Pre-fabricated branch cable

A pre-branch and branch cable technology, applied in the field of power cables, can solve the problems of reliability, poor consistency, difficulty in ensuring insulation strength, high technical requirements, etc., and achieve the effects of safe power supply, superior insulation performance, and many varieties and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

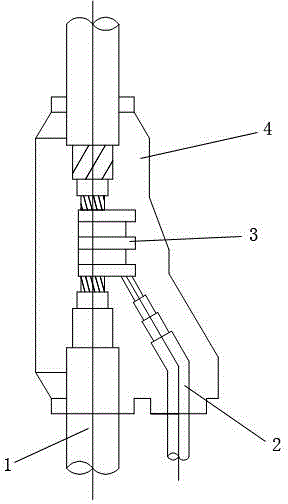

[0015] Such as figure 1 As shown, a kind of pre-branch cable according to the present invention includes a trunk cable 1, a branch cable 2, a connector 3, and a branch sheath 4. The trunk cable 1 and the branch cable 2 are connected together through a connector 3, and the trunk The branch sheath 4 is covered at the branch joint of the cable 1 and the branch cable 2 .

[0016] The above-mentioned trunk cable 1 is a single-core, multi-core or twisted multi-core cable, the twisting direction is left, and there is no intermediate joint in the vertical direction; the branch cable is a single-core cable; the branch protection The sheath is PVC molded insulation, and its thickness is not less than the sum of the trunk cable insulation thickness plus the sheath thickness.

[0017] The present invention provides a pre-branched cable structure and implementation method. The above is only a preferred implementation method of the present invention. It should be pointed out that for those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com