Intelligent electrical network fiber composite prefabricated branch cable and manufacture method thereof

A technology of optical fiber compounding and prefabricated branches, which is applied in the direction of cable/conductor manufacturing, power cables, cables, etc. It can solve the problems of complex laying schemes and the inability of direct compounding of optical fiber composite cables to enter the home, and the technical requirements are reduced and the mechanical strength is increased. , the effect of equipment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

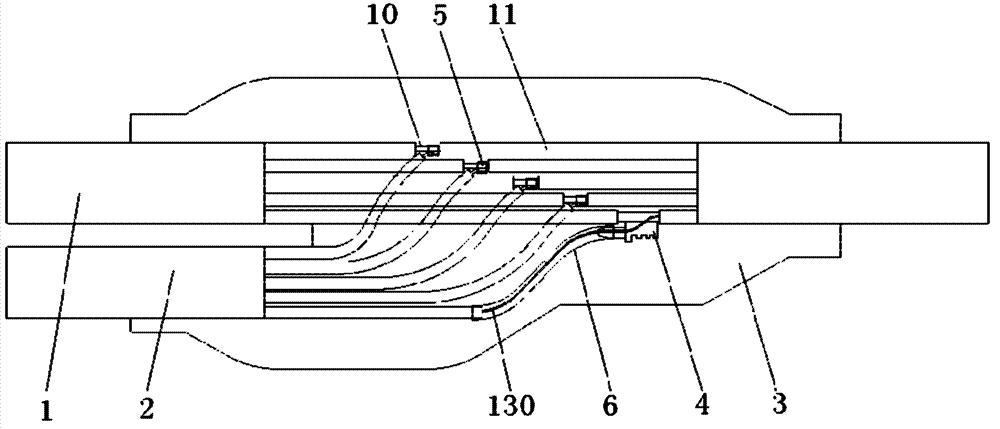

[0031] like figure 1 A smart grid fiber composite prefabricated branch cable shown includes a fiber composite trunk cable 1, a fiber optic composite branch cable 2, and a prefabricated branch complex 3 connecting the fiber optic composite trunk cable 1 and the fiber composite branch cable 2. in:

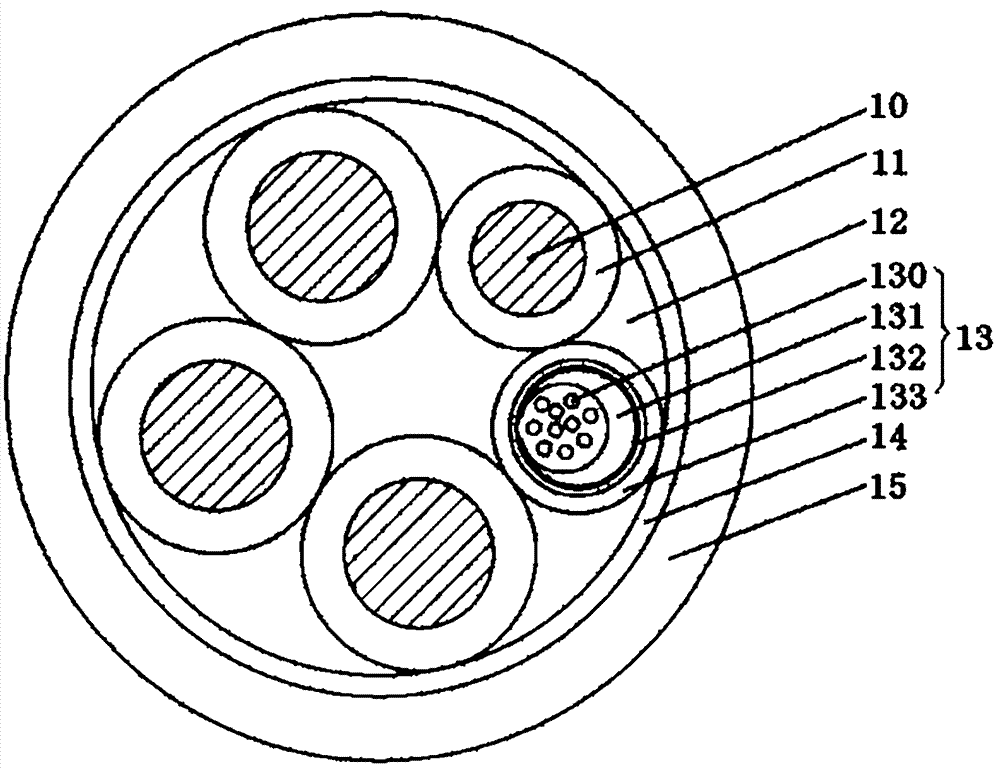

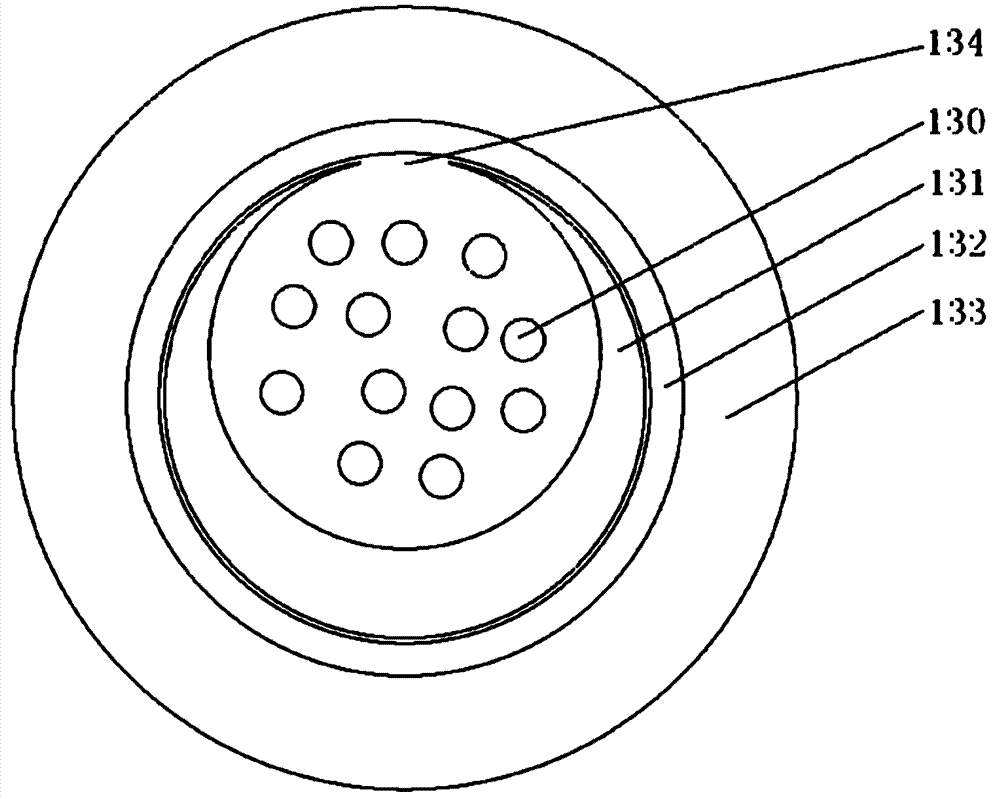

[0032] like figure 2 As shown: the optical fiber composite trunk cable 1 includes one or more conductors 10, an insulating layer 11 extruded outside the conductor 10, a semi-enclosed U-shaped optical cable 12, and an outer layer 12 coated on the insulating layer 11 and the semi-enclosed U-shaped optical cable. A filling layer 12 is filled between the sheath 15, the insulating layer 11, the semi-enclosed U-shaped optical cable 13 and the sheath 15, specifically:

[0033] Conductor 10 is the main carrier for transmitting electricity, and the conductor con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com