High resolution micro infrared spectrometer based on MEMS scanning micromirror

An infrared spectrometer and scanning micromirror technology, which is used in color/spectral property measurement, spectrometry/spectrophotometry/monochromator, instruments, etc. Reduced movement amplitude, effect of high spectral resolution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

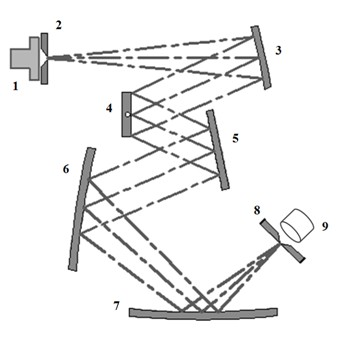

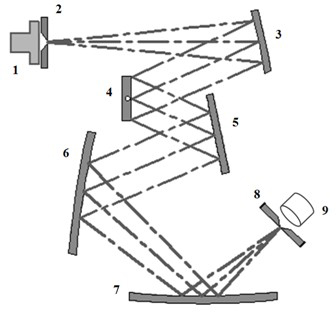

[0023] Such as figure 1 As shown, the spectrometer consists of an optical fiber connection device 1, an incident slit 2, a collimating mirror 3, a scanning micromirror 4 based on MEMS technology, a blazed grating 5, spherical focusing mirrors 6, 7, an exit slit 8 and a unit infrared The detector consists of 9 components. The scanning micromirror 4 based on MEMS technology has a micro optical element that can periodically swing the mirror around a fixed central axis. After the optical signal to be measured enters the spectrometer through the optical fiber connection device 1 and the incident slit 2, it is collimated into a parallel beam by the concave collimating mirror 3, and the mirror surface of the scanning micromirror 4 based on MEMS technology reflects the collimated parallel beam Light of a certain wavelength is diffracted at a specific diffraction angle and then focused to the front of the exit slit 8 by the spherical focusing mirrors 6 and 7, and then output to the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com