Ultrathin-wall steel structure connector and connecting structure

A connection structure and ultra-thin-walled technology, which is applied in the direction of building structure and construction, can solve the problems of insufficient research on the new cold-formed thin-walled steel structure system, unfavorable promotion and application, and lack of independent brands, etc., to achieve good axial restraint performance, Simple and fast operation, strong node integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

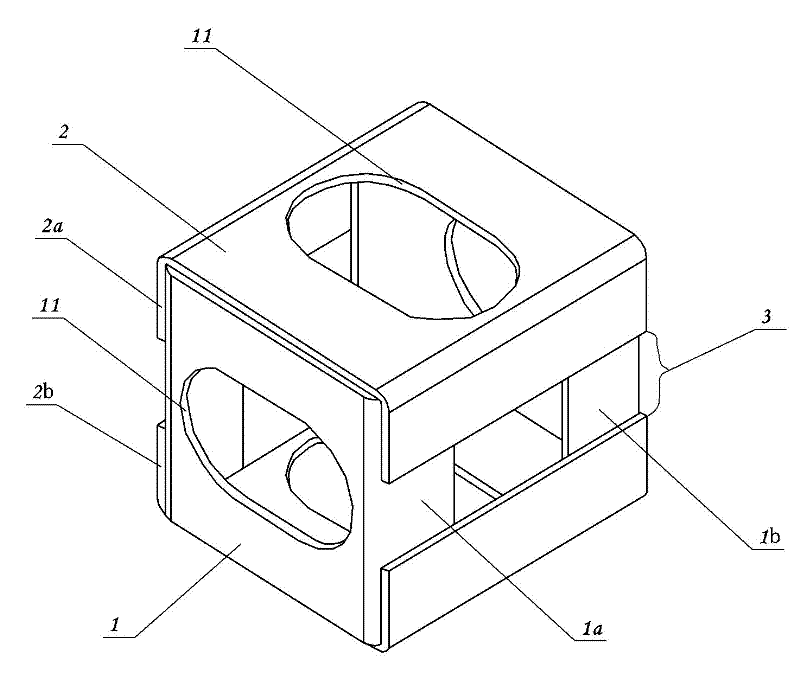

[0041] Embodiment 1: An ultra-thin-wall steel structure column connector, which is a cube or a cuboid connector, and the middle part of the two parallel sides of the connector is provided with a hoop groove 3 .

[0042] See the specific structure figure 1 , the front and rear side plates 1 of the connector are two interlocking channel steels (the wing plates of the front and rear side plates can be in contact or not after buckling), and the upper and lower side plates 2 are two interlocking but not in contact channel steel, the upper and lower channel steel flanges 2a and 2b on both sides are fixed on the outer sides of the front and rear channel steel flanges 1a and 1b, wherein the non-contact parts between the upper and lower channel steel flanges form hoop grooves 3.

[0043] In addition, the webs of the front and rear channel steel 1 and the upper and lower channel steel 2 are provided with matching lightening holes.

Embodiment 2

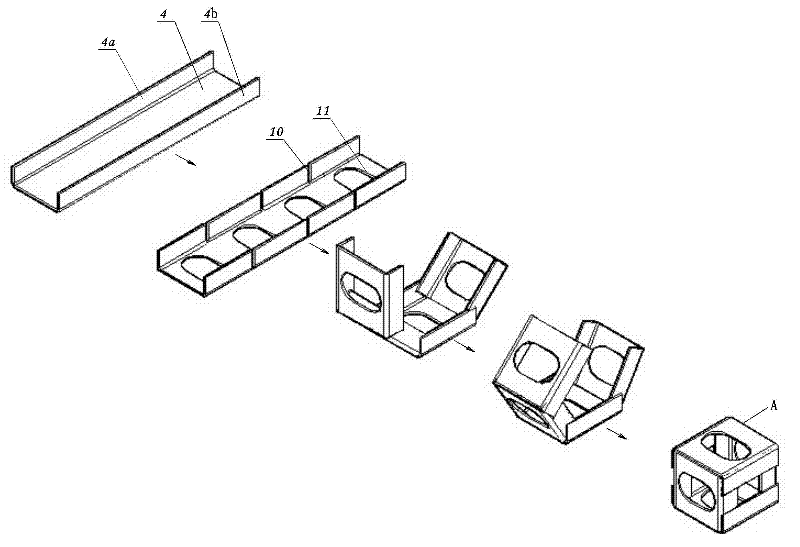

[0044] Embodiment two: see figure 2 , is a folding composition method of the connector described in the first embodiment. The connecting piece is formed by folding a whole strip-shaped channel steel plate 4, and the folding steps are as follows: (1) Make three pairs of groove-shaped grooves 10 respectively on both side symmetrical wing plates 4a and 4b of the strip-shaped channel-shaped steel plate 4 Form four pairs of sub-wings, and meet the requirement that the length of the first and third pair of sub-wings is the same, and the length of the second and fourth pair of sub-wings is the same; at the same time, set matching The lightening hole (2) is folded inwards to form a cube or a cuboid with the straight line where the opposite grooves are located on both sides as the folding edge, and the first and third pair of sub-wings are located on the outside, and the second and fourth pair of sub-wings are located on the inside , the outer and inner sub-wings are respectively fix...

Embodiment 3

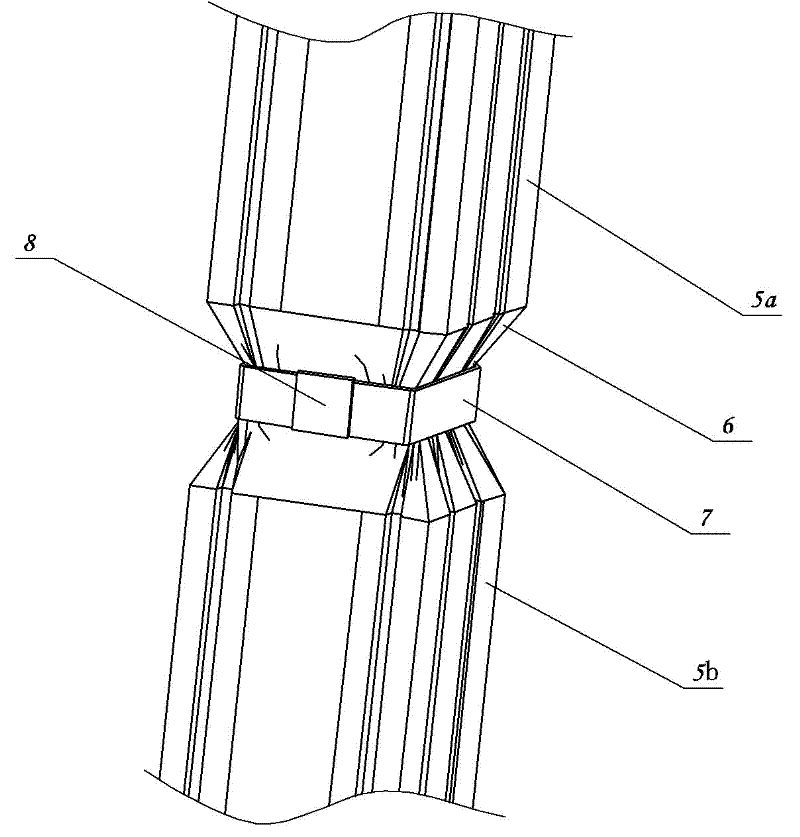

[0045] Embodiment three: see image 3 , a connection structure of an ultra-thin-walled steel column, comprising two hollow ultra-thin-walled steel columns 5a and 5b, the ends of the two hollow ultra-thin-walled steel columns are respectively inserted into the outside of the connector A, and the two sections are hollow The ultra-thin-walled steel column is hooped in the hoop groove 3 of the connector at the same time.

[0046] The width of the clamping steel strip 7 is slightly smaller than the width of the connecting member hoop groove 3 .

[0047] The above connection process is as follows: first use the tightening tool to compress the end of the first hollow ultra-thin-walled steel column 5a to the outside of the connector A hoop groove 3, and then use the tightening tool to compress the end of the second hollow ultra-thin-walled steel column 5b Compress to the outside of the first hollow ultra-thin-walled steel column 5a, set the clamping steel belt 7 on the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com