Preparation method of polycarboxylic acid high-efficiency water reducer

The technology of high-efficiency water-reducing agent and polycarboxylic acid is applied in the field of water-reducing agent for concrete, which can solve the problems of long reaction period and high temperature, and achieve the effects of short reaction period, shortened reaction period and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

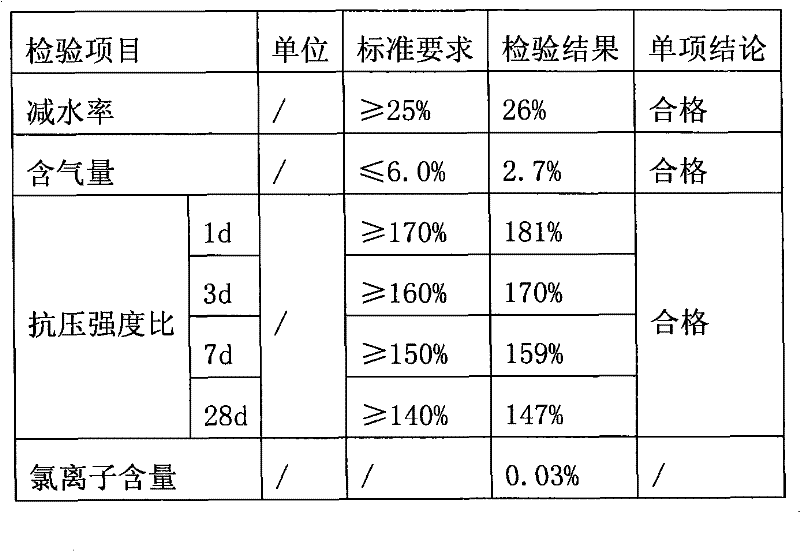

Examples

Embodiment 1

[0019] The preparation method of polycarboxylic acid high-efficiency water reducer, first mix 600 parts of water, 350 parts of methallyl polyoxyethylene ether and 8 parts of sodium methacryl sulfonate, then heat up to 70 ° C, and then one-time Add 35 parts of acrylic acid, 3 parts of ammonium persulfate, 2 parts of acrylamide and 2 parts of thioglycolic acid, and keep warm for 1 hour to obtain the polycarboxylate superplasticizer.

Embodiment 2

[0021] The preparation method of polycarboxylic acid high-efficiency water reducer, first mix 600 parts of water, 300 parts of methallyl polyoxyethylene ether and 6 parts of sodium methacryl sulfonate, then heat up to 55 ° C, and then Add 30 parts of acrylic acid, 2 parts of ammonium persulfate, 1 part of acrylamide and 1 part of thioglycolic acid, and keep warm for 1 hour to obtain the polycarboxylate superplasticizer.

Embodiment 3

[0023] The preparation method of polycarboxylic acid high-efficiency water reducer, first mix 650 parts of water, 400 parts of methallyl polyoxyethylene ether and 10 parts of sodium methacryl sulfonate, then heat up to 60 ° C, and then one-time Add 40 parts of acrylic acid, 4 parts of ammonium persulfate, 3 parts of acrylamide and 3 parts of thioglycolic acid, and keep it warm for 1 hour to obtain the polycarboxylate superplasticizer.

[0024] The polycarboxylate superplasticizer obtained in the above examples is a colorless and transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com