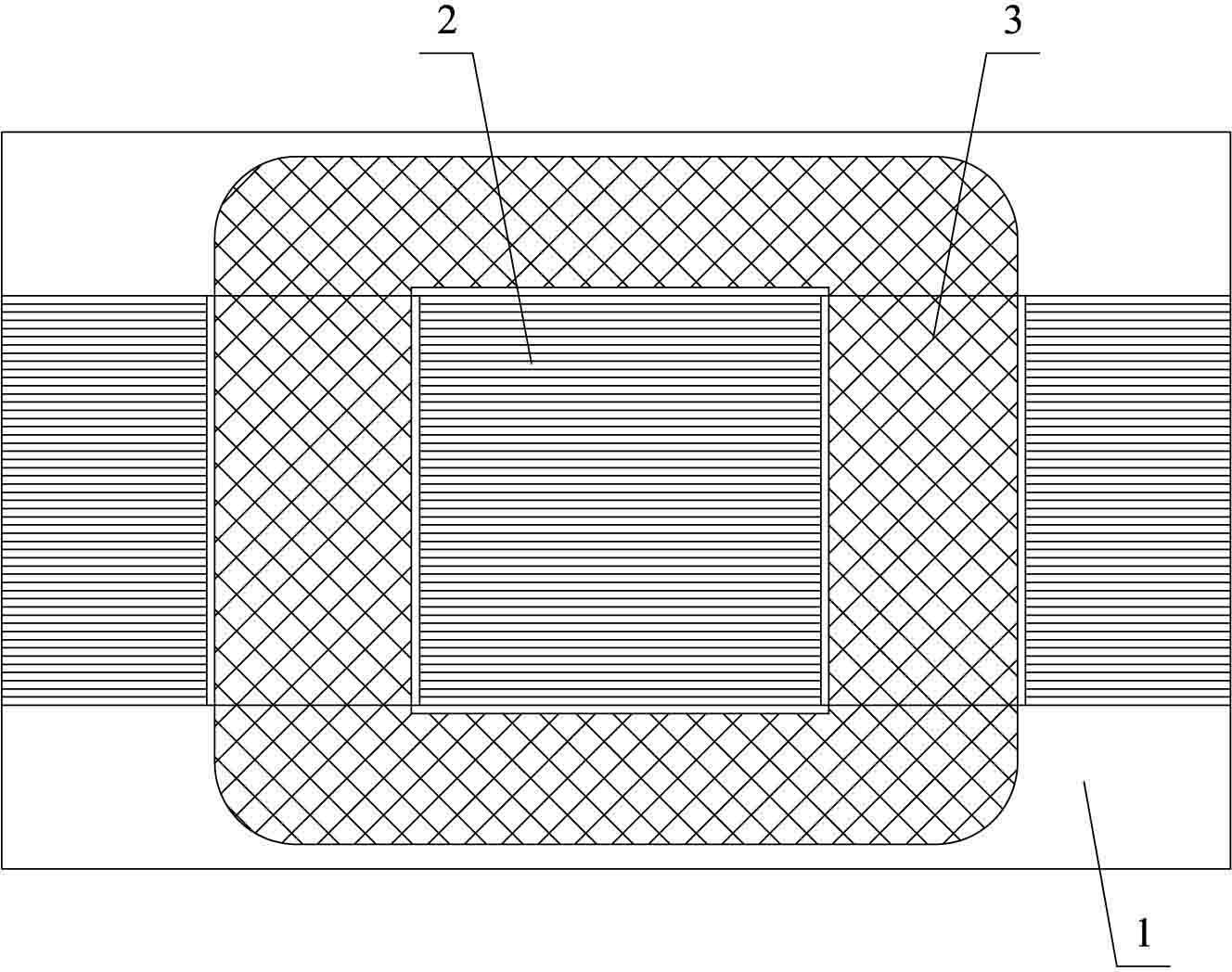

[0021] Embodiment one: see attached figure 1 to attach image 3 shown.

[0022] A self-riveting iron core transformer includes a support 1 , an iron core 2 arranged on the support 1 , and a coil 3 wound on the iron core 2 . The iron core 2 is formed by overlapping and riveting several silicon steel sheets, and the silicon steel sheets are self-riveting silicon steel sheets.

[0023] See attached Figure 4 And attached Figure 5 shown. The self-riveting silicon steel sheet is in the shape of "day" and adopts the combination form of "EI". It includes a central column sheet 5, two side column sheets 6 symmetrically arranged on both sides of the central column sheet 5, a first connecting portion 7 and a second connecting portion connecting the two ends of the central column sheet 5 and the side column sheets 6 8. The self-riveting silicon steel sheet has an opposite first surface 9 and a second surface 10, and a plurality of riveting buckles 11 are symmetrically punched on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com