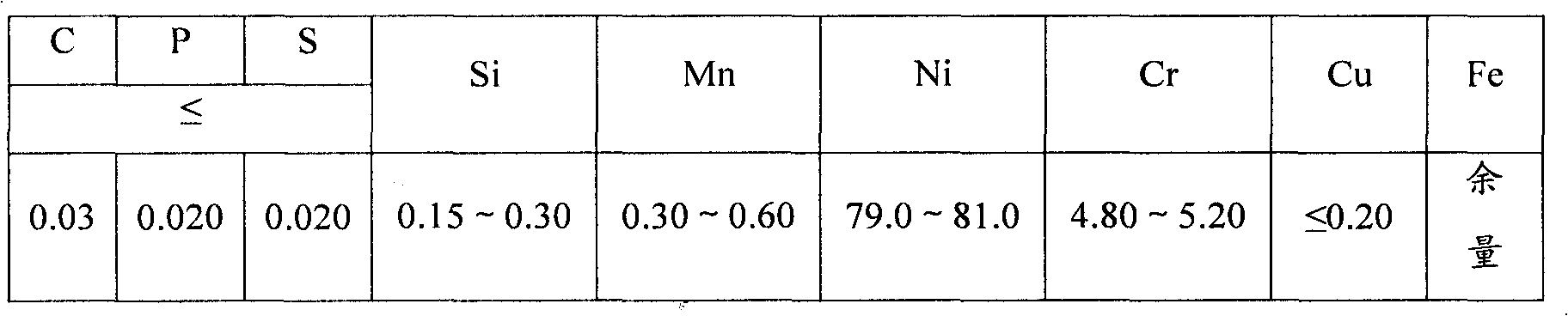

Free forging method for nickel-based magnetically soft alloy slab

A soft magnetic alloy, nickel-based technology, applied in metal processing equipment and other directions, can solve problems such as the inability to forge large aspect ratio forging billets, and achieve the effect of improving product plasticity, reducing tonnage, and ensuring forging time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, electroslag ingots are used as raw materials. The size of the electroslag ingots is 300 mm in diameter, 787 mm in length, 445 kg in weight, and 2.6 in length / diameter.

[0049] Put the electroslag ingot above into a gas furnace and heat it to 1315°C. The above-mentioned electroslag ingot is subjected to upsetting and square forging on an electro-hydraulic hammer. When the temperature drops to 1050°C to 1100°C, the forging billet is reheated to 1315°C in a gas furnace, and then the square forging is repeated. The process of heating and then squaring was carried out three times in total to obtain a square forging billet with a section size of 210×210 mm, a length of 1070 mm, and a billet weight of 378 kg.

[0050] The above-mentioned square forging blank was reheated to 1315°C in a gas furnace, and then stretched and flattened forged on an electro-hydraulic hammer. When the temperature drops to 1050°C to 1100°C, the forging billet is reheated to 1315...

Embodiment 2-7

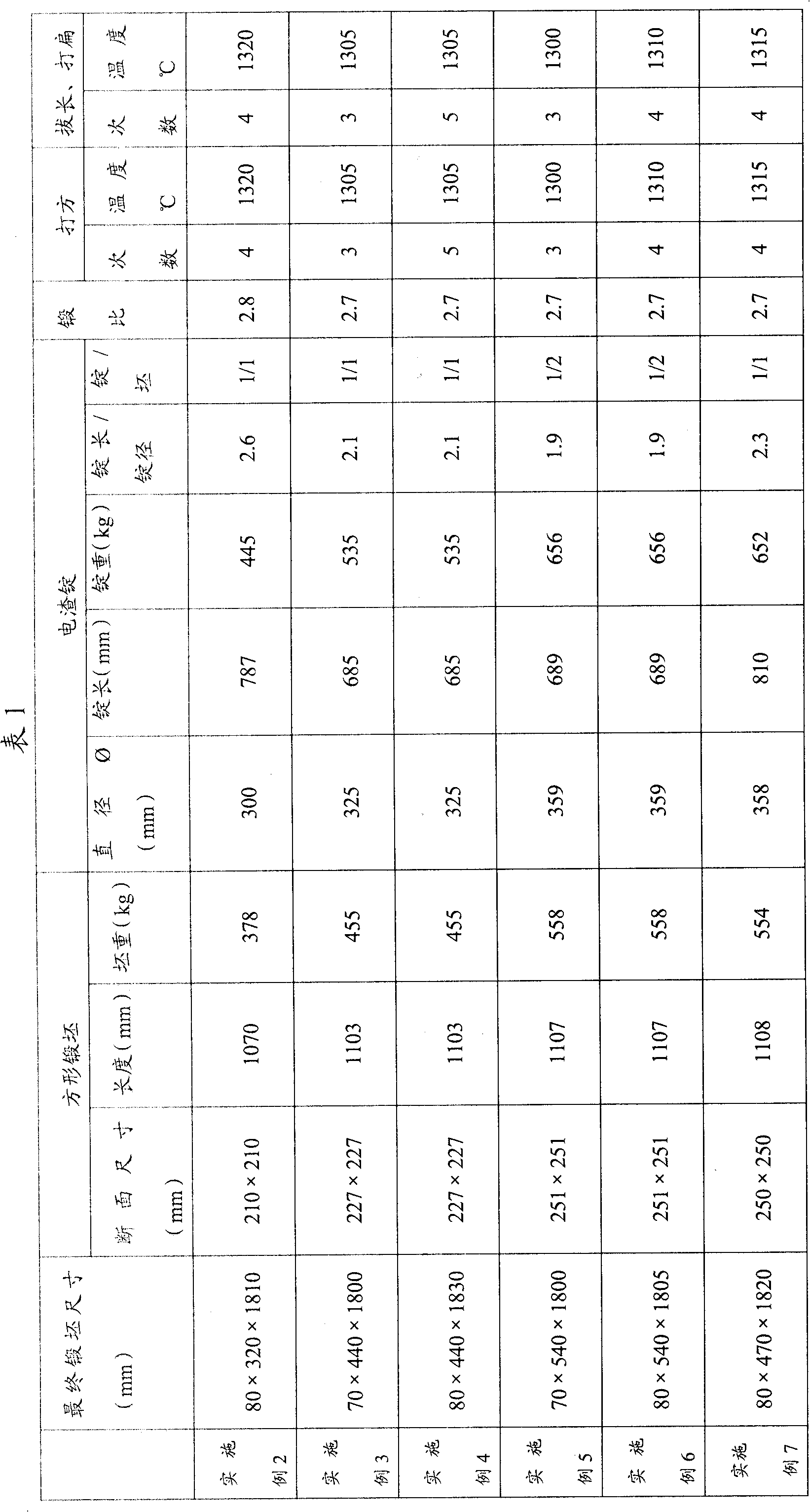

[0053] Examples 2-7 used basically the same process conditions as in Example 1 to prepare forging blanks, and the changed material parameters are shown in Table 1.

[0054]

Embodiment 8

[0056] The present embodiment adopts peeling ingot as raw material, and the size of this peeling ingot is the front diameter 314mm of peeling, and the length of ingot is 858mm, and the weight of ingot is 518kg, and the length of ingot / diameter of ingot is 2.7. The surface scars produced by melting and casting are removed from the above-mentioned peeling ingot. After the treatment, the peeling ingot size specification is 300mm in diameter, 858mm in length, and 473kg ingot weight.

[0057] Put the peeled ingot after the above treatment into an electric heating furnace and heat it to 1315°C. On the electro-hydraulic hammer, the above peeled ingot is subjected to upsetting and square forging. When the temperature drops to 1050°C to 1100°C, reheat the forging billet to 1315°C in an electric heating furnace, and then repeat square forging. The process of heating and then squaring was carried out 4 times in total to obtain a square forging billet with a cross-sectional size of 210×2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com